PACE Evolution: Revolutionizing Natural Product Drug Discovery with Phage-Assisted Continuous Evolution

This article provides a comprehensive guide for researchers on leveraging Phage-Assisted Continuous Evolution (PACE) to evolve and optimize enzymes for natural product biosynthesis.

PACE Evolution: Revolutionizing Natural Product Drug Discovery with Phage-Assisted Continuous Evolution

Abstract

This article provides a comprehensive guide for researchers on leveraging Phage-Assisted Continuous Evolution (PACE) to evolve and optimize enzymes for natural product biosynthesis. We cover foundational principles, methodological setups for evolving polyketide synthases (PKSs) and non-ribosomal peptide synthetases (NRPSs), troubleshooting common experimental challenges, and validating evolved systems against traditional methods. The content synthesizes current literature and protocols to empower scientists in accelerating the development of novel bioactive compounds for therapeutic applications.

What is PACE? Core Principles and Why It's a Game-Changer for Natural Products

Application Notes

Phage-Assisted Continuous Evolution (PACE) is a powerful directed evolution platform that enables rapid, automated evolution of biomolecules. Within the context of natural products research, PACE offers a transformative approach to evolve enzymes involved in biosynthetic pathways (e.g., polyketide synthases, non-ribosomal peptide synthetases), regulatory proteins for pathway engineering, or therapeutic peptides and proteins derived from natural scaffolds. The system's continuous nature allows for the exploration of vast mutational landscapes in remarkably short timeframes (weeks), accelerating the development of novel catalysts or bioactive compounds with improved properties.

Core Machinery & Function:

- M13 Filamentous Phage Vector: The gene of interest (GOI) to be evolved is inserted into a modified M13 phage genome, replacing the gene for the essential pIII protein. Phage propagation becomes dependent on the evolving GOI's activity, creating a direct link between desired function and survival.

- Host E. coli (Lagoonal Cells): Continuously diluted host cells are maintained in a fixed-volume vessel (lagoon). These cells supply the resources for phage replication and contain accessory plasmids (see below).

- Mutagenesis Plasmid (MP): Harbored in the host cells, this plasmid expresses mutagenesis proteins (e.g., a variant of the DNA polymerase III α subunit) to introduce targeted mutations specifically into the replicating phage DNA, generating genetic diversity for selection.

- Accessory Plasmid (AP): Also in the host cells, this plasmid links the desired activity of the GOI to phage propagation. It expresses a host survival factor (e.g., the missing pIII) only when the evolving GOI performs its target function (e.g., binding a new ligand, catalyzing a reaction).

Key Quantitative Parameters: The efficiency of PACE is governed by several critical parameters, which must be optimized for each evolution campaign.

Table 1: Key Quantitative Parameters in a Typical PACE Experiment

| Parameter | Typical Range | Function & Impact |

|---|---|---|

| Lagoon Dilution Rate | 1.0 - 1.3 vol/hr | Controls host cell doubling time and phage residence time. Must exceed host growth rate to prevent takeover. |

| Host Cell Density | 10^8 - 10^9 cfu/mL | Ensures sufficient resources for continuous phage replication and evolution. |

| Phage Titer in Lagoon | 10^9 - 10^11 pfu/mL | Indicator of successful selection. A stable, high titer suggests functional GOI variants are propagating. |

| Mutation Rate (MP induced) | ~10^-5 mutations/bp/ gen | Balances exploration of sequence space with preservation of functional sequences. Tunable via MP expression. |

| Experiment Duration | 50 - 500 hours | Allows for 10s to 100s of phage generations, enabling significant evolution. |

Experimental Protocols

Protocol 1: Establishing a Basic PACE Lagoon for Evolved Binding Affinity

Objective: To set up a continuous evolution lagoon to evolve a protein (e.g., a transcription factor derived from a natural product biosynthetic pathway) for binding to a novel small-molecule inducer.

Materials:

- "Scientist's Toolkit" (See Table 2)

- Peristaltic pump system

- Aeration system with sterile air filter

- Lagoon vessel (e.g., water-jacketed glass vessel)

- Media waste container

Procedure:

- Pre-culture Host Cells: Inoculate E. coli cells harboring the MP and the custom AP (where pIII expression is driven by the transcription factor's target promoter) into 5 mL LB with appropriate antibiotics. Grow overnight at 37°C, 250 rpm.

- Dilution and Induction: Subculture the overnight culture 1:1000 into fresh 1L of PACE medium (LB with antibiotics, 0.1% glucose, 0.2% arabinose to induce MP). Incubate at 37°C, 250 rpm until OD600 reaches ~0.5.

- Lagoon Priming: Transfer the induced host cell culture to the sterile lagoon vessel. Begin medium inflow and waste outflow using the peristaltic pump set to the target dilution rate (e.g., 1.1 vol/hr). Begin aeration. Allow the lagoon to equilibrate for 30-60 minutes.

- Phage Infection: Introduce the initial M13 phage library (harboring the wild-type or mutagenized gene for the transcription factor) to the lagoon. The initial Multiplicity of Infection (MOI) should be ~0.001-0.01.

- Monitoring: Collect effluent samples every 4-8 hours.

- Measure phage titer by plaque assay on appropriate E. coli indicator cells.

- Measure host cell density by plating for colony-forming units (cfu).

- Monitor for contamination.

- Harvesting: Once phage titer stabilizes at a high level (>10^10 pfu/mL) for >24 hours, harvest effluent phage particles via PEG precipitation. Isolate phage genomic DNA and sequence the evolved GOI from the population or individual plaques.

Protocol 2: Phage Titer Determination via Plaque Assay

Objective: To quantify infectious phage particles from lagoon samples.

Procedure:

- Prepare a 1:10 serial dilution series (up to 10^-12) of the lagoon sample in Phage Dilution Buffer.

- Mix 100 µL of selected dilutions with 1 mL of fresh, log-phase E. coli host cells (without AP/MP, but expressing pIII for infection).

- Incubate at 37°C for 10 minutes without shaking to allow phage adsorption.

- Add the infected cell mixture to 5 mL of molten (45°C) top agar, vortex briefly, and pour onto pre-warmed LB-agar plates. Swirl to distribute evenly.

- Let the top agar solidify, then invert plates and incubate at 37°C overnight.

- Count plaques on plates with 10-100 distinct plaques. Calculate titer: Plaque-Forming Units (pfu)/mL = (Plaque count) / (Dilution factor × Volume plated in mL).

Table 2: The Scientist's Toolkit - Essential Research Reagents for PACE

| Item | Function in PACE |

|---|---|

| M13 Phage Vector (e.g., pSEVA-phage) | Engineered phage genome backbone for GOI insertion and propagation. |

| Accessory Plasmid (AP) Library | Encodes the conditional pIII system; design defines the selection pressure. |

| Tunable Mutagenesis Plasmid (MP) | Expresses inducible mutator proteins to diversify the phage-borne GOI. |

| PACE-Competent E. coli (e.g., S2060) | F-pili expressing, endonuclease I-deficient host strain for robust phage production. |

| Lagoon Medium (LB + Additives) | Supports continuous host growth. Contains antibiotics, arabinose (MP inducer), and any selection ligands. |

| Phage Precipitation Solution (PEG/NaCl) | For concentrating and purifying phage particles from lagoon effluent for analysis. |

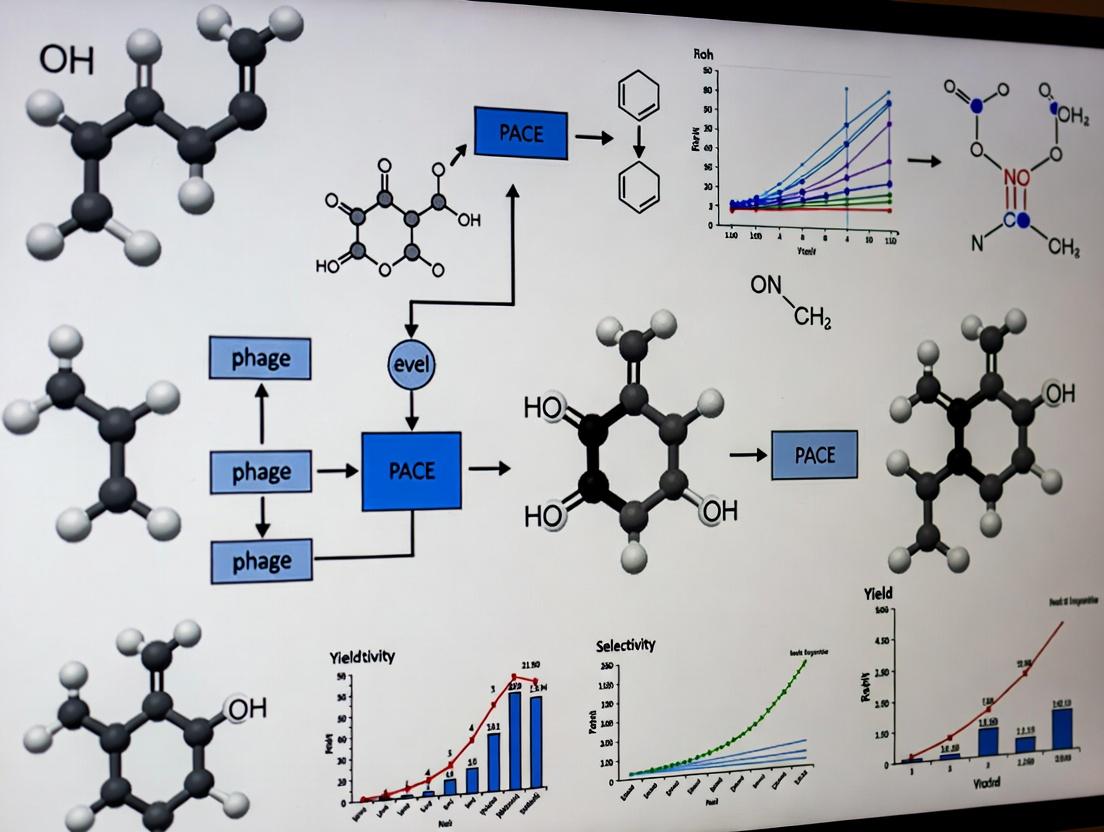

Diagrams

Title: PACE Lagoon Continuous Flow & Replication Cycle

Title: Core PACE Selection Logic & Genetic Circuitry

Application Notes

The discovery of novel natural products (NPs) via traditional methods is constrained by evolutionary bottlenecks. These bottlenecks manifest in the core biosynthetic machinery: Polyketide Synthases (PKSs), Nonribosomal Peptide Synthetases (NRPSs), and Terpene Synthases (TSs). Key challenges include low expression yields in heterologous hosts, poor solubility, inability to functionally reconstitute megasynth(et)ases, substrate promiscuity limitations, and the vastness of unexplored sequence-function space.

The integration of Phage-Assisted Continuous Evolution (PACE) offers a paradigm shift. PACE applies continuous, directed evolution pressure in vivo to overcome these bottlenecks by evolving the biosynthetic enzymes themselves. The following Application Notes detail how PACE can be applied to each system.

Table 1: Core Challenges and PACE-Addressable Solutions

| Biosynthetic System | Primary Bottleneck | PACE-Evolvable Trait | Desired Evolutionary Outcome |

|---|---|---|---|

| Modular PKS/NRPS | Stalling, mis-incorporation, poor inter-domain communication. | Protein-protein interaction specificity, carrier domain (ACP/PCP) efficiency. | Improved chimeric assembly line fidelity and titer. |

| Iterative PKS/TS | Limited substrate promiscuity, poor regioselectivity/stereoselectivity. | Active site architecture, substrate channel geometry. | Novel chemical scaffolds, altered cyclization patterns. |

| All Systems | Host toxicity, poor solubility/expression, precursor limitation. | Enzyme stability, solubility tags, resistance to host defenses. | High-yield production in optimized chassis (e.g., E. coli, S. cerevisiae). |

Protocols

Protocol 1: PACE Setup for Evolving a Type I PKS Module Solubility inE. coli

Objective: Evolve a poorly soluble PKS module for functional expression in E. coli using PACE with a solubility reporter.

Materials (Research Reagent Solutions):

- M13 Phage Vector: Harbors gene III (pIII) under control of a weak constitutive promoter and the PKS module gene as a C-terminal fusion to a fragment of pIII.

- Accessory Plasmid (AP): Encodes the remaining, essential fragment of pIII. Functional pIII (required for phage infectivity) only assembles if the PKS module is soluble and allows fusion fragment folding.

- Selection Plasmid (SP): Contains the mutagenesis genes (e.g., mutagenic plasmid MP6 from PACE Manual).

- Host E. coli strain: Lagoon host (e.g., S2060) for continuous culture.

- Terrific Broth (TB) Medium: For high-density bacterial growth.

- Antibiotics: Chloramphenicol (for AP), Spectinomycin (for SP), Carbenicillin (for phage selection).

- Induction Agent: Isopropyl β-d-1-thiogalactopyranoside (IPTG) for tunable expression of the PKS-pIII fusion.

Methodology:

- Clone the target PKS module into the M13 PACE vector, creating an in-frame fusion with the pIII fragment.

- Transform the AP and SP into the E. coli lagoon host strain. Inoculate a 500 mL lagoon with this strain in TB medium with appropriate antibiotics.

- Initiate the lagoon culture in the PACE apparatus (constant dilution with fresh medium, typically 1 lagoon volume per hour).

- Infect the lagoon with the initial library of M13 phage carrying the PKS module (~10^8 PFU/mL).

- Allow continuous evolution for 24-72 hours. Phage producing soluble PKS-pIII fusions will generate infectious progeny; those with insoluble aggregates will not.

- Harvest phage from lagoon effluent. Isolate viral ssDNA, sequence the evolved PKS gene, and reclone into an expression vector for soluble protein production and biochemical characterization.

Protocol 2: Evolving Terpene Synthase Substrate Promiscuity via PACE

Objective: Evolve a terpene synthase to accept non-natural allylic diphosphate substrates, linking activity to phage propagation.

Materials (Research Reagent Solutions):

- PACE-Compatible Phage: M13 with TS gene replacing pIII. pIII expression is controlled by a biosensor responsive to a target terpene product.

- Biosensor Plasmid (BP): Encodes a transcription factor that specifically binds the desired terpene product and activates pIII expression.

- Substrate Feedstock: Non-natural allylic diphosphate (e.g., 12-carbon farnesyl diphosphate analog) supplied in the lagoon medium.

- Host E. coli with Precursor Pathway: Engineered to overproduce isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP).

- Liquid Chromatography-Mass Spectrometry (LC-MS): For product verification.

Methodology:

- Construct the BP with a pIII gene under a promoter containing binding sites for a terpene-responsive transcription factor (e.g., engineered E. coli TetR).

- Establish a lagoon with E. coli harboring the BP, SP, and the endogenous MEP pathway for IPP/DMAPP.

- Start continuous culture with the non-natural substrate analog in the feed medium.

- Infect with the TS phage library. Only phage whose TS enzymes produce the terpene that activates the biosensor will propagate.

- Run PACE for multiple days. Periodically sample effluent for phage titer and analyze terpene production via LC-MS from host cell pellets.

- Isolve and sequence evolved TS variants. Characterize kinetic parameters (Km, kcat) with both natural and non-natural substrates.

Diagrams

Diagram Title: PACE Workflow for NP Enzyme Evolution

Diagram Title: PACE Solubility Selection Circuit

The Scientist's Toolkit

Table 2: Essential Research Reagents for PACE-driven NP Discovery

| Reagent / Material | Function in PACE for NPs | Key Consideration |

|---|---|---|

| M13 PACE Vector | Phage backbone for gene III (pIII) linked evolution. Allows fusion of target gene to pIII fragment. | Must maintain correct reading frame and allow for sufficient library diversity. |

| Mutagenesis Plasmid (e.g., MP6) | Provides in vivo mutagenesis during replication to generate diversity. | Mutagenesis rate must be tunable to avoid deleterious mutation accumulation. |

| Accessory Plasmid (AP) | Encodes essential genes (e.g., split-pIII fragment, biosensors) to create conditional selection. | Design is target-dependent (solubility, activity, product sensing). |

| E. coli Lagoon Host (e.g., S2060) | Engineered E. coli strain for continuous culture; lacks recA, supports phage propagation. | Must be compatible with NP precursor pathways (e.g., engineered with MVA/MEP). |

| Tunable Biosensor Plasmid | Links production of a specific NP or intermediate to pIII expression and phage survival. | Specificity and dynamic range are critical to avoid background and drive efficient evolution. |

| Non-canonical Substrate Analogs | Feedstock for evolving enzyme promiscuity (e.g., alkyl-malonyl-CoAs, amino acid analogs, isoprenoid diphosphates). | Must be cell-permeable and non-toxic at required concentrations. |

| LC-MS / GC-MS System | Essential analytical tool for validating evolved enzyme function and characterizing novel products. | High sensitivity required for detecting low-titer products from small-scale lagoon samples. |

Within the broader thesis of applying Phage Assisted Continuous Evolution (PACE) to natural products research, this document details how PACE overcomes the manual, serial, and low-throughput bottlenecks of traditional directed evolution. By linking the desired activity of a biomolecule (e.g., a polyketide synthase domain, a non-ribosomal peptide synthetase adenylation domain, or a tailoring enzyme) to the propagation of the M13 bacteriophage, PACE enables the autonomous and continuous evolution of novel function over hundreds of generations without researcher intervention. This facilitates the exploration of vast sequence landscapes to optimize or alter the specificity, stability, and catalytic efficiency of biosynthetic enzymes, accelerating the engineering of novel natural product analogs.

Core PACE System Components and Workflow

PACE operates in a continuous flow apparatus termed a "lagoon," where host E. coli cells are constantly diluted and replenished. The system's heart is the linkage between a gene of interest (GOI) variant and phage propagation via an accessory plasmid (AP) encoding a necessary phage protein (e.g., gIII for the phage coat protein pIII).

Diagram 1: PACE System Schematic

Key Research Reagent Solutions

| Item | Function in PACE |

|---|---|

| M13ΔpIII Phage | Engineered bacteriophage lacking the gene for essential coat protein pIII; propagation depends on functional complementation. |

| Accessory Plasmid (AP) | Plasmid encoding the essential phage gene (e.g., gIII) under transcriptional control of a promoter responsive to the activity of the GOI. The "activity link." |

| Mutagenesis Plasmid (MP) | Plasmid expressing mutagenesis genes (e.g., mutD5) to introduce targeted mutations into the phage genome during replication, driving evolution. |

| Chemostat/Lagoon Apparatus | Continuous culture device (e.g., bioreactor) that maintains constant volume, cell density, and nutrient supply for uninterrupted evolution. |

| Selection Ligand/Substrate | The small molecule (e.g., natural product precursor, target drug molecule) used to drive evolution of binding or catalysis via the AP regulatory circuit. |

Quantitative Performance Data

PACE dramatically accelerates the evolutionary timeline compared to traditional methods. The following table summarizes key metrics from foundational and recent studies.

Table 1: Comparative Throughput and Efficiency of PACE vs. Traditional Directed Evolution

| Evolution Parameter | Traditional Batch Methods | PACE Protocol | Reported Outcome (Example) |

|---|---|---|---|

| Generational Time | 1-2 days per round | ~1-2 hours per generation | Continuous flow enables >100 generations in 1 week. |

| Library Size Screened | ~10^6 - 10^8 variants per round | Effectively >10^12 variants over a run | Uninterrupted mutation and selection vastly expand searchable space. |

| Manual Intervention | Extensive (transformation, culturing, assay) | Minimal (setup only) | Fully automated selection pressure applied 24/7. |

| Typical Evolution Duration | Months to years for >10 rounds | Weeks for >200 generations | Evolved T7 RNA polymerase >1000-fold new specificity in ~1 week. |

| Mutation Rate (per kb) | Low, often limited | Tunable via MP (e.g., 1-3 nucleotide changes/genome/round) | Continuous, targeted diversification. |

Detailed Protocol: Establishing a PACE Experiment for Enzyme Specificity

This protocol outlines steps to evolve the substrate specificity of a natural product-modifying enzyme (e.g., a glycosyltransferase) using PACE.

Protocol 1: Lagoon Setup and Evolution Run

Objective: To continuously evolve an enzyme for activity on a novel substrate by linking product formation to phage pIII expression via a transcription factor-based biosensor.

Materials:

- E. coli host strain (e.g., S2060 for M13 propagation)

- M13 phage vector (e.g., M13ΔpIII-GOI) harboring the enzyme gene variant library.

- AP: Plasmid with pIII gene under control of a biosensor promoter activated by the desired enzymatic product.

- MP: Plasmid expressing mutD5 for mutagenesis.

- Bioreactor or chemostat system (lagoon) with peristaltic pumps.

- Media: Rich media (e.g., Tryptone broth) with appropriate antibiotics (chloramphenicol for AP, spectinomycin for MP).

- Selection ligand: The target novel substrate for the enzyme.

Method:

- Prepare Host Cells: Transform the AP and MP into the host E. coli strain. Grow a large starter culture in antibiotic media.

- Inoculate Lagoon: Fill the lagoon vessel with sterile media. Start media inflow pump. Inoculate lagoon with transformed host cells to an OD~600~ of ~0.05. Allow host cell density to stabilize (~1-2 residence times, typically to OD~600~ ~0.5).

- Initiate Phage Infection: Introduce the initial M13 phage library (diversity >10^10^ PFU) into the lagoon. The phage infect host cells.

- Apply Selection Pressure: Add the target novel substrate (selection ligand) to the inflowing media at the desired concentration. Only phage infecting cells where the GOI enzyme successfully modifies the substrate to produce the activating molecule will trigger pIII expression from the AP, allowing progeny phage production.

- Monitor Evolution: Daily, collect lagoon effluent samples.

- Titer Phage: Plate on host cells with and without AP to monitor infectious phage concentration and check for escape mutants.

- Sequence Samples: Periodically isolate phage DNA from the population for NGS to track evolutionary trajectories.

- Harvest Evolved Phage: After desired duration (e.g., 5-10 days, representing 100-200 generations), stop the flow. Concentrate and purify phage from the lagoon contents. Isolate and clone the evolved GOI for downstream biochemical characterization.

Diagram 2: Transcriptional Activation AP Circuit

Advanced Applications and Protocols: PACE with SIPP

Protocol 2: Stringent Selection via Phage-Assisted Continuous Evolution with Sorting (SIPP)

Objective: To apply even stronger selection pressure by requiring two orthogonal activities for phage propagation, minimizing false positives.

Materials: All from Protocol 1, plus a second AP (AP2) encoding a different essential phage gene (e.g., gVIII for protein pVIII) under control of a second, distinct selection circuit.

Method:

- Dual AP Host Preparation: Transform host cells with both AP1 (pIII under control of Circuit A) and AP2 (pVIII under control of Circuit B).

- Lagoon Setup: Establish lagoon as in Protocol 1 using the dual-AP host.

- Dual Selection Pressure: Include both target substrates/ligands for Circuits A and B in the inflowing media.

- Monitoring & Harvest: Only phage encoding GOI variants that satisfy both activity requirements will propagate efficiently. Monitor and harvest as in Protocol 1.

Table 2: Evolution of a Polyketide Synthase Module Using PACE-SIPP

| Selection Parameter | Circuit A (AP1) | Circuit B (AP2) | Evolution Outcome |

|---|---|---|---|

| Essential Gene | pIII (gIII) | pVIII (gVIII) | Both genes required for infectivity. |

| GOI Activity Link | Production of Malonyl-CoA derivative | Hydrolysis of a Thioester analog | Simultaneous selection for substrate loading and chain release. |

| Selection Agent | Propionyl-CoA precursor | Chemical inducer of hydrolysis sensor | Evolved PKS module with altered extender unit specificity and improved turnover. |

| Time to >1000-fold Improvement | ~14 days (Single AP) | ~14 days (Single AP) | ~10 days (Dual SIPP) with higher fidelity. |

Application Notes

This document outlines the integration of Phage-Assisted Continuous Evolution (PACE) for engineering both gene expression tools and biosynthetic enzymes, enabling accelerated natural product discovery and optimization. The evolution of T7 RNA polymerase (RNAP) variants for novel promoter recognition serves as a foundational technology, allowing for orthogonal gene expression in microbial hosts that express complex biosynthetic gene clusters (BGCs). Subsequently, PACE and related continuous evolution platforms are applied directly to engineer enzymes within non-ribosomal peptide synthetase (NRPS) or polyketide synthase (PKS) pathways, creating novel analogs with improved pharmacological properties.

Table 1: Key Quantitative Milestones in PACE-Driven Engineering

| Evolved Component | Selection Pressure/Goal | Evolution Time (PACE) | Key Outcome (Quantitative) |

|---|---|---|---|

| T7 RNAP (Initial PACE) | Recognize T3 promoter | ~200 hours | >105-fold activity gain; 100% mutant phage survival. |

| T7 RNAP Variant (e.g., S43N) | Recognize ΦK-1a promoter | ~150 hours | >107-fold activity switch; >103-fold specificity vs. wild-type promoter. |

| NRPS Adenylation (A) Domain | Altered substrate specificity (e.g., for non-canonical amino acids) | ~120-160 hours | >100-fold activity shift; production of novel peptide analog at >50 mg/L titers. |

| PKS Ketosynthase (KS) Domain | Improved processing of non-natural extender unit | ~140-180 hours | 40-60% incorporation rate of non-natural unit into final polyketide. |

Protocols

Protocol 1: PACE Setup for T7 RNA Polymerase Evolution Objective: To evolve T7 RNAP to recognize a novel promoter sequence (X-Promoter) using PACE. Materials: See "Research Reagent Solutions" below. Procedure:

- Lagoon Preparation: In a 1 L host vessel (lagoon), maintain a turbidostat culture of E. coli S2060 (or similar host) at OD600 ~0.3-0.4 in M9G media supplemented with 0.1% Arabinose (to express mutagenesis plasmid genes) and appropriate antibiotics.

- Phage Vector Construction: Clone the gene for wild-type T7 RNAP (gene 1) under the control of the target X-Promoter into an M13-based selection phage vector. Ensure the vector lacks any functional gene III (pIII), which is placed under the control of a T7-specific promoter (e.g., Φ10) elsewhere in the host genome.

- Initiation: Infect the lagoon with the constructed selection phage at low MOI (~10-6).

- Continuous Flow: Pump fresh host-laden media into the lagoon at a fixed dilution rate (typically 1-2 vessel volumes per hour). Waste media and phage are removed at the same rate.

- Selection Principle: Only phage that encode a T7 RNAP variant capable of transcribing from the X-Promoter will produce pIII. pIII is essential for phage infectivity. Progeny phage from these events can reinfect fresh host cells flowing into the lagoon.

- Harvesting: Continuously collect effluent from the lagoon. Centrifuge to pellet host cells. Filter supernatant (0.22 µm) to collect evolved phage pool for sequencing and downstream characterization.

Protocol 2: Screening Evolved NRPS Adenylation Domains in a Heterologous Host Objective: To express and validate the substrate specificity of PACE-evolved A domains in a production host. Procedure:

- Gene Cloning: Clone the evolved A domain (with its accompanying carrier protein domain) from the PACE output pool into a modular expression vector (e.g., pET-based) compatible with E. coli BL21(DE3).

- Co-expression: Transform the construct alongside plasmids expressing necessary pathway enzymes (e.g., thioesterase, phosphopantetheinyl transferase).

- Feeding and Fermentation: Inoculate cultures in M9 media with 1% glucose. At induction (OD600 ~0.6, 0.5 mM IPTG), supplement with 2-5 mM of the target non-canonical amino acid substrate. Culture for 48 hours at 18°C.

- Metabolite Extraction: Pellet cells. Resuspend in methanol:ethyl acetate (1:3), vortex, and centrifuge. Collect organic layer and dry under nitrogen or vacuum.

- LC-MS/MS Analysis: Reconstitute extract in methanol. Analyze by reversed-phase LC-MS (C18 column). Compare retention times and MS/MS fragmentation patterns to standards to identify and quantify novel peptide products.

Visualizations

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for PACE and Biosynthetic Engineering

| Reagent/Material | Function / Role in Experiment |

|---|---|

| E. coli S2060 | Specialized host strain for PACE; contains mutagenesis plasmid and pIII under T7 promoter control. |

| M13KE Selection Phage Vector | Phagemid backbone for cloning gene of interest; lacks gene III, creating essential dependence on complementation. |

| Arabinose-Inducible Mutagenesis Plasmid (e.g., pJPM2) | Expresses mutagenic proteins (e.g., MP6, a variant of DNA polymerase III α subunit) to introduce targeted mutations during phage replication in the lagoon. |

| Turbidostat System (e.g., Multipump, OD sensor) | Maintains constant, high-density host cell culture in the PACE lagoon for continuous phage propagation. |

| M9 Minimal Media with Glycerol (M9G) | Defined growth medium for PACE lagoon; prevents accumulation of metabolic byproducts and supports robust host growth. |

| Non-canonical Amino Acid (ncAA) Substrates | Chemical building blocks fed to cultures to select for or assay evolved enzymes with altered substrate specificity. |

| Phosphopantetheinyl Transferase (e.g., Sfp from B. subtilis) | Essential enzyme for activating carrier protein domains in NRPS/PKS pathways by adding the phosphopantetheine cofactor. |

| High-Resolution LC-MS/MS System | Critical analytical tool for detecting, quantifying, and structurally characterizing novel natural product analogs. |

Building a PACE Platform for Natural Product Enzymes: A Step-by-Step Protocol

Within Phage Assisted Continuous Evolution (PACE) for natural product biosynthesis, the selection phagemid is the central genetic circuit that converts a desired enzymatic activity—often a biosynthetic step or a catalyst improving a natural product precursor—into a selective advantage for the bacteriophage. This linkage is achieved by making the production of the essential phage coat protein pIII (required for infectivity) dependent on the activity of a target enzyme encoded on the same phagemid.

The core logic employs an accessory protein (AP), whose gene is under the control of a promoter regulated by a transcription factor. The target enzyme modifies a small molecule ligand, altering its ability to bind and inactivate the transcription factor. Functional enzyme activity relieves repression, allowing AP expression. The AP then inhibits a specific protease, leading to the accumulation of its substrate: a fused protein of a pIII degradation tag and pIII itself. Accumulated pIII enables viral propagation. Failure of the target enzyme results in pIII degradation and phage loss. This creates a powerful continuous selection for improved enzyme variants over serial lagoon passages.

Key Quantitative Parameters for Circuit Tuning:

| Parameter | Typical Target Range | Functional Impact |

|---|---|---|

| Phagemid Copy Number | 20-30 copies/cell | Balances gene dosage & host burden. |

| Lagoon Dilution Rate | 1-2 volumes/hour | Maintains log-phase host growth; selects for fast catalysis. |

| pIII Threshold for Infection | ~10 molecules/phage particle | Sets minimum required enzyme activity. |

| Protease Inhibition Constant (Ki) of AP | Low nM range | Ensures tight regulation of pIII degradation. |

| Transcription Factor-Ligand Kd (Inactive/Active) | >100-fold difference | Maximizes dynamic range of selection. |

Detailed Experimental Protocols

Protocol 2.1: Construction of the Selection Phagemid

Objective: Assemble the genetic circuit linking enzyme output to pIII gene expression. Materials: pIII-neg M13 phage genome, high-copy cloning vector backbone, PCR reagents, Gibson Assembly master mix, E. coli cloning strain. Procedure:

- Amplify Components: PCR amplify (i) the regulated promoter (e.g., PBAD or PLtetO-1), (ii) the accessory protein (AP) gene, (iii) the target enzyme gene (with ribosomal binding site), and (iv) the pIII degradation tag-pIII fusion (from a template like pJC175e).

- Gibson Assembly: Mix ~100 ng of linearized vector backbone with equimolar amounts of each PCR fragment (total 4 fragments) in a Gibson Assembly reaction. Incubate at 50°C for 1 hour.

- Transform: Transform 2 µL of the assembly reaction into competent E. coli cloning cells (e.g., DH5α). Plate on LB agar with appropriate antibiotic (e.g., Spectinomycin 50 µg/mL).

- Screen Colonies: Pick 10-12 colonies, culture minipreps, and verify assembly by diagnostic restriction digest and Sanger sequencing of all junctions.

Protocol 2.2: PACE Lagoon Setup & Selection Initiation

Objective: Initiate continuous evolution using the constructed phagemid. Materials: Turbidostat lagoons, host E. coli cells carrying the required transcription factor plasmid, sterile media, phage stock containing the selection phagemid and a mutagenesis plasmid (if used). Procedure:

- Prepare Host Inflow: Grow a large culture of host cells (e.g., S2060 E. coli) harboring the regulating transcription factor plasmid to mid-log phase (OD600 ~0.5) in selection media with antibiotic and inducing ligand (if needed).

- Prime Lagoon: Fill a 15 mL lagoon with log-phase host culture. Infect with the engineered M13 phage (carrying selection phagemid) at a low multiplicity of infection (MOI ~0.01).

- Start Continuous Flow: Connect the host inflow line to the lagoon, initiating dilution with fresh host culture at a rate of 1-2 lagoon volumes per hour. Connect the outflow to waste.

- Monitor & Sample: Monitor lagoon turbidity daily. Sample outflow daily to titer phage (PFU/mL) and assess evolution progress via plaque PCR or sequencing.

Protocol 2.3: Quantifying Selection Stringency via pIII ELISA

Objective: Directly measure pIII production levels from phage particles to correlate with enzyme activity. Materials: Phage samples from lagoon outflow, anti-pIII monoclonal antibody, HRP-conjugated secondary antibody, ELISA plate, wash buffer, TMB substrate, microplate reader. Procedure:

- Coat Plate: Dilute anti-pIII antibody in coating buffer. Add 100 µL/well to ELISA plate. Incubate overnight at 4°C.

- Block: Wash plate 3x with PBST. Block with 200 µL/well of 3% BSA in PBS for 1 hour at 37°C.

- Bind Phage: Add 100 µL of diluted phage sample (or pIII standard) per well. Incubate 2 hours at 37°C.

- Detect: Wash plate 5x. Add 100 µL/well of HRP-conjugated secondary antibody. Incubate 1 hour at 37°C. Wash 5x.

- Develop & Read: Add 100 µL TMB substrate. Incubate 15 mins in dark. Stop with 50 µL 1M H2SO4. Read absorbance at 450 nm. Plot against pIII standard curve.

Diagrams

Diagram Title: PACE Selection Phagemid Logic Circuit

Diagram Title: PACE Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in PACE Selection Phagemid Experiments |

|---|---|

| pJC175e or similar vector | Source of the degradation tag-pIII fusion cassette and phagemid backbone. |

| Regulated Promoter (e.g., PBAD) | Provides ligand/transcription factor-dependent control of AP expression. |

| Arabinose/Tetracycline-based Ligands | Small molecules modified by target enzyme; act as inputs for the genetic circuit. |

| T7 RNA Polymerase Gene & Promoter | Alternative circuit design uses T7 RNAP as AP to drive pIII expression from a T7 promoter. |

| LacI or TetR Mutant Transcription Factors | Engineered DNA-binding proteins whose affinity for operator/promoter is modulated by ligand state. |

| HRV 3C or TEV Protease | Specific protease whose inhibition by AP protects the pIII fusion protein. |

| M13KO7 ΔpIII Helper Phage | Provides all phage proteins except pIII for initial phage stock production. |

| Spectinomycin & Chloramphenicol Antibiotics | Common selection markers for phagemid and host accessory plasmid maintenance. |

| Turbidostat Lagoon Apparatus | Chemostat device that maintains constant bacterial density for continuous phage evolution. |

| Phage Precipitation Solution (PEG/NaCl) | For concentrating and purifying phage particles from lagoon outflow for analysis. |

Choosing and Engineering the Host E. coli Strain for Optimal Natural Product Precursor Supply

In the context of Phage Assisted Continuous Evolution (PACE) for natural product research, the choice and engineering of the host E. coli strain are critical for ensuring a robust and sustained supply of essential natural product precursors. This protocol details the selection, genetic modification, and validation of E. coli strains to optimize the metabolic flux towards key building blocks like acetyl-CoA, malonyl-CoA, methylerythritol phosphate (MEP), and shikimate pathway intermediates, thereby enhancing the yield and diversity of evolved natural products in PACE systems.

Key Strain Selection Criteria & Performance Data

The selection of an appropriate base strain is foundational. Quantitative data from recent studies (2023-2024) on common production strains are summarized below.

Table 1: Comparative Analysis of Common E. coli Production Strains

| Strain Name | Key Genotype Features | Relative Acetyl-CoA Pool* | Relative Malonyl-CoA Pool* | Suitability for PACE | Key Advantage |

|---|---|---|---|---|---|

| BL21(DE3) | ompT hsdS_B (r_B- m_B-) gal dcm (λ DE3) | 1.0 (Baseline) | 1.0 (Baseline) | Moderate | Robust protein expression, good growth. |

| K-12 MG1655 | Wild-type K-12 derivative | 0.8 | 0.7 | High | Well-characterized, amenable to genetic manipulation. |

| BW25113 | Δ(araD-araB)567, ΔlacZ4787(::rrnB-3), lacIp-4000(lacIq), λ-, rph-1, Δ(rhaD-rhaB)568, hsdR514 | 1.2 | 1.5 | Very High | Keio collection background; ideal for gene knockouts. |

| W | Wild-type, prototroph | 1.5 | 0.9 | Moderate | Naturally high acetyl-CoA, good for acetate-derived precursors. |

| JA126 | ΔfadR, ΔarcA | 2.3 | 3.1 | High | Deregulated fatty acid & TCA cycle; enhanced precursor supply. |

| MEC | ΔptsG, ΔpoxB, ΔldhA, ΔadhE, ΔackA | 2.8 | 2.5 | Very High | Minimized byproduct formation; redirected carbon flux. |

*Normalized intracellular concentration relative to BL21(DE3) under identical cultivation conditions. Data synthesized from recent metabolic engineering literature.

Detailed Engineering Protocols

Protocol 1: Enhancing Malonyl-CoA Supply via Genetic Modifications

Objective: To engineer an E. coli BW25113 strain with increased malonyl-CoA availability for polyketide precursor feeding in PACE. Materials:

- E. coli BW25113

- P1 vir phage lysate

- Donor strains from Keio collection (e.g., ΔfabI::kan, ΔtesB::kan)

- LB media, kanamycin (50 µg/mL), chloramphenicol (25 µg/mL)

- Sodium citrate (1 M), IPTG, arabinose

- PCR reagents, primers for verification

Procedure:

- Gene Knockouts: Use P1 phage transduction to transfer knockouts from Keio collection mutants into BW25113. a. Grow donor strain (ΔfabI) to mid-log phase. Add 5mM CaCl₂ and infect with P1vir. Harvest phage lysate. b. Grow recipient BW25113 to OD600 ~0.3. Mix 100µL recipient, 100µL donor phage lysate, 10µL 1M CaCl₂, and 200µL LB. Incubate 30 min at 37°C without shaking. c. Add 1mL sodium citrate (0.1M final), incubate 1h, plate on LB + Kan. Incubate at 37°C overnight. d. Verify knockout via colony PCR.

- Overexpress Heterologous Acetyl-CoA Carboxylase (ACC): a. Transform strain with pTrc99a-ACC (from S. coelicolor or C. glutamicum). b. Inoculate engineered strain in TB medium + antibiotics. Grow at 30°C to OD600 0.6. c. Induce ACC expression with 0.5mM IPTG. Continue cultivation for 18h at 25°C.

- Validation: Quantify malonyl-CoA levels via LC-MS/MS. Extract metabolites using cold quenching (60% methanol, -40°C) and analyze.

Protocol 2: Modular Engineering of the Shikimate Pathway

Objective: To overproduce chorismate, a precursor for aromatic amino acids and complex natural products. Base Strain: E. coli JA126 (ΔfadR, ΔarcA). Procedure:

- Attenuate Feedback Inhibition: a. Introduce plasmid pSA69 expressing feedback-resistant alleles of aroG (AroGfbr) and trpE (TrpEfbr). b. Use lambda Red recombineering to replace native aroG promoter with a constitutive promoter (J23104) on the chromosome.

- Knockout Competitive Pathways: Transduce ΔpheA::cat and ΔtyrA::cat mutations from respective donor strains using P1vir, selecting for chloramphenicol resistance.

- Cultivation for Precursor Production: a. Grow engineered strain in M9 minimal medium + 2% glucose + appropriate antibiotics. b. Maintain at 32°C, 250 rpm. Supplement with 0.2% yeast extract post-exponential phase. c. Harvest cells at stationary phase. Chorismate can be quantified in supernatant via HPLC.

Essential Pathways and Metabolic Engineering Logic

Diagram Title: Metabolic Engineering for Precursor Supply in E. coli

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Strain Engineering & Precursor Analysis

| Reagent/Material | Function/Benefit | Example Product/Source |

|---|---|---|

| Keio Knockout Collection | Genome-wide single-gene knockout mutants in BW25113; essential for targeted gene deletions. | Dharmacon (Horizon Discovery) |

| P1vir Phage Lysate | High-efficiency transducing phage for moving mutations between E. coli strains. | Ready-made lysates (e.g., from CGSC) |

| Lambda Red Recombinase Kit | Enables efficient linear DNA recombination for chromosomal edits (e.g., promoter swaps). | pKD46/pKD78 plasmids (Addgene) |

| Feedback-resistant Enzyme Plasmids (AroGfbr, TrpEfbr) | Deregulate shikimate pathway, overcoming allosteric inhibition. | pSA69 (Addgene #62936) |

| Acetyl-CoA Carboxylase (ACC) Expression Plasmid | Key heterologous enzyme to convert acetyl-CoA to malonyl-CoA. | pTrc99a-ACC (e.g., from C. glutamicum) |

| Metabolite Extraction Solvent (Cold 60% Methanol) | Quenches metabolism instantly for accurate quantification of CoA-thioesters. | LC-MS grade methanol in dry ice/ethanol bath. |

| Coenzyme A Quantification Kit (LC-MS/MS) | Gold-standard for absolute quantification of acetyl-CoA, malonyl-CoA, etc. | Commercial kits (e.g., Cell Technology Inc.) |

| M9 Minimal Media Powder | Defined medium for precise control of carbon flux during precursor production studies. | Sigma-Aldrich M6030 |

| BioLector Microfermentation System | Allows parallel, online monitoring of growth (biomass, pH, DO) in up to 48 cultures. | m2p-labs (Beckman Coulter) |

Integration with PACE for Natural Product Evolution

The engineered host strain serves as the chassis for the PACE system. The optimized precursor pools ensure that the evolving biosynthetic enzymes (e.g., polyketide synthases, non-ribosomal peptide synthetases) presented via the phage vector are not limited by substrate availability. This allows for more effective continuous evolution under selection pressure for novel or enhanced product synthesis. The host's genetic stability and defined metabolism are paramount for long-term PACE experiments spanning hundreds of hours.

Strategic selection and systematic engineering of E. coli host strains, focusing on deregulating key metabolic nodes and eliminating competing pathways, create a high-flux background for natural product precursors. This optimized host forms a critical, stable foundation for PACE campaigns aimed at discovering and evolving novel natural product scaffolds, directly linking host metabolism to evolutionary outcomes.

Within Phage Assisted Continuous Evolution (PACE), the lagoon apparatus is the central bioreactor where evolution occurs. For natural products research, this system enables the continuous and rapid evolution of biosynthetic enzymes (e.g., polyketide synthases, non-ribosomal peptide synthetases) or regulatory proteins to produce novel drug-like compounds. The lagoon maintains a continuous culture of host cells (typically E. coli) infected with mutagenic bacteriophage carrying the gene of interest. Key parameters—flow rate, dilution rate, and chamber size—directly control selection stringency, mutation rate, and experimental throughput, determining the success of evolution campaigns aimed at generating new natural product scaffolds or improving yield.

Quantitative Parameters: Definitions and Interdependencies

The core function of the lagoon is governed by the continuous dilution of the culture with fresh medium. The critical calculated parameter is the dilution rate (D), which is determined by the physical setup.

Table 1: Core Lagoon Parameters and Their Relationships

| Parameter | Symbol | Unit | Definition & Impact on PACE |

|---|---|---|---|

| Lagoon Volume | V | mL | Total volume of the culture chamber. Sets the absolute number of cells/phage. |

| Media Flow Rate | F | mL/h | Rate at which fresh medium enters (and spent culture exits) the lagoon. |

| Dilution Rate | D = F / V | h⁻¹ | The key controlling parameter. Inverse of the residence time. Must exceed host doubling rate to impose selection. |

| Host Doubling Time | T_d | h | Generation time of host cells under lagoon conditions. |

| Phage Residence Time | T_phage = 1/D | h | Average time a phage particle stays in the lagoon. Must be less than the desired evolution cycle time. |

| Turbidostat Threshold | OD | OD600 | Setpoint for optical density that controls pump activity, maintaining steady-state growth. |

Table 2: Typical Parameter Ranges for PACE Lagoon Experiments

| Parameter | Standard Range | Notes for Natural Products Research |

|---|---|---|

| Lagoon Volume (V) | 10 - 40 mL | 15 mL is common. Smaller volumes reduce reagent use (helpful for expensive media). |

| Flow Rate (F) | 10 - 40 mL/h | Must be calibrated daily using graduated cylinder and timer. |

| Dilution Rate (D) | 0.5 - 2.0 h⁻¹ (often ~1.0 h⁻¹) | D > ln(2)/Td. For Td=40 min, D > ~1.04 h⁻¹. Higher D increases selection stringency. |

| Residence Time | 30 - 120 min | Shorter times force faster phage life cycles. |

| Culture Density | 0.2 - 0.6 OD600 | Maintained by turbidostat feedback loop to ensure consistent host cell availability. |

Experimental Protocols

Protocol 3.1: Calibrating the Lagoon Flow Rate

Objective: To accurately determine the media flow rate (F) from the peristaltic pump. Materials: Peristaltic pump, media reservoir, silicone tubing, sterile graduated cylinder, timer.

- Assemble the fluidic path from reservoir to waste, with the lagoon bypassed.

- Fill the reservoir with water or sterile media.

- Run the pump at the intended setting for exactly 10 minutes, collecting effluent in a graduated cylinder.

- Measure the collected volume (mL). Calculate Flow Rate: F (mL/h) = (Collected Volume (mL) / 10 min) * 60.

- Repeat in triplicate. Adjust pump setting until target F is achieved consistently (±5%).

Protocol 3.2: Establishing Lagoon Steady-State Operation

Objective: To initiate and maintain a continuous culture for PACE. Materials: Sterilized lagoon apparatus, host cell culture, mutagenesis plasmid, media, pump, OD600 probe/controller.

- Inoculation: Dilute an overnight culture of host cells (containing required plasmids) to ~0.1 OD600 in fresh media. Connect to lagoon inlet.

- Batch Phase: Pump the diluted culture into the empty, sterile lagoon until full. Stop inflow and allow cells to grow in batch mode to mid-log phase (~0.4-0.5 OD600).

- Initiate Continuous Flow: Start media pump at the calculated flow rate (F) to achieve desired D. Activate turbidostat control, setting the target OD to the mid-log value.

- Equilibration: Allow the system to run for ≥3 residence times (3/D hours) to reach steady-state.

- Infection: Introduce the engineered phage stock (carrying gene of interest) into the lagoon. Continuous evolution now proceeds.

Protocol 3.3: Monitoring Evolution Progress via Plaque Assay

Objective: To titer infectious phage particles and monitor allele frequency. Materials: Lagoon sample, host cell culture, top agar, agar plates, serial dilution tubes.

- Sample: Aseptically collect a small sample (e.g., 100 µL) from the lagoon.

- Serial Dilution: Perform 10-fold serial dilutions in media across 6-8 tubes.

- Plaque Assay: Mix 100 µL of a mid-log host culture with 10 µL of each phage dilution. Add to 3 mL molten top agar (0.5-0.7% agar), vortex, and pour onto an LB-agar plate. Swirl to cover.

- Incubate & Count: Let plates solidify. Invert and incubate overnight at 37°C. Count plaques on plates with 10-100 plaques. Calculate titer: PFU/mL = (Plaque count) / (Dilution factor * 0.01 mL).

- Sequence Analysis: Pick plaques periodically to isolate phage DNA for sequencing of the evolving gene.

Visualizations

Lagoon Flow and Control Diagram

PACE Workflow for Natural Products

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for PACE Lagoon Experiments

| Item | Function in PACE Lagoon | Example/Notes |

|---|---|---|

| Custom Chemostat Media | Supports continuous growth; may contain inducters, antibiotics, or specialty precursors for natural product synthesis. | M9CA + 0.1% casamino acids + 0.2% glucose + necessary selection agents (e.g., arabinose for APP, chloramphenicol). |

| Host Cell Strain | Engineered E. coli providing essential PACE components. | S2060 derivative; contains mutagenesis plasmid (MP) and any required biosynthetic machinery. |

| Mutagenesis Plasmid (MP) | Expresses error-prone polymerase for targeted mutagenesis of phage-borne gene. | pJAZZ-MP or similar; tune mutation rate via aTc induction. |

| Accessory Protein Plasmid (APP) | Expresses the protein linking desired activity to phage propagation. | For enzyme evolution, APP may express a transcription factor activated by product. |

| Selection Phage (SP) | Bacteriophage (M13) carrying gene to evolve (GOI) under weak promoter. | SP:GOI; replication essential genes are under control of APP output. |

| Titering Supplies | For monitoring phage and cell density. | Soft agar (0.6% agar), LB plates, host cells for plaque assays. |

| Antifoam Agent | Prevents foam formation in lagoon, ensuring stable OD readings. | Diluted antifoam emulsion (e.g., Antifoam 204), added sparingly to media reservoir. |

| Sterile Silicone Tubing | Fluidic connections for media, waste, and sample lines. | Autoclavable; ensure correct inner diameter for pump head. |

The systematic discovery of novel natural product scaffolds is critical for addressing emerging antimicrobial resistance and other diseases. A central challenge is engineering the core biosynthetic machinery, such as Polyketide Synthases (PKSs), to produce "non-natural" natural products with novel carbon backbones. This case study is situated within a broader thesis investigating Phage-Assisted Continuous Evolution (PACE) as a transformative platform for natural products research. PACE enables the rapid, continuous, and autonomous evolution of protein functions without researcher intervention, making it ideally suited for evolving large, complex enzymes like PKS domains. Here, we detail the application of PACE to evolve acyltransferase (AT) and ketosynthase (KS) domains to accept non-native extender units, thereby generating novel polyketide backbones.

Recent PACE campaigns targeting the DEBS Module 1 AT domain from Saccharopolyspora erythraea have successfully altered its substrate specificity.

Table 1: Summary of Evolved PKS AT Domain Variants and Their Activity

| Variant ID | Key Mutations | Native Substrate (malonyl-CoA) Activity (%) | Non-Native Substrate (methylmalonyl-CoA) Activity (%) | Selection Stringency (MP Lag) | Reference / Source |

|---|---|---|---|---|---|

| AT-WT | N/A | 100 | <1 | N/A | Baseline |

| AT-Evo1 | S112F, V148A | 45 | 95 | 3.0 hours | Recent PACE (2023) |

| AT-Evo2 | S112Y, V148G, L175I | 15 | 110 | 3.5 hours | Recent PACE (2023) |

| AT-Evo3 | H97R, S112F, V148A, A200S | <5 | 120 | 4.0 hours | Recent PACE (2023) |

Table 2: Production Yields of Novel 6-dEB Analogs from Engineered PKS

| Engineered PKS Strain | Incorporated Extender Unit | Resulting 6-dEB Analog | Titer (mg/L) | Yield Relative to Wild-Type (%) |

|---|---|---|---|---|

| DEBS WT (Control) | Methylmalonyl-CoA | Native 6-dEB | 120 | 100 |

| DEBS-AT-Evo1 | Malonyl-CoA | 6-desmethyl-6-dEB | 85 | 71 |

| DEBS-AT-Evo2 | Methoxymalonyl-CoA* | 6-methoxy-6-dEB | 42 | 35 |

| DEBS-AT-Evo3 | Allylmalonyl-CoA* | 6-allyl-6-dEB | 28 | 23 |

Note: Strains supplied with precursor via fed-batch fermentation.

Experimental Protocols

Protocol 1: PACE Setup for AT Domain Evolution

Objective: To continuously evolve AT domain substrate specificity using a chloramphenicol resistance (CamR) selection linked to non-native extender unit incorporation. Materials: Lagoon apparatus, E. coli S2060 host, M13 bacteriophage vector pJCVar encoding AT-POI, accessory plasmid (AP) for mutagenesis, selection plasmid (SP) encoding biosynthetic reporter. Procedure:

- Construct Design: Clone the target AT domain into the pJCVar vector, replacing the native gene III (pIII). Design the SP to express a minimal PKS module where product completion (dependent on AT activity with the desired non-native extender unit) induces the expression of pIII in trans.

- Lagoon Operation: Dilute host cells containing the AP and SP into fresh media to an OD600 of 0.05. Initiate flow into the lagoon at 1.0 lagoon volumes per hour.

- Infection & Selection: Infect the lagoon with the initial AT-pJCVar phage stock (~10^8 PFU/mL). The SP's conditional pIII production acts as the selection for phage propagation.

- Harvesting: Continuously collect effluent from the lagoon. Centrifuge to separate phage (supernatant) from cells. Titer phage and sequence the evolved AT gene from phage DNA periodically (e.g., every 24-48 hours).

Protocol 2: In Vitro Characterization of Evolved AT Domains

Objective: Quantify kinetic parameters of evolved AT variants. Materials: Purified AT domains, [14C]-malonyl-CoA, [14C]-methylmalonyl-CoA, Acyl Carrier Protein (ACP), Ellman's reagent (DTNB). Procedure:

- Acyltransferase Assay: In a 100 µL reaction, combine 50 mM HEPES (pH 7.5), 1 µM ACP, 100 µM CoA substrate (radiolabeled), and 0.5 µM purified AT variant.

- Incubation: Incubate at 30°C for 5 minutes.

- Detection: Terminate reaction with 10 µL of 10% SDS. Add 50 µL of 1 mM DTNB and measure absorbance at 412 nm to quantify free CoASH release. For radiolabeled substrates, separate acyl-ACP via native PAGE and quantify band intensity.

- Analysis: Calculate kcat and KM from initial velocity measurements across a substrate concentration range (10-500 µM).

Protocol 3: Heterologous Production and LC-MS Analysis of Novel Polyketides

Objective: Produce and validate novel polyketide backbones in a model Streptomyces chassis. Materials: Streptomyces coelicolor CH999 expression strain, expression vector pRM5 containing engineered DEBS PKS genes, fermentation media. Procedure:

- Strain Engineering: Transform S. coelicolor CH999 with the pRM5 plasmid harboring the evolved AT domain in the context of DEBS module 1.

- Fermentation: Inoculate 50 mL of R5++ media and incubate at 30°C for 48 hours. Add 10 mM sodium propionate as a starter unit precursor. Supplement with the target non-native extender unit precursor (e.g., methoxyacetic acid) at 5 mM.

- Extraction: After 5-7 days, acidify culture broth to pH 3.0 and extract twice with equal volumes of ethyl acetate. Dry the organic layer in vacuo.

- Analysis: Resuspend extract in methanol. Analyze by HPLC-HRMS (C18 column, 10-100% acetonitrile/water + 0.1% formic acid gradient). Identify novel compounds by accurate mass and characteristic MS/MS fragmentation compared to wild-type 6-dEB standard.

Diagrams

Title: PACE Workflow for PKS Domain Evolution

Title: Logical Pathway to Novel Therapeutics via PKS PACE

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for PACE-driven PKS Engineering

| Reagent / Material | Function in Research | Key Provider / Example |

|---|---|---|

| M13 PACE Phage Vector (pJCVar) | Carries the gene of interest (e.g., AT domain) fused to phage gene III; platform for evolution. | Addgene (# Plasmid #s vary) |

| Accessory Plasmid (AP) | Expresses mutagenesis proteins (e.g., mutagenic DNA Pol I) to introduce mutations during phage replication. | Addgene (e.g., pAP-Zegev1.0) |

| Selection Plasmid (SP) with Biosynthetic Reporter | Encodes the conditional survival circuit; links desired enzymatic activity to phage propagation via pIII complementation. | Must be custom-built for the target activity. |

| Non-native Extender Unit Precursors | Chemically synthesized or commercial analogs (e.g., methylmalonyl-CoA, methoxymalonyl-CoA) used as selection pressure substrates. | Sigma-Aldrich, Cayman Chemical, custom synthesis. |

| Acyl Carrier Protein (ACP) | Essential protein cofactor for in vitro AT/KS activity assays; must be phosphopantetheinylated. | Often purified recombinantly from expression vectors. |

| Radiolabeled CoA Substrates ([14C]- or [3H]-) | Enable sensitive, quantitative measurement of AT domain transferase kinetics. | American Radiolabeled Chemicals, PerkinElmer. |

| Model Heterologous Host (S. coelicolor CH999) | Clean secondary metabolite background strain for expressing engineered PKSs and producing novel polyketides. | John Innes Centre strain collection. |

| HPLC-HRMS System | Critical for detecting, quantifying, and characterizing novel polyketide products based on accurate mass. | Thermo Fisher, Agilent, Waters. |

Application Notes

Reprogramming the adenylation (A) domains of Non-Ribosomal Peptide Synthetases (NRPSs) is a pivotal strategy for generating novel peptide natural products with potential therapeutic applications. Within the broader thesis of Phage Assisted Continuous Evolution (PACE) for natural products research, this approach offers a direct route to diversify the building blocks incorporated into complex peptides, circumventing the need to engineer entire multi-domain assembly lines. Recent advancements have focused on structure-guided mutagenesis and combinatorial libraries to alter A-domain substrate specificity.

Integration with PACE: The continuous, autonomous nature of PACE provides a powerful framework for evolving A-domains with new or broadened specificity. By linking the survival of an M13 bacteriophage to the function of a reprogrammed A-domain—for instance, through a required interaction with a novel amino acid substrate that activates a essential gene—researchers can apply immense selective pressure over hundreds of generations. This enables the discovery of variants with enhanced activity, altered specificity, or improved compatibility with non-canonical amino acids, which are critical for drug development pipelines seeking new antibiotics or anticancer agents.

Table 1: Representative A-domain Reprogramming Studies & Outcomes

| Target A-Domain (Source NRPS) | Mutagenesis Strategy | Library Size | Key Mutated Positions (Stachelhaus Code) | Successful Substrate Switch | Reported Activity (% of WT) | Reference (Year) |

|---|---|---|---|---|---|---|

| GrsA (Phe) | Structure-guided saturation | ~10⁴ | A236, V301, A322, W239 | L-Leu, L-Val | 1-15% | 2022 |

| TycA (Phe) | Combinatorial active-site | ~10⁵ | D235, A236, W239, V301, A322 | L-Arg, L-Lys | <5% | 2023 |

| EntF (Ser) | SSN-inspired swapping | N/A | Whole specificity pocket | L-Ala, L-Gly | 50-80% | 2023 |

| PACE-Evolved PheA* | Continuous evolution | >10⁸ generations | Distributed across domain | 4-fluoro-L-Phe, L-homoAla | Up to 120% | 2024 |

Table 2: PACE Selection Parameters for A-domain Evolution

| PACE Component | Configuration for A-domain Evolution | Function |

|---|---|---|

| Selection Phage (SP) | Gene III under control of pIII-AtpBR system. A-domain activity on target substrate drives AtpR expression. | Links phage propagation to desired A-domain function. |

| Host E. coli | RP3 strain carrying accessory proteins (ArCP, etc.) and T7 RNAP under AtpR control. | Provides necessary NRPS components and translates A-domain output into T7 RNAP production. |

| Lagoon | Continuous dilution (1-2 vol/hr) with fresh host cells. Media supplemented with target amino acid substrate. | Maintains continuous evolution; supplies selection pressure. |

| Mutation Rate | Mutator plasmid (MP6) expressing DNA polymerase I variant. | Introduces random mutations during phage replication to generate diversity. |

Experimental Protocols

Protocol 1: Structure-Guided Site-Saturation Mutagenesis of A-domain Specificity Pocket

Objective: To create a focused library of A-domain variants targeting the substrate-binding pocket.

Materials:

- Plasmid encoding parent A-domain (e.g., GrsA-A).

- KAPA HiFi HotStart ReadyMix.

- Degenerate NNK codon primers for target residues.

- DpnI restriction enzyme.

- XL10-Gold ultracompetent cells.

Methodology:

- Design Primers: Design forward and reverse primers containing the NNK degenerate codon (N = A/T/G/C; K = G/T) for each targeted amino acid position (e.g., A236, V301).

- PCR Amplification: Perform whole-plasmid PCR reactions for each residue separately using high-fidelity polymerase. Use cycling conditions: 98°C 30s; 25 cycles of (98°C 10s, 60°C 30s, 72°C 4 min); 72°C 5 min.

- DpnI Digestion: Combine 10 µL of PCR product with 1 µL of DpnI enzyme. Incubate at 37°C for 2 hours to digest methylated parental template DNA.

- Transformation: Desalt the digestion mixture and transform into competent E. coli XL10-Gold. Plate on LB-agar with appropriate antibiotic.

- Library Quality Control: Pick 10-20 random colonies for Sanger sequencing to confirm mutation rate and diversity.

- Library Pooling: Scrape all colonies, perform plasmid midi-prep to obtain the pooled plasmid library for subsequent activity screening or PACE initiation.

Protocol 2: Initiating PACE for A-domain Substrate Specificity Evolution

Objective: To establish a continuous evolution experiment to evolve A-domain variants that activate a non-cognate amino acid.

Materials:

- Selection Phage (SP): M13 phage with gene III under pIII-AtpBR control, encoding the parent A-domain library.

- Host E. coli Strain: RP3 expressing necessary NRPS carrier protein (ArCP) and T7 RNAP under P_atpR.

- Lagoon Apparatus: Chemostat with media feed and waste lines.

- Media: LB with 25 µg/mL chloramphenicol, 1 mM IPTG, 0.2% glucose, 5 mM target amino acid.

Methodology:

- Prepare Host Cells: Grow RP3 host cells to mid-log phase (OD600 ~0.5-0.6) in LB with antibiotics and inducers.

- Infect and Load Lagoon: Mix the SP library (~10¹¹ PFU) with 500 mL of host cells. Load the mixture into the sterile lagoon vessel.

- Start Continuous Flow: Begin feeding with fresh, pre-warmed host cell culture at a dilution rate of 1.5 volumes per hour. Ensure waste line is open.

- Monitor Evolution: Daily, collect effluent phage sample. Titer on selective and non-selective plates to track enrichment. Sequence gene III/A-domain inserts from population samples weekly.

- Isolate Variants: After 100-200 hours of evolution, plate effluent phage for isolated plaques. Screen individual clones for A-domain activity using a downstream assay (e.g., ATP-PPᵢ exchange).

Visualizations

Diagram 1: PACE System for Evolving A-Domains (100 chars)

Diagram 2: Genetic Selection Logic in PACE (94 chars)

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for NRPS A-domain Reprogramming

| Item | Function & Rationale |

|---|---|

| NNK Degenerate Primer Mixes | Enables saturation mutagenesis at specific codons, covering all 20 amino acids and a stop codon with minimal bias. Critical for creating focused A-domain libraries. |

| pIII-AtpBR Phage Selection Vector | Engineered M13 vector where gene III expression is controlled by the AtpR-responsive promoter. The cornerstone for linking phage survival to A-domain function in PACE. |

| RP3 E. coli Host Cells | Specialized host strain constitutively expressing necessary NRPS helper proteins (e.g., ArCP) and containing the T7 RNAP gene under atpR promoter control for PACE selection. |

| Non-canonical Amino Acid Stocks | High-purity (>95%) solutions of target substrate amino acids (e.g., D-amino acids, N-methylated, halogenated). Must be sterile and prepared in evolution media. |

| ATP-[³²P]PPᵢ Exchange Assay Kit | Radioactive assay to directly quantify A-domain adenylation activity and specificity by measuring ATP formed from PPᵢ and aminoacyl-AMP. Key for validation. |

| Mutator Plasmid (MP6) | Plasmid expressing an error-prone variant of DNA polymerase I. Increases mutation rate in the phage genome during PACE to accelerate evolution. |

| HPLC-MS with CID/ETD | Essential analytical tool for characterizing the final natural product output, confirming incorporation of the desired novel amino acid by evolved NRPS systems. |

Application Notes

Within a Phage-Assisted Continuous Evolution (PACE) framework for natural product biosynthetic pathway optimization, the successful isolation and sequencing of evolved gene variants is the critical endpoint that informs downstream application. This protocol details the final stages: harvesting phage pools from the PACE lagoon, isolating individual evolved phage clones, extracting the gene of interest (GOI) from the phage vector, and preparing it for next-generation sequencing (NGS) validation. Efficient execution ensures accurate retrieval of beneficial mutations that enhance enzymatic activity, alter substrate specificity, or improve pathway flux.

Key Quantitative Benchmarks: The following table summarizes target metrics for key steps in the protocol to ensure successful variant recovery.

Table 1: Key Quantitative Benchmarks for Phage Harvesting & Sequencing

| Step | Parameter | Target Value | Purpose/Rationale |

|---|---|---|---|

| Lagoon Sampling | Host Cell Density (OD600) | >0.5 | Ensures active replication; prevents sampling of "washed-out" lagoon. |

| Phage Titer | Plaque-Forming Units (PFU)/mL | 10^9 - 10^11 | Indicates healthy phage propagation and selection pressure. |

| Clone Picking | Individual Plagues Isolated | 20-50 per pool | Balances comprehensive sampling with practical screening load. |

| PCR Amplification | GOI Product Yield | >50 ng/μL (total >500 ng) | Ensures sufficient mass for robust NGS library preparation. |

| NGS Coverage | Average Read Depth per Variant | >500x | Provides confidence in identifying true mutations versus sequencing errors. |

Detailed Protocols

Protocol A: Harvesting Phage from PACE Lagoon and Plaque Isolation

Objective: To collect the evolved phage population and isolate individual clones for analysis. Materials: Sterile syringe, 0.22 μm PVDF filter, SM Buffer, E. coli host strain (same as in PACE), LB agar plates, top agar, 37°C incubator. Procedure:

- Sample Collection: Aseptically withdraw 1 mL of lagoon culture using a syringe. Pass through a 0.22 μm filter to remove host cells. The filtrate contains the evolved phage pool. Store at 4°C in SM Buffer.

- Titer Determination: Perform serial dilutions (10^-6 to 10^-9) of the filtrate in SM Buffer. Mix 10 μL of each dilution with 200 μL of log-phase E. coli host cells (OD600 ~0.5-0.6). Incubate 10 min at 37°C.

- Plaque Assay: Add the phage-bacteria mixture to 3 mL of melted top agar (45-50°C), vortex briefly, and pour onto pre-warmed LB agar plates. Swirl to cover. Let solidify and incubate overnight at 37°C.

- Clone Isolation: The next day, plates with ~100 plaques are ideal. Using a sterile pipette tip, pick 20-50 well-isolated plaques into 100 μL of SM Buffer. Elute phage by incubating at 4°C for 4-6 hours with occasional vortexing. This is your clonal phage stock.

Protocol B: Phage DNA Extraction & GOI Amplification

Objective: To isolate the engineered phage genome and specifically amplify the evolved gene of interest. Materials: Phage clonal stock, DNase I (1 U/μL), RNase A (10 mg/mL), Proteinase K (20 mg/mL), EDTA, SDS, Phenol:Chloroform:Isoamyl alcohol, Isopropanol, 70% Ethanol, TE Buffer, PCR reagents, GOI-specific primers. Procedure:

- Nuclease Treatment: To 100 μL of clonal phage stock, add 1 μL of DNase I and 1 μL of RNase A. Incubate 30 min at 37°C to degrade free nucleic acids.

- Phage Lysis & Digestion: Add EDTA (10 mM final), SDS (0.5% final), and Proteinase K (50 μg/mL final). Incubate 1-2 hours at 56°C.

- DNA Purification: Extract once with an equal volume of Phenol:Chloroform:Isoamyl Alcohol. Centrifuge at 16,000 x g for 5 min. Transfer aqueous phase.

- DNA Precipitation: Add 0.7 volumes of isopropanol, mix, and incubate at -20°C for 30 min. Centrifuge at 16,000 x g for 15 min at 4°C. Wash pellet with 70% ethanol, air-dry, and resuspend in 30 μL TE Buffer.

- GOI PCR Amplification: Using 1 μL of purified phage DNA as template, set up a 50 μL PCR reaction with high-fidelity polymerase and primers flanking the GOI insertion site in the phage vector (e.g., pIII or other). Purify PCR product using a spin column kit. Quantify yield via fluorometry.

Protocol C: NGS Library Preparation for Variant Sequencing

Objective: To prepare barcoded amplicons for pooled, deep sequencing to identify mutations. Materials: Purified GOI amplicons, NGS library prep kit (e.g., Illumina DNA Prep), dual-index barcode primers, SPRIselect beads, Qubit fluorometer, Bioanalyzer/TapeStation. Procedure:

- Tagmentation & Amplification: Following the manufacturer's protocol, fragment and tag the purified GOI amplicons. Use a limited-cycle PCR to attach unique dual indices (i5 and i7) and full Illumina adapter sequences to each sample.

- Clean-up: Purify the indexed libraries using SPRIselect beads at a ratio specified by the kit to select for the correct fragment size (~300-600 bp).

- Quantification & Pooling: Quantify each library using Qubit. Check fragment size distribution on a Bioanalyzer. Pool libraries equimolarly based on molarity (nM).

- Sequencing: Denature and dilute the pooled library according to sequencer specifications. Sequence on an Illumina MiSeq or NextSeq using a 2x150 bp or 2x250 bp run to ensure overlap and high-quality coverage across the GOI.

Diagrams

Title: Workflow for Harvesting and Sequencing Evolved Phage Genes

Title: Clonal Isolation of Evolved Phage from Plaque Assay

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Phage Harvesting and Sequencing

| Item | Function/Application | Key Consideration |

|---|---|---|

| SM Buffer (100 mM NaCl, 8 mM MgSO₄, 50 mM Tris-Cl, pH 7.5) | Stable long-term storage and dilution of phage particles. | Maintains phage integrity; essential for plaque assays. |

| 0.22 μm PVDF Syringe Filter | Sterile filtration of lagoon sample to remove bacterial host cells. | Low protein binding prevents phage loss. |

| Top Agar (LB + 0.5-0.7% Agar) | Soft overlay for plaque formation, allowing diffusion of phage. | Must be kept at 45-50°C before pouring to prevent premature solidification. |

| Proteinase K | Digests the phage capsid protein to release genomic DNA. | Critical after nuclease treatment to ensure removal of contaminating nucleic acids. |

| High-Fidelity DNA Polymerase | Error-free PCR amplification of the GOI from phage DNA for sequencing. | Minimizes introduction of PCR errors that could be mistaken for evolution-derived mutations. |

| Dual-Indexed Barcode Primers | Unique labeling of individual samples for multiplexed NGS. | Enables pooling of hundreds of samples in a single sequencing run, reducing cost. |

| SPRIselect Beads | Size-selective cleanup and purification of DNA fragments during NGS prep. | The bead-to-sample ratio is critical for optimal size selection and yield. |

Solving Common PACE Pitfalls: Optimization Strategies for Robust Evolution

Within Phage Assisted Continuous Evolution (PACE) platforms for natural product research, robust and selective phage propagation is non-negotiable. Poor propagation manifests as low titers, poor selection stringency, and failed evolution experiments. Three dominant, interlinked culprits are: Leaky Selection (inadequate host dependency), Host Toxicity (from evolving gene products), and pIII Folding/Display Issues (compromising infectivity). This Application Note details diagnostic protocols and solutions.

Table 1: Common Symptoms, Causes, and Diagnostic Metrics

| Symptom | Primary Suspected Cause | Diagnostic Assay | Typical Problematic Value (Quantitative) | Target Value for Healthy PACE |

|---|---|---|---|---|

| High phage titer in lagoon effluent without selection | Leaky Selection (Background Propagation) | Plaque Assay on -Selection vs. +Selection Hosts | >1e8 PFU/mL on -Selection host | <1e5 PFU/mL on -Selection host |

| Lagoon host cell density drops >50% | Host Toxicity from Evolved Gene | Optical Density (OD600) Monitoring in Lagoon | OD600 < 0.4 in steady-state | OD600 0.5 - 0.8 (steady-state) |

| Low infectious titer despite high DNA titer | pIII Folding/Display Defect | qPCR vs. Infectivity (Plaque) Ratio | Infectivity:Genome Ratio < 1e-4 | Infectivity:Genome Ratio > 1e-2 |

| Reduced infection rate constant | pIII or Host Receptor Issue | Phage Adsorption Assay | Adsorption Rate Constant < 1e-9 mL/min | Adsorption Rate Constant ~1e-8 mL/min |

Table 2: Key Research Reagent Solutions

| Item | Function in Troubleshooting | Example/Supplier (Note: For illustration) |

|---|---|---|

| Arabinose-Inducible pIII Expression Plasmid | Complementation test for pIII folding/function; confirms selection dependency. | e.g., pJC175e (Addgene #66425) |

| Tuner or BL21(DE3) E. coli Strains | Tuned protein expression to assess toxicity; lower basal expression. | Merck Millipore, NEB |

| Anti-pIII Monoclonal Antibody | Detect pIII display on phage via ELISA or Western Blot. | e.g., Anti-M13 pIII Antibody (ProSci) |

| Protease Inhibitor Cocktail | Included in phage lysates to prevent pIII degradation. | e.g., cOmplete, EDTA-free (Roche) |

| Chaperone Expression Plasmids (GroEL/ES, DnaK/J) | Co-expression to improve folding of evolving proteins/pIII variants. | e.g., pGro7 (Takara Bio) |

| Nitrocellulose Filter Membranes (0.45 µm) | For rapid titering and separation of phage from cells in lagoon samples. | e.g., Millipore HAWP |

Experimental Protocols

Protocol 3.1: Diagnosing Leaky Selection

Objective: Quantify background phage propagation in the absence of the required selection pressure. Materials: Lagoon effluent sample, E. coli host with selection plasmid (+Selection), isogenic host without selection plasmid (-Selection), LB agar plates, top agar. Procedure:

- Prepare serial dilutions (10-fold, in PBSMg) of the lagoon effluent phage sample.

- Mix 100 µL of each dilution with 200 µL of mid-log phase -Selection host and +Selection host in separate tubes.

- Incubate 10 min at 37°C for adsorption, add to 3 mL molten top agar (0.7% agar, 45°C), and pour onto LB agar plates.

- Incubate plates overnight at 37°C.

- Count plaques. Calculation: Leakiness = (Titer on -Selection host) / (Titer on +Selection host). A ratio > 0.1% indicates problematic leakiness.

Protocol 3.2: Assessing Host Toxicity from Phage Gene

Objective: Measure the impact of evolving gene expression on host cell growth. Materials: Lagoon sample (contains host cells), Isogenic host without phage infection, Spectrophotometer. Procedure:

- Aseptically collect 1 mL from the lagoon's chemostat vessel. Immediately dilute 1:10 in fresh LB + antibiotics to halt further infection.

- Measure OD600. Compare to the OD600 of the uninfected stock host culture used to feed the lagoon, diluted to the same nominal dilution factor.

- For direct toxicity of the gene of interest, clone it into an inducible plasmid (e.g., pBAD33). Transform into host strain. Induce with a range of arabinose concentrations (0.001%-0.2%) and monitor growth curve (OD600 every 30 min for 8-12 hrs) vs. uninduced control.

Protocol 3.3: pIII Folding/Display Analysis

Objective: Determine if low infectivity is due to insufficient or misfolded pIII. Materials: Concentrated phage particles, anti-pIII antibody, anti-M13 HRP conjugate, qPCR reagents, primers for phage genome. Part A: Infectivity-to-Genome Ratio

- Infectivity Titer: Perform standard plaque assay on appropriate host.

- Genome Titer: Extract phage DNA (boiling prep). Perform qPCR with standard curve generated from known phage genome copies.

- Calculate Ratio: (PFU/mL) / (Genome Copies/mL). A low ratio (<1e-4) suggests display/folding issues. Part B: pIII Detection ELISA

- Coat ELISA plate with 1e10 phage particles per well in carbonate buffer overnight at 4°C.

- Block with 5% BSA. Incubate with anti-pIII primary antibody (1:1000), then anti-mouse HRP secondary.

- Develop with TMB substrate. Compare signal to control phage with known good pIII display.

Visualizations

Title: PACE Troubleshooting Decision Pathway

Title: Phage Titer & pIII Analysis Workflow

Phage-Assisted Continuous Evolution (PACE) has emerged as a transformative platform for the rapid evolution of biomolecules, including enzymes involved in natural product biosynthesis. A critical component of PACE is the Mutagenesis Plasmid (MP), which drives genetic diversity in the evolving gene of interest (GOI) hosted within the host E. coli cell. The MP encodes a mutagenic DNA polymerase (e.g., a variant of DNA Pol I) under the control of an inducible promoter. The strength of the MP—determined by the potency of the polymerase and its expression level—directly dictates the mutation rate. This application note details protocols and strategies for optimizing MP strength to maximize the generation of beneficial mutations while minimizing the accumulation of deleterious mutations and intact phage loss, thereby balancing mutagenesis with library quality for successful natural product pathway enzyme evolution.

Table 1: Components Influencing MP Strength and Library Quality

| Parameter | Definition | Impact on Mutation Rate | Impact on Library Quality | Optimal Range for PACE (Natural Products) |

|---|---|---|---|---|

| Polymerase Fidelity | Error rate (mutations/bp/duplication) of the MP-encoded polymerase. | Directly proportional: Lower fidelity = higher rate. | Inverse correlation: Very low fidelity increases non-functional variants. | 10⁻⁵ to 10⁻⁶ errors/bp. |

| MP Copy Number | Plasmid copies per cell. | Higher copy number increases total mutagenic polymerase. | Can burden host metabolism, reducing phage titers. | Moderate (15-30 copies/cell). |

| Inducer Concentration | Concentration of arabinose (if using pBAD promoter) or other inducer. | Directly controls polymerase expression level. | Critical for tuning; too high leads to collapse. | Must be empirically determined (e.g., 0.001%-0.1% L-arabinose). |