Optimizing Cofactor Recycling in Enzymatic Synthesis: Strategies for Cost-Effective Biomanufacturing and Drug Development

This article provides a comprehensive overview of advanced strategies for optimizing cofactor recycling in enzymatic synthesis, a critical challenge in making biocatalysis economically viable for pharmaceutical production and biorefinery applications.

Optimizing Cofactor Recycling in Enzymatic Synthesis: Strategies for Cost-Effective Biomanufacturing and Drug Development

Abstract

This article provides a comprehensive overview of advanced strategies for optimizing cofactor recycling in enzymatic synthesis, a critical challenge in making biocatalysis economically viable for pharmaceutical production and biorefinery applications. Tailored for researchers, scientists, and drug development professionals, we explore foundational principles, diverse methodological approaches including enzyme co-immobilization and cell-free systems, troubleshooting for common bottlenecks, and validation through case studies in continuous-flow reactors and natural product synthesis. By synthesizing recent advances from heterogeneous biocatalysts to metabolic engineering, this review serves as a strategic guide for implementing efficient cofactor regeneration systems that significantly reduce production costs while enhancing sustainability in biomedical and industrial biotechnology.

The Critical Role of Cofactor Recycling: Understanding Economic and Biochemical Fundamentals

In industrial biocatalysis, many of the most valuable enzymes, particularly oxidoreductases and ligases, require non-protein organic cofactors to function. Cofactors like NAD(P)+/NAD(P)H and ATP/ADP are essential for transferring chemical groups or electrons in catalytic reactions. However, using them in stoichiometric amounts—where one mole of cofactor is consumed for every mole of product formed—is economically unfeasible at an industrial scale due to their exceptionally high cost.

The economic challenge is stark: the market price for a mole of oxidized nicotinamide adenine dinucleotide phosphate (NADP+) is approximately $22,000 [1]. For a process aiming to produce tons of material, this cost is prohibitively expensive. Cofactor recycling resolves this fundamental economic challenge by regenerating the active form of the cofactor after each catalytic cycle, allowing a single cofactor molecule to be reused thousands of times. This transforms the cofactor from a stoichiometric reagent into a catalytic entity, dramatically reducing the cost contribution per kilogram of final product and making enzymatic processes economically viable for industrial manufacturing [2] [3].

Troubleshooting Guide: Common Cofactor Recycling Challenges

FAQ 1: Why is my multi-enzyme cascade reaction slowing down prematurely, even with active enzymes?

- Potential Cause: Cofactor depletion or imbalance. In cascades involving oxidation and reduction steps, an imbalance in the regeneration of NAD(P)+/NAD(P)H can halt the reaction.

- Solution: Implement a closed-loop recycling system. Design your cascade so that the co-product from one reaction serves as the substrate for another, creating a redox-neutral cycle. For example, in the synthesis of (1R,2R)-1-phenylpropane-1,2-diol, the co-product benzaldehyde generated during NADPH regeneration is directly consumed as a substrate in the carboligation step, eliminating accumulation and driving the reaction to completion [4].

- Prevention: During cascade design, map the redox balance and ensure cofactor regeneration is tightly coupled to the main synthesis steps.

FAQ 2: Why does my cell-free protein synthesis (CFPS) system have a short productive lifespan?

- Potential Cause: Accumulation of inhibitory by-products from inefficient ATP regeneration. The commonly used phosphoenolpyruvate (PEP) system can lead to a build-up of inorganic phosphate, which inhibits protein synthesis [5].

- Solution: Switch to alternative ATP regeneration strategies. Use glycolytic intermediates like glucose-6-phosphate (G6P) or pyruvate as secondary energy sources. These substrates prolong the reaction period by mitigating inhibitor accumulation and result in more ATP being readily available, thus increasing yield [5].

- Prevention: Characterize the by-products of your chosen cofactor regeneration system and assess their impact on the primary enzymatic reaction.

FAQ 3: How can I make my biocatalytic process more sustainable while also reducing costs?

- Potential Cause: The use of traditional chemical synthesis or biocatalytic processes with poor atom economy.

- Solution: Integrate cofactor recycling with flow biocatalysis. Immobilizing enzymes and cofactor regeneration systems in a packed-bed flow reactor enhances sustainability by:

- Improving Atom Economy: Recycling cascades minimize waste production [4].

- Reducing Enzyme Consumption: Enzyme immobilization allows for continuous reuse over long periods [6] [7].

- Lowering Energy Input: Flow systems operate under mild, controlled conditions with efficient mass transfer, reducing energy requirements compared to traditional batch processing [8] [6].

- Prevention: Adopt a holistic process design that prioritizes green chemistry principles, such as integrating cofactor recycling with continuous flow manufacturing from the outset.

Experimental Protocols & Methodologies

Protocol: Enzymatic NADP+ Regeneration Using a Glutathione Reductase System

This protocol, adapted from Allemann et al., outlines a highly efficient method for regenerating the oxidized cofactor NADP+ from NADPH, leveraging inexpensive organic disulfides [1].

- Principle: The system mimics a natural cellular pathway. It uses an organic disulfide as an oxidizing agent, which is reduced. Bacterial glutaredoxin and glutathione reductase then work in tandem to recycle the disulfide and ultimately oxidize NADPH back to NADP+.

- Key Advantage: This system could reduce the recurrent cost of NADP+ to an estimated $0.05 per mole, a reduction of more than five orders of magnitude compared to its purchase price [1].

Step-by-Step Procedure:

- Reaction Setup: In a suitable buffer (e.g., Tris-HCl or phosphate buffer, pH 7.5-8.5), combine the following components:

- Cofactor: NADPH (catalytic amount, e.g., 0.1-1 mM).

- Oxidizing Agent: An inexpensive organic disulfide (e.g., 5-20 mM).

- Enzyme System: Recombinant bacterial glutaredoxin and glutathione reductase.

- Main Substrate & Enzyme: Your target substrate and the NADP+-dependent oxidoreductase of interest.

- Initiation: Start the reaction by adding the main enzyme.

- Monitoring: Monitor the reaction progress by tracking substrate consumption or product formation using HPLC, GC, or spectrophotometric assays. The maintenance of NADP+ levels ensures sustained enzyme activity.

- Control: Run a control reaction without the regeneration system to demonstrate the necessity of cofactor recycling for achieving high total turnover number (TTN).

Protocol: ATP Regeneration for Cell-Free Systems Using Glycolytic Intermediates

This protocol provides an alternative to the standard PEP system for ATP regeneration in cell-free protein synthesis or biocatalysis, helping to avoid phosphate inhibition [5].

- Principle: Glycolytic intermediates like glucose-6-phosphate (G6P) or pyruvate are used to fuel the endogenous metabolic pathways in the cell extract, leading to a more sustained and higher-yield regeneration of ATP from ADP.

Step-by-Step Procedure:

- System Preparation: Prepare an E. coli or other suitable cell extract for CFPS according to standard methods.

- Energy Mix Formulation: Replace phosphoenolpyruvate (PEP) in the standard energy mix with either:

- Glucose-6-phosphate (G6P): Typically used at 20-50 mM.

- Pyruvate: Typically used at 20-50 mM, sometimes with the addition of pyruvate oxidase to generate acetyl phosphate in situ.

- Reaction Assembly: Combine the cell extract, energy mix, DNA template (or amino acids and cofactors for biocatalysis), and other necessary components.

- Incubation and Analysis: Incubate the reaction mixture at the optimal temperature (e.g., 30-37°C) and monitor protein synthesis or product formation over time. Compared to the PEP system, the productive reaction time and final yield should be significantly increased [5].

The Scientist's Toolkit: Key Research Reagent Solutions

The table below details essential reagents and their functions in setting up efficient cofactor recycling systems.

Table 1: Key Reagents for Cofactor Recycling Systems

| Reagent | Function in Cofactor Recycling | Key Characteristics & Examples |

|---|---|---|

| Formate Dehydrogenase (FDH) | Enzyme-coupled regeneration of NADH. Oxidizes formate to CO2 while reducing NAD+ to NADH. | Co-product (CO2) leaves the reaction mixture, shifting equilibrium. High Total Turnover Number (TTN) [2] [3]. |

| Glucose Dehydrogenase (GDH) | Enzyme-coupled regeneration of NAD(P)H. Oxidizes glucose to gluconolactone while reducing NAD(P)+. | Widely used, but co-product (gluconate) accumulates, which may require separation [4]. |

| NAD(P)H Oxidase (NOX) | Regeneration of NAD(P)+. Oxidizes NAD(P)H to NAD(P)+, typically reducing O2 to H2O or H2O2. | H2O-forming NOX is preferred for better enzyme compatibility. Used in rare sugar synthesis (e.g., L-tagatose) [9]. |

| Phosphoenolpyruvate (PEP) / Pyruvate Kinase | Regeneration of ATP from ADP. PEP is converted to pyruvate, transferring a phosphate group to ADP. | Common but can cause phosphate inhibition. [5] |

| Acetyl Phosphate / Acetate Kinase | Regeneration of ATP from ADP or AMP. Acetyl phosphate acts as a phosphate donor. | Endogenous acetate kinase in E. coli extracts makes it economically attractive [5]. |

| "Smart Cosubstrates" (e.g., Benzyl Alcohol) | Substrate-coupled regeneration. The same enzyme (e.g., ADH) uses the cosubstrate to regenerate cofactor. | In cascades, the co-product (e.g., benzaldehyde) can be a substrate for another step, creating a recycling cascade with high atom economy [4]. |

| Lactose octaacetate | Lactose octaacetate, MF:C28H38O19, MW:678.6 g/mol | Chemical Reagent |

| Casp8-IN-1 | Casp8-IN-1, MF:C24H28ClN3O3, MW:441.9 g/mol | Chemical Reagent |

Visualization of Workflows and Relationships

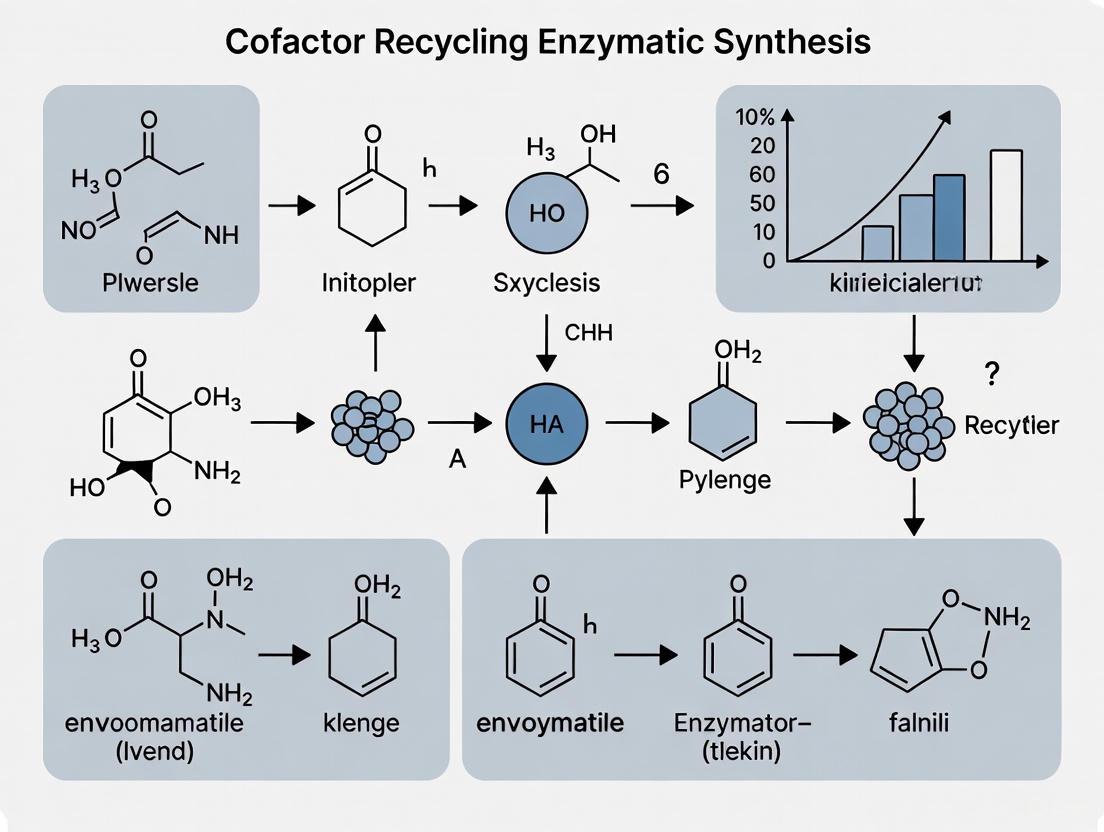

The following diagram illustrates the logical relationship between the economic challenge, the solution provided by cofactor recycling, and the resulting technical and commercial outcomes.

Figure 1: The logical pathway from economic challenge to viable bioprocesses.

The workflow below details the specific experimental steps involved in implementing a cofactor and co-product recycling cascade for efficient synthesis.

Figure 2: Experimental workflow for a co-product recycling cascade.

In enzymatic synthesis and metabolic engineering, cofactors are essential non-protein molecules that enable enzymes to catalyze critical biochemical transformations. Efficient cofactor recycling is a cornerstone of optimizing these processes, particularly for the production of high-value chemicals and pharmaceuticals. Without effective regeneration, these expensive molecules would need to be supplied in stoichiometric quantities, making industrial-scale applications economically unviable [5] [10]. This technical support center focuses on the key cofactors NAD(P)H, ATP, Coenzyme A (CoA), and Pyridoxal Phosphate (PLP), providing targeted troubleshooting and methodologies to enhance their recycling within your experimental systems.

The recyclability of cofactors—their ability to transition between oxidized and reduced forms or to be recharged with essential chemical groups—allows a small pool of molecules to drive countless reactions. This review integrates these principles within the broader thesis that optimizing cofactor recycling is not merely a supportive activity but a central strategy for unlocking the full potential of enzymatic synthesis, from laboratory-scale experiments to industrial biomanufacturing.

The following table summarizes the core cofactors, their biochemical functions, and associated recycling challenges.

Table 1: Essential Cofactors in Enzymatic Synthesis: Functions and Recycling Challenges

| Cofactor | Primary Biochemical Role | Vitamin Precursor | Common Recycling Challenges |

|---|---|---|---|

| NAD(P)H | Electron carrier in redox reactions; crucial for reductive biosynthesis and energy metabolism [11] [10]. | Niacin (B3) [10] | Imbalance in NAD+/NADH or NADP+/NADPH ratios; enzyme inhibition by excess reduced cofactor; substrate depletion [5] [9]. |

| ATP | Universal "energy currency"; phosphorylating agent for kinases and energy-intensive reactions [5]. | Pantothenic Acid (B5) [10] | Rapid depletion in cell-free systems; accumulation of inhibitory phosphate by-products (e.g., from PEP) [5]. |

| Coenzyme A (CoA) | Acyl group carrier and activator; central to fatty acid metabolism and synthesis of secondary metabolites [5]. | Pantothenic Acid (B5) [10] | Limited availability in engineered pathways; consumption in multi-enzyme cascades, leading to accumulation of acyl-CoA intermediates [5]. |

| Pyridoxal Phosphate (PLP) | Cofactor for a wide range of enzymes, including transaminases, decarboxylases, and racemases involved in amino acid metabolism [12]. | Pyridoxine (B6) [10] | Less focus on recycling in literature; often supplied stoichiometrically; stability can be an issue under non-optimal pH conditions. |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Research Reagents for Cofactor Recycling Studies

| Reagent / Tool | Function / Application | Example Use Case |

|---|---|---|

| H₂O-forming NADH Oxidase (NOX) | Regenerates NAD⺠from NADH, producing water as a benign by-product; superior compatibility in enzymatic reactions compared to H₂O₂-forming NOX [9] [13]. | Coupled with dehydrogenases for the enzymatic synthesis of rare sugars like L-tagatose and L-xylulose [9]. |

| Acetate Kinase (ACK) / Acetyl Phosphate | Efficient and economical system for ATP regeneration from ADP, using acetyl phosphate as a phosphate donor [5]. | Used in cell-free protein synthesis and sugar nucleotide production to maintain ATP levels [5]. |

| Polyphosphate Kinase (PPK) | Regenerates ATP from ADP using inexpensive polyphosphate as a phosphate donor [5]. | An alternative to ACK system, often used to avoid inhibitory by-products. |

| Glucose-6-Phosphate (G6P) | A glycolytic intermediate used as a secondary energy source to prolong ATP regeneration in cell-free systems, offering a cheaper and longer-lasting alternative to phosphoenolpyruvate (PEP) [5]. | Sustaining long-duration cell-free protein synthesis reactions [5]. |

| Coenzyme A Assay Kit | Allows for easy and accurate measurement of CoA levels in various biological samples (e.g., plasma, serum, tissue extracts) [10]. | Quantifying CoA pool dynamics during metabolic engineering for D-pantothenic acid production. |

| Purified NADP Coenzyme | High-purity (≥93%) coenzyme used to support redox reactions in cytochrome P450 and other oxidase/reductase systems for in vitro studies [10]. | Supplementing cell-free biocatalysis systems for functional studies. |

| Pseudoalterobactin B | Pseudoalterobactin B, MF:C41H63N13O21S, MW:1106.1 g/mol | Chemical Reagent |

| Aspergillic acid | Aspergillic acid, CAS:490-02-8, MF:C12H20N2O2, MW:224.30 g/mol | Chemical Reagent |

Troubleshooting Guides and FAQs

NAD(P)H-Related Issues

Problem: Incomplete Conversion or Stalling in Reductive Biocatalysis

- Observation: A dehydrogenase-catalyzed reaction starts but slows prematurely, failing to reach full substrate conversion.

- Potential Causes & Solutions:

- Cause 1: NAD(P)⺠Pool Depletion. The reaction has run out of oxidized cofactor.

- Cause 2: Cofactor Inhibition. The target dehydrogenase may be inhibited by high concentrations of NAD(P)H.

- Solution: Optimize the initial concentration of NAD(P)+ and use a regulated regeneration system to prevent the buildup of the reduced form. For instance, sorbitol dehydrogenase from Gluconobacter oxydans is inhibited by NADPH, necessitating careful cofactor management [9].

- Cause 3: Inefficient Cofactor Specificity. The enzyme may have low affinity for the cofactor pool you are trying to use (e.g., preferring NADPH over NADH).

- Solution: Consider protein engineering to alter cofactor specificity. A mutant of Bacillus subtilis malate dehydrogenase (BsMDH-T7) was engineered to have a significantly higher affinity for NADPH over NADH [10].

FAQ: How can I reduce the cost of using expensive NAD+ in large-scale enzymatic reactions? The key is efficient cofactor regeneration. Using a coupled enzyme system with a robust NADH oxidase (NOX) allows you to add only a catalytic amount of NAD+ (e.g., 3 mM), as it is continuously recycled from NADH back to NAD+, driving the reaction to completion and significantly lowering costs [9] [13].

ATP-Related Issues

Problem: Low Yield in ATP-Dependent Cell-Free Synthesis

- Observation: Cell-free protein synthesis or other ATP-intensive reactions produce low yields, with ATP levels dropping rapidly.

- Potential Causes & Solutions:

- Cause 1: Inefficient ATP Regeneration System.

- Solution: Evaluate alternative phosphate donors. While PEP is common, it can lead to short reaction durations and phosphate accumulation. Switching to glucose-6-phosphate (G6P) or acetyl phosphate (with acetate kinase) can prolong the reaction and improve ATP availability [5]. Pyruvate can also be used with pyruvate oxidase to generate acetyl phosphate in situ [5].

- Cause 2: Inaccurate ATP Monitoring.

- Solution: Directly measure ATP concentrations during the reaction using a luciferase-based assay to accurately profile the performance of your regeneration system and identify the point of failure.

- Cause 1: Inefficient ATP Regeneration System.

FAQ: What are the pros and cons of different ATP regeneration systems?

- Phosphoenolpyruvate (PEP) / Pyruvate Kinase:

- Pros: High-energy phosphate donor, widely used.

- Cons: Expensive, can lead to short reaction times and inhibitory phosphate accumulation [5].

- Acetyl Phosphate / Acetate Kinase:

- Pros: Cost-effective; acetate kinase is abundant in E. coli extracts [5].

- Cons: Acetyl phosphate can be chemically unstable.

- Polyphosphate / Polyphosphate Kinase (PPK):

- Pros: Very inexpensive substrate (polyphosphate) [5].

- Cons: May have slower kinetics in some systems.

General Cofactor Management

Problem: Unbalanced Metabolism in Engineered Strains

- Observation: A metabolically engineered microbial factory for a cofactor-intensive product (e.g., D-pantothenic acid) shows poor growth and low yield despite high pathway enzyme expression.

- Potential Causes & Solutions:

- Cause: Cofactor Imbalance (e.g., Redox, Energy). Overexpression of a biosynthetic pathway can create a drain on specific cofactors (e.g., NADPH), disrupting central metabolism.

- Solution: Employ integrated cofactor engineering. This involves:

- Enhancing Supply: Modifying carbon flux (e.g., through the Pentose Phosphate Pathway) to boost NADPH regeneration [14].

- Managing Demand: Introducing a transhydrogenase system to convert excess NADPH and NADH into ATP, coupling redox and energy balance [14].

- Fine-tuning Expression: Rather than simply overexpressing genes, fine-tune the expression of subunits of complexes like ATP synthase to optimize energy levels without causing metabolic burden [14].

- Cause: Cofactor Imbalance (e.g., Redox, Energy). Overexpression of a biosynthetic pathway can create a drain on specific cofactors (e.g., NADPH), disrupting central metabolism.

Diagram 1: A systematic troubleshooting workflow for addressing cofactor imbalance in engineered microbial strains, integrating diagnosis with multi-pronged engineering solutions.

Detailed Experimental Protocols

Protocol: Coupled Enzymatic Synthesis with NAD+ Regeneration

This protocol outlines the procedure for synthesizing L-tagatose from galactitol using galactitol dehydrogenase (GatDH) coupled with an Hâ‚‚O-forming NADH oxidase (SmNox) for NAD+ regeneration, achieving yields up to 90% [9] [13].

Table 3: Reaction Setup for L-Tagatose Synthesis with Cofactor Recycling

| Component | Final Concentration | Notes / Function |

|---|---|---|

| Tris-HCl Buffer (pH 7.5) | 50 mM | Provides optimal pH environment for both enzymes. |

| D-Galactitol | 100 mM | Substrate for the reaction. |

| NAD+ | 3 mM | Catalytic amount; continuously regenerated. |

| GatDH (Galactitol Dehydrogenase) | 5 U/mL | Catalyzes the oxidation of galactitol to L-tagatose, reducing NAD+ to NADH. |

| SmNox (NADH Oxidase) | 10 U/mL | Reoxidizes NADH to NAD+, completing the recycling loop. |

| MgClâ‚‚ | 1 mM | Often a required cofactor for oxidase activity. |

| Total Reaction Volume | 1.0 mL | Can be scaled as needed. |

Procedure:

- Prepare the reaction mixture by adding all components, in the order listed, to a 1.5 mL microcentrifuge tube on ice. Add the enzymes last.

- Mix the reaction mixture gently by pipetting and incubate at 37°C for 12 hours with mild shaking (e.g., 200 rpm).

- After incubation, terminate the reaction by heating the tube at 80°C for 10 minutes to denature the enzymes.

- Centrifuge the tube at 14,000 x g for 5 minutes to pellet denatured protein.

- Analyze the supernatant for L-tagatose production and conversion yield using a suitable method, such as High-Performance Liquid Chromatography (HPLC) with a refractive index detector.

Protocol: Assessing ATP Regeneration Strategies in CFPS

This methodology describes a comparative assay to evaluate the efficiency of different secondary energy sources for sustaining ATP levels in a Cell-Free Protein Synthesis (CFPS) system [5].

Reagents:

- E. coli or other cell extract for CFPS.

- DNA template for a reporter protein (e.g., GFP).

- Reaction mixture containing amino acids, salts, and nucleotides.

- Secondary energy sources: Phosphoenolpyruvate (PEP), Glucose-6-Phosphate (G6P), and Acetyl Phosphate. Prepare stock solutions at appropriate concentrations.

Procedure:

- Set up three identical base CFPS reactions according to your standard protocol, omitting the secondary energy source.

- Supplement each reaction with a different energy source:

- Reaction A: 20 mM Phosphoenolpyruvate (PEP)

- Reaction B: 20 mM Glucose-6-Phosphate (G6P)

- Reaction C: 20 mM Acetyl Phosphate

- Incubate the reactions at the optimal temperature (e.g., 30-37°C) for protein synthesis.

- Monitoring: At regular intervals (e.g., 0, 30, 60, 120 minutes), take small aliquots (e.g., 10 µL) from each reaction.

- Measure ATP concentration using a commercially available bioluminescent assay.

- Measure protein yield (e.g., GFP fluorescence or colorimetric assay).

- Analysis: Plot ATP concentration and protein yield over time for each energy source. G6P and acetyl phosphate are expected to sustain ATP levels and protein synthesis for a longer duration than PEP [5].

Diagram 2: A workflow for experimentally comparing the effectiveness of different ATP regeneration systems in a cell-free protein synthesis (CFPS) reaction.

In enzymatic synthesis research, efficient cofactor regeneration is a critical determinant of process viability and cost-effectiveness. Cofactors like NAD(P)+/NAD(P)H and ATP are essential for powering oxidoreductases and kinases but are too expensive to add in stoichiometric quantities. Researchers therefore must choose between implementing these reactions within cellular systems (using living microorganisms) or cell-free systems (using purified enzymatic machinery in vitro). This technical support article provides a comparative analysis and troubleshooting guide for selecting and optimizing these distinct platforms for your cofactor-dependent biotransformations, framed within the context of optimizing cofactor recycling.

System Comparison: Cellular vs. Cell-Free Platforms

The table below summarizes the core characteristics of each system to guide your initial platform selection.

Table 1: Core Characteristics of Cellular and Cell-Free Systems for Cofactor Regeneration

| Feature | Cellular Systems | Cell-Free Systems |

|---|---|---|

| System Complexity | Intact living cells (e.g., E. coli, yeast) [15] | Crude cell extracts or purified enzymes (e.g., PURE system) [16] [17] |

| Typical Cofactor Regeneration Strategy | Endogenous metabolism (e.g., glycolysis, oxidative phosphorylation) [16] | Exogenous energy systems (e.g., substrate-level phosphorylation, creatine phosphate) [16] or engineered enzymes (e.g., NADH oxidase) [9] |

| Primary Advantage | High scalability; inherent cofactor regeneration via central metabolism; complex post-translational modifications [15] | Open, controllable environment; rapid prototyping; no cell viability constraints; high tolerance to toxic substrates/products [16] [17] |

| Key Limitation | Cofactor imbalance can cause metabolic burden; cellular membrane limits substrate/product transport [18] [17] | Limited operational lifetime; higher cost for large-scale synthesis; can lack complex cellular machinery [15] [17] |

| Ideal Application Scope | Large-scale production of proteins and metabolites where cellular metabolism is favorable [15] | Pathway prototyping, toxic product synthesis, high-throughput enzyme screening, and specialized in vitro biotransformations [16] [19] |

Troubleshooting Guide: Cofactor Regeneration Issues

Low Cofactor Recycling Efficiency in Cellular Systems

- Problem: The target reaction yield is low, and analysis indicates insufficient regeneration of the required cofactor (e.g., NAD+), leading to metabolic imbalance and cell burden [18].

- Solutions:

- Engineer Cofactor Supply: Introduce or overexpress enzymes that regenerate the target cofactor. For example, introduce glucose dehydrogenase (GDH) and gluconate kinase (GntK) to create a system that synergistically enhances the supply of NADH and FADH2 [18].

- Modulate Central Metabolism: Use metabolic engineering to redirect carbon flux. This can be combined with metabolomic analysis to identify and alleviate bottlenecks in pathways that supply reducing power or ATP [18].

- Use Engineered Hosts: Consider switching to a host organism whose native metabolism is more aligned with your cofactor demand. For instance, autotrophic hosts can be exploited for C1 substrate conversions [16].

Poor Cofactor Stability and Regeneration in Cell-Free Systems

- Problem: The cell-free reaction depletes cofactors rapidly, and the exogenous regeneration system fails to maintain sufficient cofactor levels over the desired reaction time.

- Solutions:

- Optimize the Energy System: Ensure your energy system is matched to the cofactor type. For ATP regeneration, systems using polyphosphate kinase (PPK) are highly efficient [20] [21]. For NAD+ regeneration, H2O-forming NADH oxidase (NOX) is preferred due to its good compatibility in aqueous solutions [9].

- Employ Multi-Enzyme Cascades: Design modular cascades where the cofactor consumed by your target enzyme is regenerated by a second, coupled enzyme. The use of a "plug-and-play" enzymatic strategy allows for flexible and efficient cofactor recycling across diverse reactions [21].

- Consider Hybrid Systems: For complex pathways, mixing cell extracts from different organisms (e.g., cyanobacteria and E. coli) can combine unique metabolic capabilities and provide native cofactor regeneration pathways that are otherwise missing [16].

Low Total Turnover Number (TTN) of Cofactors

- Problem: The number of catalytic cycles per cofactor molecule (TTN) is too low for the process to be economically viable.

- Solutions (Applicable to Both Systems):

- Enzyme Engineering: Improve the catalytic efficiency of the cofactor-dependent enzyme or the regeneration enzyme. Techniques like directed evolution can be used to reshape the catalytic pocket or mutate the substrate-binding domain, leading to higher catalytic efficiency and better cofactor utilization [9] [21].

- Cofactor Engineering: Utilize analog-sensitive enzyme variants that can utilize cheaper, more stable cofactor analogs [8].

- Process Optimization: In cellular systems, implement phased pH control and optimized induction timing in bioreactors to maximize cell density and cofactor regeneration capacity [18]. In cell-free systems, reagent replenishment or continuous-flow setups can extend reaction duration and TTN.

Frequently Asked Questions (FAQs)

Q1: Can cell-free prototyping reliably predict the performance of a pathway in a cellular system? A1: Correlation can be high but is not guaranteed. Cell-free prototyping can predict cellular performance with high correlation (e.g., R² ~0.75 in some studies) for anabolic pathways, especially when using extracts from the same target organism [16]. However, the correlation decreases for longer pathways with more metabolic branch points or when the catabolic state of the cell plays a prominent role [16]. The primary strength of cell-free is the rapid screening of hundreds of enzyme variants to identify high-performers, which compensates for a potentially lower correlation [16].

Q2: What are the best practices for regenerating ATP in cell-free systems? A2: While sacrificial substrates like creatine phosphate can be used, one of the most efficient and cost-effective methods is to use polyphosphate kinase (PPK), which regenerates ATP from ADP using inexpensive polyphosphate [20] [21]. This approach has been successfully integrated into multi-enzyme cascades for the synthesis of high-value compounds [21].

Q3: My enzyme requires NADPH instead of NADH. How does this change the regeneration strategy? A3: The principles are similar, but the specific enzymes differ. You would need to employ a NADPH oxidase instead of an NADH oxidase [9]. Be mindful that some enzymes, like certain sorbitol dehydrogenases, can be inhibited by high concentrations of NADPH, which would require careful tuning of the regeneration system to maintain optimal cofactor levels [9].

Q4: When should I consider a multi-enzyme cascade for cofactor regeneration? A4: Multi-enzyme cascades are ideal when you need to drive a thermodynamically unfavorable reaction, or when you can design a self-sustaining system that recycles all cofactors and byproducts. A key example is the synthesis of non-canonical amino acids from glycerol, where cascades efficiently convert a low-cost substrate into high-value products with water as the sole byproduct, achieving excellent atom economy [21].

Essential Experimental Workflows

Workflow for Setting Up a Cell-Free Cofactor Regeneration System

The following diagram illustrates a generalized workflow for designing and executing a cell-free experiment with cofactor regeneration.

Diagram 1: Cell-Free Cofactor Regeneration Workflow

Protocol: Implementing a Coupled Enzyme System for NAD+ Regeneration [9]

- Reaction Setup: In a suitable buffer, combine the following components:

- Primary Substrate: e.g., 100 mM galactitol for L-tagatose production.

- Catalytic Cofactor: e.g., 3 mM NAD+.

- Target Dehydrogenase: e.g., Galactitol Dehydrogenase (GatDH).

- Regeneration Enzyme: H2O-forming NADH Oxidase (NOX).

- Initiation and Incubation: Initiate the reaction by adding the enzyme mixture. Incubate at the optimal temperature and pH (e.g., 30-37°C, pH 7.0-8.0) for a defined period (e.g., 12 hours).

- Monitoring: Monitor product formation (e.g., L-tagatose) using HPLC or other analytical methods. The yield should be high (e.g., 90%) with minimal byproducts.

Workflow for Engineering a Cellular System for Enhanced Cofactor Supply

The diagram below outlines a metabolic engineering approach to improve cofactor regeneration within a cellular host.

Diagram 2: Cellular Cofactor Engineering Workflow

Protocol: Enhancing Cofactor Supply for L-DOPA Synthesis in E. coli [18]

- Strain Engineering:

- Establish a de novo L-DOPA synthesis pathway by optimizing promoters, RBS, and plasmid copy number for key enzymes.

- Introduce glucose dehydrogenase (BmgdH) and gluconate kinase (gntK) to construct a cofactor regeneration system that synergistically enhances NADH and FADH2 supply.

- Flux Analysis and Modulation: Use metabolomics to identify flux bottlenecks. Redirect carbon metabolism to increase precursor availability, boosting product titer.

- Bioreactor Process:

- Scale cultivation to a 5 L bioreactor.

- Implement phased pH control and optimize induction timing.

- This integrated approach achieved an L-DOPA titer of 60.73 g/L, demonstrating high efficiency.

The Scientist's Toolkit: Key Reagents and Solutions

Table 2: Essential Research Reagents for Cofactor Regeneration Systems

| Reagent / Enzyme | Function in Cofactor Regeneration | Example Application |

|---|---|---|

| NADH Oxidase (NOX) | Oxidizes NADH to NAD+, often with H2O as a byproduct, enabling NAD+ recycling [9]. | Coupled with dehydrogenases for the synthesis of rare sugars like L-tagatose and L-xylulose [9]. |

| Polyphosphate Kinase (PPK) | Regenerates ATP from ADP and inexpensive polyphosphate [20] [21]. | Powering ATP-dependent kinases in multi-enzyme cascades for ncAAs synthesis [21]. |

| Glucose Dehydrogenase (GDH) | Oxidizes glucose, concurrently reducing NAD(P)+ to NAD(P)H, for reductive biocatalysis [18]. | Used in whole-cell systems to enhance the supply of reducing equivalents for L-DOPA production [18]. |

| Formate Dehydrogenase (FDH) | Oxidizes formate to CO2, reducing NAD+ to NADH. A common and well-characterized system. | A classic pair for NADH regeneration in asymmetric synthesis. |

| Phosphoenolpyruvate (PEP) / Pyruvate Kinase (PK) | PEP is a high-energy phosphate donor; PK transfers this phosphate to ADP, regenerating ATP. | A standard ATP regeneration system in cell-free protein synthesis and metabolism [16]. |

| O-phospho-L-serine sulfhydrylase (OPSS) | A PLP-dependent enzyme that utilizes a wide range of nucleophiles to synthesize non-canonical amino acids, often with efficient cofactor turnover [21]. | Core catalyst in modular multi-enzyme cascades producing ncAAs from glycerol [21]. |

| Antibiofilm agent-16 | Antibiofilm agent-16, MF:C26H26F2N6O12P2, MW:714.5 g/mol | Chemical Reagent |

| Aranciamycin A | Aranciamycin A, MF:C26H28O10, MW:500.5 g/mol | Chemical Reagent |

In enzymatic synthesis, many oxidoreductases and transferases require non-protein cofactors such as NAD(P)H, ATP, or acetyl CoA to function. As these cofactors are too expensive to be used stoichiometrically, efficient cofactor regeneration is essential for economically viable bioprocesses. Two key metrics define the efficiency of these systems: the Turnover Number (TTN or TON) and Thermodynamic Driving Force.

The Total Turnover Number (TTN) represents the total moles of product formed per mole of cofactor during the complete reaction. For a process to be economically viable, TTNs of 10³ to 10ⵠare typically required [22] [23]. The thermodynamic efficiency relates to the Gibbs free energy change of the regeneration reaction; strongly exergonic (energy-releasing) reactions provide a powerful driving force that shifts the equilibrium toward product formation, enhancing overall conversion yields [24].

This guide addresses common challenges researchers face in achieving high TTN and robust thermodynamic efficiency in their biocatalytic systems.

Key Concepts & Quantitative Benchmarks

Defining Turnover Number:kcatvs. TTN

In biocatalysis literature, the term "turnover number" can have distinct meanings, which is a common source of confusion.

kcat(Catalytic Constant): In enzymology,kcatis the maximum number of substrate molecules converted to product per active site per unit time (typically per second). It describes the intrinsic catalytic efficiency of an enzyme molecule itself [25]. It is calculated askcat = Vmax / [E], where[E]is the molar concentration of enzyme active sites.- TTN or TON (Total Turnover Number): In synthetic biocatalysis, particularly for cofactors and catalysts, TTN refers to the total moles of product formed per mole of catalyst/cofactor before it is inactivated or consumed over the entire reaction. It is a dimensionless number that reflects the operational lifetime and stability of the catalyst [22] [26]. An ideal catalyst has an infinite TTN.

Thermodynamic Driving Forces of Common Regeneration Systems

The thermodynamic favorability of a cofactor regeneration reaction is a key determinant of its success. Reactions with large, negative free energy changes (ΔG°) provide a strong driving force, pushing the main reaction toward completion. The table below summarizes key regeneration enzymes and their thermodynamic properties [24].

Table 1: Thermodynamic and Kinetic Parameters of Common Cofactor Regeneration Enzymes

| Enzyme | Reaction | Cofactor | ΔG°' (kJ/mol) | Typical TTN for Cofactor | Key Advantage |

|---|---|---|---|---|---|

| Phosphite Dehydrogenase (PtxD) | Phosphite + NAD⺠→ Phosphate + NADH | NAD⺠| -63.3 [24] | >10ⵠ[24] | Very strong thermodynamic drive; phosphate acts as buffer |

| Formate Dehydrogenase (FDH) | Formate + NAD⺠→ CO₂ + NADH | NAD⺠| -23.5 [27] | 10³ - 10ⵠ[23] | By-product (CO₂) easily removed; drives equilibrium |

| Glucose Dehydrogenase (GDH) | Glucose + NAD⺠→ Gluconolactone + NADH | NAD⺠| - | 10³ - 10ⵠ[23] | Highly active; low-cost substrate |

| Acetate Kinase (AK) | Acetyl Phosphate + ADP → Acetate + ATP | ATP | - | - | Cheap phosphate donor; simple system |

Troubleshooting Common Experimental Problems

FAQ: Low Total Turnover Number (TTN)

Q: The TTN for my NADPH cofactor is unacceptably low, making my process economically unviable. What strategies can I employ to improve it?

A: Low TTN can stem from cofactor degradation, enzyme instability, or inhibition. Consider the following solutions:

Enzyme Engineering for Stability:

- Problem: The regeneration enzyme deactivates quickly, especially at elevated temperatures or in the presence of organic solvents.

- Solution: Use engineered thermostable enzymes. For example, a thermostable phosphite dehydrogenase (RsPtxD) mutant showed a half-life of 80.5 hours at 45°C, leading to a significantly higher TTN compared to less stable wild-type enzymes [24]. Rigidifying enzyme structure can also enhance TTN, as demonstrated by a 35-fold increase in TTN for a de novo peroxidase upon stabilization [26].

Optimize Cofactor Regeneration System:

- Problem: The regeneration reaction is too slow or thermodynamically unfavorable.

- Solution: Implement a highly efficient and thermodynamically driven regeneration system. The use of formate dehydrogenase (FDH) for NADH regeneration, for instance, increased the intracellular NADH/NAD⺠ratio and boosted the yield of (2S,3S)-2,3-butanediol to 89.8% in a coupled system [27]. The strongly exergonic oxidation of phosphite by PtxD (ΔG°' = -63.3 kJ/mol) is another excellent choice for driving reactions to completion [24].

Shift to "Closed-Loop" Recycling Cascades:

- Problem: Accumulation of co-product from the regeneration reaction causes inhibition or equilibrium issues.

- Solution: Design a cascade where the co-product is consumed as a substrate for a coupled reaction. A 2-step cascade using an alcohol dehydrogenase (ADH) and a carboligase successfully recycled the co-product (benzaldehyde) back into the synthesis pathway. This overcame solubility limits, improved atom economy, and achieved high product concentrations (>100 mM) without external substrate addition [4].

FAQ: Thermodynamic Limitations

Q: The reaction equilibrium of my enzymatic synthesis is unfavorable, leading to low conversion yields. How can I shift the equilibrium?

A: To shift the equilibrium, you must couple the main reaction with an irreversible, strongly exergonic regeneration step.

Select a Regeneration Reaction with a Large -ΔG°:

- Protocol: Replace a standard regeneration enzyme (e.g., a simple alcohol dehydrogenase) with one that has a much more favorable thermodynamic profile. Phosphite dehydrogenase (PtxD) is a prime example, as its large, negative free energy change (ΔG°' = -63.3 kJ/mol) provides a powerful driving force [24].

Remove By-Products:

- Protocol: Use regeneration systems that generate gaseous or easily removable by-products. Formate dehydrogenase (FDH) converts formate to COâ‚‚, which can bubble out of the reaction mixture, preventing product inhibition and constantly pulling the equilibrium toward product formation [27]. This principle is illustrated in the diagram below.

Diagram 1: Using FDH to thermodynamically drive a synthesis. The irreversible, gaseous by-product (COâ‚‚) pulls the entire equilibrium forward.

FAQ: Cofactor Instability and Degradation

Q: My nicotinamide cofactors appear to be degrading during prolonged reactions, limiting the achievable TTN. What are the causes and solutions?

A: Cofactor degradation can occur due to enzymatic side reactions or chemical instability.

Prevent Off-Pathway Oxidation:

- Problem: The reactive intermediates of some enzymes (e.g., peroxidases) can oxidize and degrade the cofactor or the enzyme itself.

- Solution: Protein engineering can rigidify the enzyme structure to protect the active site. For example, adding 2,2,2-trifluoroethanol (TFE) to a peroxidase system stabilized a key reactive intermediate (Compound I) and reduced heme degradation, which directly increased the total turnover number [26].

Use Immobilized or Polymer-Bound Cofactors:

- Problem: Free cofactors are small molecules that can be lost in continuous-flow systems or degraded.

- Solution: Covalently bind cofactors (e.g., NADâº) to high molecular weight polymers like polyethylene glycol (PEG) or dextran. This allows for their retention in membrane reactors while maintaining activity. The density of cofactors on the polymer can be optimized for maximum activity [22].

The Scientist's Toolkit: Essential Reagents and Methods

This table provides a curated list of key reagents and enzymes for setting up efficient cofactor regeneration systems.

Table 2: Key Research Reagent Solutions for Cofactor Regeneration

| Reagent/Enzyme | Primary Function | Key Feature for Troubleshooting |

|---|---|---|

| Formate Dehydrogenase (FDH) | NADH Regeneration | Removable by-product (COâ‚‚); favorable thermodynamics; available in mutant forms for NADPH [27] [24]. |

| Engineered Phosphite Dehydrogenase (PtxD) | NADH or NADPH Regeneration | Very strong thermodynamic drive (ΔG°' = -63.3 kJ/mol); high thermostability variants available [24]. |

| Glucose Dehydrogenase (GDH) | NAD(P)H Regeneration | High specific activity; low-cost substrate (glucose). Watch for pH drop from gluconic acid production [27] [24]. |

| Polyethylene Glycol (PEG)-NAD⺠| Immobilized Cofactor | Enables cofactor retention in continuous-flow membrane reactors, potentially increasing operational TTN [22]. |

| 2,2,2-Trifluoroethanol (TFE) | Enzyme Stabilizer | Can rigidify enzyme structure, leading to enhanced activity and stability, thereby increasing TTN [26]. |

| Polyphosphate/Acetyl Phosphate | ATP Regeneration | Inexpensive phosphate donors for kinase-based ATP regeneration systems [5] [23]. |

| Purinostat Mesylate | Purinostat Mesylate, MF:C24H30N10O6S, MW:586.6 g/mol | Chemical Reagent |

| Hibarimicin C | Hibarimicin C, MF:C83H110O36, MW:1683.7 g/mol | Chemical Reagent |

Advanced Cofactor Regeneration Strategies: From Enzyme Engineering to System Design

FAQs and Troubleshooting Guide

Q1: Why does my co-immobilized biocatalyst show significantly reduced activity despite high protein loading?

A: Activity loss can stem from several factors:

- Mass Transfer Limitations: Excessive enzyme loading or dense support matrices can hinder substrate and product diffusion. This is quantified by the Thiele modulus; a high value indicates severe diffusion limitations [28].

- Unfavorable Enzyme Orientation: Non-specific immobilization methods can block active sites or restrict conformational flexibility needed for catalysis [29] [30].

- Incompatible Microenvironments: The local pH or polarity near the support surface can differ from the bulk solution, negatively impacting enzyme activity [29].

Q2: Our co-immobilized system has inefficient cofactor recycling. How can we improve this?

A: Inefficient recycling often relates to suboptimal interaction between the enzyme and the immobilized cofactor. Recent research shows that enzyme activity towards immobilized cofactors follows the Sabatier principle [31].

- The Principle: Maximum catalytic efficiency is achieved at an intermediate cofactor-carrier binding strength. If binding is too weak, the cofactor is not retained; if it's too strong, the cofactor cannot interact effectively with the enzyme's active site [31].

- The Solution: Adjust the binding strength by modulating system parameters like pH and ionic strength, which can shift the interaction and form a dense, liquid-like phase inside the carrier particles to enhance efficiency [31].

Q3: How do we select the optimal ratio of enzymes for a co-immobilized cascade reaction?

A: The optimal ratio is highly specific to your kinetic parameters and should not be extrapolated from individually immobilized enzyme data [28].

- Key Factors: The relationship between the Michaelis constants (

K_M) of the enzymes is critical. Kinetic modeling demonstrates that the greatest advantage for co-immobilization occurs whenK_M2 < K_M1(i.e., the second enzyme has a higher affinity for the intermediate than the first enzyme has for its substrate) [28]. - Design Strategy: Use the time to reach a target yield (rather than just initial reaction rates) to determine the mass ratio for co-immobilized catalysts, as this can lead to a different and more effective optimum [28].

Q4: What are the primary causes of enzyme leaching from the support?

A: Leaching is typically caused by:

- Weak Binding Forces: When relying on physical adsorption or ionic exchange, changes in operational conditions (e.g., ionic strength, pH, solvent polarity) can weaken interactions and cause enzyme release [29] [32].

- Support Degradation: The chemical or mechanical breakdown of the carrier material under process conditions will lead to catalyst loss [30].

- Insufficient Cross-Linking: In carrier-free methods like CLEAs, insufficient cross-linking can result in aggregates that disintegrate during use [33].

Key Experimental Protocols for Creating Self-Sufficient Biocatalysts

Protocol: Synthesis of Co-immobilized Enoate Reductase and Glucose Dehydrogenase via Biomimetic Silicification

This protocol describes a one-pot method for co-immobilizing an enzyme pair to create a self-sufficient system with in-situ cofactor regeneration, based on a study achieving over 44% activity recovery and 92% immobilization efficiency [33].

1. Principle Biomimetic silicification (BI) rapidly encapsulates enzymes within a porous silica network under mild, aqueous conditions. This method co-immobilizes Enoate Reductase (ER) and Glucose Dehydrogenase (GDH), creating a system where GDH regenerates the NAD(P)H cofactor consumed by ER, enabling continuous catalysis [33].

2. Reagents and Equipment

- Enzymes: Enoate Reductase (ER), Glucose Dehydrogenase (GDH)

- Cofactor: NAD(P)+

- Silicic Acid Precursor: e.g., Tetramethyl orthosilicate (TMOS)

- Buffer: Phosphate buffer (e.g., 50 mM, pH 7.0)

- Laboratory Equipment: Microcentrifuge, vortex mixer, thermomixer, spectrophotometer

3. Step-by-Step Procedure

- Preparation: Pre-cool all reagents and equipment to 4°C.

- Enzyme Mixture: In a 1.5 mL microcentrifuge tube, mix ER and GDH in a pre-optimized mass ratio in 1 mL of phosphate buffer (50 mM, pH 7.0).

- Precursor Addition: Add the silicic acid precursor (e.g., TMOS) to the enzyme solution at a final concentration of 50 mM. Vortex immediately for 10-15 seconds to initiate the reaction.

- Particle Formation: Incubate the mixture at 25°C for 30 minutes without agitation. The formation of white ER-GDH-silica particles (ER-GDH-SPs) will be visible.

- Harvesting and Washing: Centrifuge the suspension at 10,000 × g for 5 minutes. Carefully discard the supernatant.

- Washing: Wash the pellet twice with 1 mL of fresh phosphate buffer to remove any unimmobilized enzymes and residual precursor.

- Storage: Suspend the final ER-GDH-SPs in a suitable storage buffer and store at 4°C.

4. Analysis and Characterization

- Activity Recovery: Measure the activity of the free enzyme mixture and the washed ER-GDH-SPs under standard assay conditions. Calculate activity recovery as:

(Activity of ER-GDH-SPs / Activity of free enzyme mixture) × 100%[33] [30]. - Immobilization Efficiency: Determine the protein concentration in the supernatant after immobilization (e.g., via Bradford assay). Calculate efficiency as:

[1 - (Protein in supernatant / Total protein added)] × 100%[30]. - Stability Assessment: Compare the thermal and operational stability (e.g., activity over multiple reaction cycles) of the ER-GDH-SPs against the free enzymes [33].

Protocol: Optimization of Immobilization Conditions using Response Surface Methodology

This protocol outlines a systematic approach to optimize key variables in an immobilization process, such as enzyme ratio, cross-linker concentration, and pH, to maximize yield and stability [34].

1. Experimental Design

- Screening (FFD): Use a Fractional Factorial Design (FFD) to screen multiple factors (e.g., temperature, enzyme concentration, substrate ratio, pH) and identify which have a statistically significant effect on the response (e.g., conversion yield). This narrows down the critical variables for further optimization [34].

- Optimization (CCRD): Apply a Central Composite Rotatable Design (CCRD) to the significant factors identified in the FFD. This design generates a quadratic model that can pinpoint optimal conditions and reveal interaction effects between variables [34].

2. Data Analysis

Analyze the experimental data using statistical software to fit a quadratic polynomial equation (Equation 1):

Y = β₀ + Σβᵢxᵢ + Σβᵢᵢxᵢ² + Σβᵢⱼxᵢxⱼ + ε

Where Y is the response (e.g., yield), β₀ is a constant, βᵢ, βᵢᵢ, and βᵢⱼ are coefficients for linear, quadratic, and interaction effects, and xᵢ, xⱼ are the independent variables [34].

Table 1: Comparison of Co-immobilization Techniques for Cofactor-Dependent Enzymes

| Immobilization Technique | Key Feature | Reported Activity Recovery | Reported Immobilization Efficiency | Advantages | Limitations |

|---|---|---|---|---|---|

| Biomimetic Silicification [33] | One-pot encapsulation in silica particles | 44.5% | 92.4% | Simple, rapid, good stability & reusability | Moderate activity recovery |

| Cross-Linked Enzyme Aggregates (CLEAs) [33] | Carrier-free cross-linked aggregates | 44.9% | 93.5% | High enzyme loading, no expensive carrier | Can be brittle, mass transfer issues |

| Covalent Tethering [32] | Stable covalent bonds to a carrier | Varies by system | Typically high | Very stable, minimal leaching | Can lead to significant activity loss |

| Ionic Adsorption [31] [32] | Electrostatic binding (e.g., using PEI) | Tunable via Sabatier principle | High | Reversible, tunable binding strength | Sensitive to ionic strength and pH |

Table 2: Key Performance Metrics for Industrial Biocatalysts

| Metric | Definition | Industrial Target (Bulk Commodities) | Relevance to Co-immobilization |

|---|---|---|---|

| Total Turnover Number (TTN) [30] | Total moles of product per mole of enzyme over its lifetime | 5 × 10ⵠ– 5 × 10ⶠ| Measures total catalyst lifetime and efficiency; enhanced by stability from co-immobilization. |

| Productivity Number [30] | Mass of product formed per mass of catalyst prepared | ~10â´ kg product / kg catalyst | A practical metric for process economics; high productivity is the ultimate goal of optimization. |

| Immobilization Efficiency [30] | Percentage of enzyme protein successfully bound to the support | Ideally >90% | Indicates the effectiveness of the immobilization process itself. |

| Activity Recovery [33] [30] | Percentage of initial enzymatic activity retained after immobilization | System-dependent; higher is better | Reflects the functional success of immobilization, balancing loading with retained activity. |

Essential Diagrams

Cofactor Recycling via Co-immobilization

Cofactor Recycling Mechanism

Sabatier Principle in Cofactor Binding

Sabatier Principle Application

Co-immobilization Workflow

Experimental Workflow

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Developing Co-immobilized Biocatalysts

| Reagent Category | Specific Examples | Function in Co-immobilization |

|---|---|---|

| Enzyme Classes | Enoate Reductases (ERs), Glucose Dehydrogenase (GDH), Ketoreductases (KREDs), Transaminases [33] [32] | The core catalytic proteins. Selected to work in sequence, where one enzyme often regenerates a cofactor for the other. |

| Essential Cofactors | NAD(P)H, NAD(P)+, Pyridoxal Phosphate (PLP) [32] | Small molecules essential for the activity of many enzymes. Their regeneration in-situ is a primary goal of co-immobilization. |

| Carrier Materials | Agarose beads, Silica nanoparticles, Epoxy resins, Metal-Organic Frameworks (MOFs) [29] [33] [32] | The solid support that provides a high surface area for immobilization, stabilizes enzymes, and allows for catalyst reuse. |

| Cross-linkers & Precursors | Glutaraldehyde, Oxidized Dextran, Tetramethyl orthosilicate (TMOS) [33] | Chemicals used to create covalent bonds between enzyme molecules (in CLEAs) or to form a solid silica matrix (in Biomimetic Silicification). |

| Cationic Polymers | Polyethylenimine (PEI), Diethylaminoethyl (DEAE) [32] | Used to coat carriers, providing a positive charge for the ionic adsorption of negatively charged cofactors (e.g., NAD(P)+), enabling their immobilization [31]. |

| 1-Tetradecanol-d2 | 1-Tetradecanol-d2, MF:C14H30O, MW:216.40 g/mol | Chemical Reagent |

| Tcs 2510 | Tcs 2510, MF:C21H29N5O2, MW:383.5 g/mol | Chemical Reagent |

FAQs: Understanding ATP Regeneration Systems

1. What are the primary advantages and disadvantages of pyruvate kinase-based ATP regeneration?

Pyruvate kinase (PK) uses phosphoenolpyruvate (PEP) as a substrate to regenerate ATP from ADP. Its key advantage is high thermostability and specific activity, leading to efficient ATP recycling. However, a major disadvantage is the high cost and chemical instability of its substrate, PEP. Furthermore, the reaction product, pyruvate, can inhibit some enzymes, potentially interfering with the primary synthetic reaction you are trying to power [35].

2. Why is the acetate kinase system considered cost-effective, and what are its limitations?

The acetate kinase (AcK) system utilizes acetyl phosphate to regenerate ATP. The primary advantage of this system is the low cost of its substrate compared to alternatives like PEP. It can also be integrated with other enzymes, such as pyruvate oxidase and catalase, to create a regeneration pathway from pyruvate. A key limitation is the chemical instability of acetyl phosphate in aqueous solution, which can decompose rapidly and reduce the overall efficiency of the system. Studies have shown that when combined with other systems, like a creatine-based system, it can enhance protein synthesis yield significantly (e.g., up to 78% more product), but its standalone performance may be constrained by substrate stability [36] [35].

3. What makes polyphosphate kinases (PPKs) an attractive option for industrial-scale applications?

Polyphosphate kinases (PPKs), particularly the PPK2 family, use inexpensive, stable, and readily available polyphosphate (PolyP) as a substrate for ATP regeneration [35]. This provides an unrivalled cost advantage for large-scale processes. They can be directly coupled with product-forming enzymes. However, a significant bottleneck is phosphate inhibition; the inorganic phosphate (Pi) released during ATP consumption can inhibit PPK2 activity. For instance, one study found that activity can drop to 50% of the maximum at 50 mM polyphosphate [35]. Additionally, some PPK2 enzymes suffer from poor stability under industrial conditions like high temperature or extreme pH.

4. How can the stability of an ATP regeneration system be improved?

A novel approach to enhance stability is encapsulation within a Virus-Like Particle (VLP). For example, fusing a PPK2 enzyme to the scaffold protein of a P22-VLP creates a protective nanocage. This "armor" has been shown to significantly improve the enzyme's tolerance to high temperature, pH fluctuations, high phosphate concentrations, and proteases compared to the free enzyme, without requiring extensive enzyme engineering [35].

5. My ATP-dependent reaction yield is low, but my regeneration enzyme tests as active. What could be wrong?

Low yield despite active enzymes can stem from several issues:

- Substrate/Product Inhibition: The accumulation of inorganic phosphate (Pi) can strongly inhibit PPK2 enzymes [35].

- Cofactor Diffusion: If the ATP-regenerating enzyme is not well-coupled spatially with the ATP-consuming enzyme, diffusion delays can create local ADP/ATP imbalances, reducing efficiency.

- Unstable Intermediates: Key substrates like acetyl phosphate (for AcK) or PEP (for PK) may be degrading in your reaction buffer.

- Incompatible Buffer Conditions: A high initial phosphate concentration (e.g., ~10 mM) may be necessary for some integrated systems to function, but it could inhibit others. Optimization is required [36].

Troubleshooting Guide for Common Experimental Issues

Problem: Low Product Yield

| Potential Cause | Diagnostic Steps | Recommended Solution |

|---|---|---|

| Phosphate Inhibition | Measure reaction yield at different phosphate concentrations. | For PPK systems, use a VLPs-encapsulated enzyme [35] or increase enzyme concentration. For other systems, ensure phosphate buffer is at required concentration (e.g., ~10 mM) [36]. |

| Unstable Substrate | Test the stability of your key substrate (e.g., acetyl phosphate, PEP) in the reaction buffer over time. | Use freshly prepared substrates. Consider switching to a more stable system (e.g., PolyP-based) or using protective encapsulation [35]. |

| Inefficient Enzyme Coupling | Measure the individual activity of each enzyme in the reaction mixture. | Co-immobilize the ATP-regenerating and ATP-consuming enzymes to create a local high concentration of ATP. The V-CHARGEs system is designed for this purpose [35]. |

| Sub-Optimal Cofactor Ratios | Titrate the ratio of ADP/ATP and substrate (PolyP, acetyl-P, PEP) concentrations. | Systematically optimize the initial concentrations of ADP and the energy substrate. A creatine-based system can be combined with another to boost yield [36]. |

Problem: Poor System Stability Over Time

| Potential Cause | Diagnostic Steps | Recommended Solution |

|---|---|---|

| Enzyme Thermolability | Incubate the enzyme at your reaction temperature and measure residual activity over time. | Use a more thermostable enzyme variant. Alternatively, encapsulate the enzyme in a VLP to enhance thermostability [35]. |

| Proteolytic Degradation | Run an SDS-PAGE gel of the reaction mixture samples over time. | Add protease inhibitors to your reaction mixture. Using a VLP-encapsulated enzyme can confer protease resistance [35]. |

| Chemical Decomposition | Check for a drop in substrate concentration (e.g., acetyl phosphate) without significant product formation. | Source higher-purity substrates, adjust reaction pH, or use a different ATP regeneration system with more stable substrates like polyphosphate [35]. |

Table 1: Performance Comparison of Key ATP Regeneration Systems

| System | Substrate | Cost of Substrate | Key Advantage | Major Limitation | Reported Performance |

|---|---|---|---|---|---|

| Pyruvate Kinase (PK) | Phosphoenolpyruvate (PEP) | High | High specific activity | High cost, substrate instability, product inhibition | N/A |

| Acetate Kinase (AcK) | Acetyl Phosphate | Low | Low-cost substrate | Substrate instability in solution | When combined with creatine system, produced 78% more mCherry protein [36] |

| Creatine Kinase | Phosphocreatine | High | Well-established | High cost, relies on unstable substrate | Baseline for comparison in synergistic studies [36] |

| Polyphosphate Kinase 2 (PPK2) | Polyphosphate (PolyP) | Very Low | Very low cost, high stability of substrate | Strong phosphate inhibition, poor thermostability | 50% activity loss at 50 mM polyphosphate [35] |

| VLP-Encapsulated PPK2 (V-CHARGEs) | Polyphosphate (PolyP) | Very Low | Greatly enhanced stability, resistance to inhibitors | Requires more complex protein engineering | Enhanced stability against heat, pH, phosphate, and proteases [35] |

Table 2: Troubleshooting Solutions and Their Efficacy

| Solution | Applicable System(s) | Implementation Complexity | Key Benefit |

|---|---|---|---|

| Enzyme Co-immobilization | All systems | Medium | Proximity increases local ATP concentration and overall reaction efficiency [35] |

| Substrate Optimization | All systems | Low | Cost-effective; can directly alleviate inhibition or supply issues [36] |

| VLP Encapsulation | PPK2 and other sensitive enzymes | High | Dramatically improves stability against multiple stressors (T°, pH, protease) [35] |

| System Combination | AcK, PK, Creatine Kinase | Medium | Synergistic; can overcome limitations of a single system [36] |

Detailed Experimental Protocols

Protocol: Integrated Pyruvate Oxidase-Acetate Kinase ATP Regeneration

This protocol outlines a method for ATP regeneration that integrates pyruvate oxidase and acetate kinase, as demonstrated to enhance cell-free protein synthesis [36].

Key Reagents:

- Pyruvate oxidase

- Acetate kinase

- Catalase

- Pyruvate

- Inorganic phosphate buffer

- ADP, ATP

Methodology:

- Reaction Setup: Prepare a cell-free reaction mixture containing the core components for your desired synthesis (e.g., transcription/translation machinery for protein synthesis).

- Integration of Regeneration System: To the mixture, add pyruvate oxidase, acetate kinase, and catalase.

- Buffer and Substrates: Use a high initial concentration of phosphate buffer (approximately 10 mM). Provide pyruvate as the primary energy source.

- Initiating the Reaction: Start the reaction by adding ADP and any other necessary cofactors.

- Monitoring: Monitor ATP concentration over time using a luciferase-based assay or HPLC. Quantify the yield of your target end-product (e.g., synthesized protein).

Note: This pathway generates acetyl phosphate from pyruvate, phosphate, and oxygen, which the acetate kinase then uses to rephosphorylate ADP to ATP. The high phosphate concentration is crucial and surprisingly may not inhibit the protein synthesis activity [36].

Protocol: Assembling and Testing a VLP-Encapsulated PPK2 System (V-CHARGEs)

This protocol describes the assembly and validation of a Virus-Like Particle coupled ATP regeneration system, designed to overcome the stability and inhibition issues of free PPK2 enzymes [35].

Key Reagents:

- SlPPK-SP fusion protein: The Sulfurovum lithotrophicum PPK2 fused to the P22-VLP Scaffold Protein.

- CP-SpyTag fusion protein: The P22-VLP Coat Protein fused to SpyTag.

- SpyCatcher-Enzyme fusion protein: Your ATP-consuming enzyme of interest (e.g., Firefly Luciferase, UCK) fused to SpyCatcher.

Methodology:

- VLP Self-Assembly: Co-express or mix the SlPPK-SP and CP-SpyTag fusion proteins in vitro. They will self-assemble into a nanocage with SlPPK anchored inside and SpyTag displayed on the exterior surface.

- Enzyme Anchoring: Incubate the assembled V-CHARGEs with the SpyCatcher-Enzyme fusion. The SpyTag/SpyCatcher interaction will covalently and specifically tether your ATP-consuming enzyme to the outside of the VLP.

- Stability Validation:

- Temperature: Incubate the V-CHARGEs at elevated temperatures (e.g., 60°C) and measure the half-life of the enzymatic activity compared to free SlPPK.

- Phosphate Tolerance: Assay PPK2 activity in the presence of high concentrations of inorganic phosphate (e.g., 50 mM).

- Protease Resistance: Incubate with a non-specific protease and run SDS-PAGE to check for degradation over time.

- Product Validation:

- For a bioluminescence test, add the substrate luciferin to the system and measure light output as evidence of ATP regeneration and consumption.

- For a synthesis test (e.g., of 5'-CMP or Glutathione), quantify product formation using HPLC or a colorimetric assay.

System Workflows and Logical Diagrams

Diagram 1: Three ATP regeneration pathways compared.

Diagram 2: V-CHARGEs structure and ATP regeneration mechanism.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents for ATP Regeneration Experiments

| Item | Function in Research | Key Characteristics |

|---|---|---|

| Polyphosphate (PolyP) | Low-cost substrate for PPK2 enzymes. | Very low cost, high stability, readily available, making it ideal for industrial scale-up [35]. |

| Acetyl Phosphate | Substrate for the acetate kinase (AcK) regeneration system. | Low cost but chemically unstable in aqueous solution, requiring fresh preparation [35]. |

| Phosphoenolpyruvate (PEP) | High-energy phosphate donor for the pyruvate kinase (PK) system. | High specific activity but expensive and chemically unstable, increasing operational costs [35]. |

| P22 Virus-Like Particle (VLP) System | A molecular scaffold to create a protective nanocage for enzymes. | Composed of Coat (CP) and Scaffold (SP) proteins. Used to encapsulate and stabilize PPK2, dramatically improving its resistance to stressors [35]. |

| SpyTag/SpyCatcher System | A protein ligation tool for irreversible, specific coupling. | Used to covalently anchor ATP-consuming enzymes to the exterior of the VLP, creating a multi-enzyme complex for efficient substrate channeling [35]. |

| Firefly Luciferase (FLuc) | A reporter enzyme for validating ATP regeneration. | Catalyzes a light-producing reaction that is directly dependent on ATP, providing a rapid and sensitive readout of ATP availability [35]. |

| Hsp90-IN-31 | Hsp90-IN-31, MF:C22H28N2O4, MW:384.5 g/mol | Chemical Reagent |

| Egfr-IN-54 | Egfr-IN-54, MF:C17H14N4O4S3, MW:434.5 g/mol | Chemical Reagent |

Troubleshooting Common NAD(P)H Recycling Issues

FAQ 1: My NADH oxidase (NOX)-coupled reaction rate is slowing down dramatically. What could be the cause?

A sudden decrease in the reaction rate of an NOX-coupled system is frequently due to oxygen limitation. NOXs use oxygen as the terminal electron acceptor, and its low solubility in aqueous solutions (~0.26 mM at 25°C) often becomes a bottleneck [37].

- Solution: Increase oxygen transfer by sparging the reaction with air or oxygen. However, be aware that this can cause enzyme inactivation at gas-liquid interfaces. As an alternative, consider switching to an oxygen-independent recycling system, such as a soluble hydrogenase (SH). SH systems regenerate NAD+ by oxidizing NADH and releasing H2, bypassing oxygen-related limitations entirely [37].

FAQ 2: I am using a substrate-coupled cofactor regeneration system, but the conversion is low. How can I improve the yield?

Low conversion in substrate-coupled systems (e.g., using an Alcohol Dehydrogenase (ADH) with a sacrificial co-substrate like benzyl alcohol) is often caused by thermodynamic equilibrium or product inhibition [4].

- Solution: Implement a recycling cascade. Design your system so that the co-product from the regeneration step serves as a substrate for another reaction. For instance, the co-product benzaldehyde can be used as a substrate for a previous carboligation step. This "closes the loop," shifts the equilibrium toward product formation, and improves atom economy [4].

FAQ 3: Can I use standard glucose dehydrogenase (GDH) or formate dehydrogenase (FDH) systems to recycle synthetic nicotinamide cofactor analogues?

Typically, no. Standard GDH and FDH are highly specific for their native cofactors (NAD+ or NADP+) and generally show no activity toward synthetic analogues like BNA+ or BAP+ [38].

- Solution: For recycling synthetic cofactor analogues, use enzymes with flavin-active sites that can facilitate electron transfer. Soluble hydrogenases (SH) have been successfully demonstrated to recycle a variety of artificial cofactors with turnover numbers (TON) exceeding 1000 [38].

FAQ 4: Hydrogen peroxide is inhibiting my enzymes in the H2O2-forming NOX system. How can I mitigate this?

H2O2 is a common by-product of certain NOX isoforms and can deactivate other enzymes in your cascade.

- Solution: The most straightforward approach is to select a H2O-forming NOX instead of a H2O2-forming one. If you must use a H2O2-forming NOX, you can add catalase to the reaction mixture. Catalase will convert H2O2 to water and oxygen, thereby protecting your enzyme cascade [37].

Performance Comparison of Cofactor Regeneration Systems

The following table summarizes key performance metrics for different NAD(P)H regeneration systems to aid in selection and troubleshooting.

Table 1: Performance Comparison of Prominent Cofactor Regeneration Systems

| Regeneration System | Principle | Key Advantage | Key Limitation | Reported Performance (TTN/Activity) |

|---|---|---|---|---|

| NADH Oxidase (NOX) | Oxidizes NADH with O2 to regenerate NAD+ [9] | Favorable thermodynamics; widely used [37] | O2-dependent; low O2 solubility can limit rate [37] | TTN up to 44,000 for H2O-forming NOX [37] |

| Soluble Hydrogenase (SH) | Oxidizes NADH, producing H2; also reduces NAD+ with H2 [37] | O2-tolerant; H2 is a clean substrate/by-product [37] [38] | Requires H2 gas handling | TTN up to 44,000 for NAD+ regeneration [37]; >1000 TON for artificial cofactors [38] |

| Glucose Dehydrogenase (GDH) | Oxidizes glucose, reducing NAD(P)+ to NAD(P)H [39] | Cheap substrate; high activity [39] | Cofactor-specific; cannot recycle artificial analogues [38] | Specific activity of 61 U/g (dry cell weight) in permeabilized E. coli [39] |

| Formate Dehydrogenase (FDH) | Oxidizes formate, reducing NAD+ to NADH [2] | Cheap substrate; CO2 by-product easily removed [4] | Low specific activity; cannot recycle artificial analogues [38] | Specific activity of 0.25 U/mg [38] |

| Substrate-Coupled (e.g., ADH) | Same enzyme catalyzes main reaction and cofactor regeneration [4] | Simple system; no additional enzyme needed [4] | Thermodynamic equilibrium can limit yield; co-product accumulates [4] | >100 mM product concentration achieved in cascades with co-product recycling [4] |

Experimental Protocols for Key Methodologies

Protocol: H2-Driven Cofactor Recycling with Soluble Hydrogenase

This protocol describes the use of a soluble hydrogenase (SH) for O2-independent, H2-driven recycling of NAD+ or synthetic cofactor analogues, coupled with a dehydrogenase [38] [37].

- Reaction Setup: Prepare a reaction mixture containing:

- Buffer: 50 mM MOPS-NaOH, pH 7.0 (for ReSH) or 50 mM Tris-HCl, pH 8.0 (for HtSH).

- Cofactor: 2 mM NAD+ or synthetic analogue (e.g., BAP+).

- Flavin Mononucleotide (FMN): 0.1 mM (significantly boosts SH activity).

- Dehydrogenase: A suitable amount of your target dehydrogenase (e.g., Xylose Dehydrogenase).

- Substrate: The specific substrate for your dehydrogenase.

- Catalase: As a precaution against any potential H2O2 formation.

- Soluble Hydrogenase (SH): 40 µg (e.g., from Ralstonia eutropha or Hydrogenophilus thermoluteolus).

- H2 Saturation: Seal the reaction vial and saturate the headspace with H2 gas. Maintain a slight H2 overpressure throughout the reaction, either by continuous bubbling or in a sealed, H2-filled environment [38].

- Incubation: Incubate the reaction at the optimal temperature for the SH (e.g., 32°C for ReSH, 50°C for HtSH) with mixing [38].

- Monitoring: Monitor cofactor reduction or substrate consumption/product formation via UV-Vis spectroscopy or other suitable analytical methods (e.g., GC, HPLC).

Protocol: Two-Step Cofactor and Co-Product Recycling Cascade

This protocol outlines a cascade for diol synthesis where the co-product from the ADH step is recycled as a substrate for the first step, minimizing waste and shifting equilibrium [4].

- Enzyme Preparation: Use a ThDP-dependent carboligase (e.g., Benzaldehyde lyase from Pseudomonas fluorescens, PfBAL) and an Alcohol Dehydrogenase (e.g., from Ralstonia sp., RADH).

- One-Pot Reaction: Combine in a single reaction vessel:

- Buffer: Tris-HCl or TEA-HCl buffer, pH 9.0 (optimized for RADH reduction).

- Cofactor: NADP+.

- Substrates: Acetaldehyde and a high concentration of benzyl alcohol (e.g., 250 mM). Note: Benzaldehyde is not added initially; it is generated in situ.

- Enzymes: PfBAL and a sufficient concentration of RADH (e.g., 0.30 mg/mL).

- Reaction Mechanism:

- Step 1 (Carboligation): PfBAL catalyzes the reaction between acetaldehyde and the in-situ generated benzaldehyde to form (R)-2-hydroxy-1-phenylpropan-1-one ((R)-2-HPP).

- Step 2 (Reduction & Regeneration): RADH reduces (R)-2-HPP to (1R,2R)-1-phenylpropane-1,2-diol (PPD). The NADPH formed is regenerated by RADH oxidizing benzyl alcohol to benzaldehyde, which is then consumed by PfBAL in Step 1.

- Incubation: Incubate at 30°C with agitation.

- Analysis: Monitor diol formation using chiral GC or HPLC. This system can achieve >100 mM product concentration with high optical purity (ee, de >99%) [4].

System Workflow and Logical Diagrams

NAD(P)+ Recycling System Logic

Two-Step Recycling Cascade Workflow

Research Reagent Solutions

Table 2: Key Reagents for NAD(P)H Recycling Methodologies

| Reagent / Enzyme | Primary Function in Recycling | Key Considerations for Use |

|---|---|---|

| Soluble Hydrogenase (SH) | H2-driven oxidation/reduction of NAD+/NADH and synthetic analogues [38] [37] | O2-tolerant; requires H2 gas supply; effective for artificial cofactors [38]. |

| NADH Oxidase (NOX) | Regenerates NAD+ by oxidizing NADH using O2 [9] | Select H2O-forming isoforms to avoid H2O2 inhibition; monitor O2 supply [37] [9]. |

| Glucose Dehydrogenase (GDH) | Regenerates NAD(P)H by oxidizing glucose [39] | Inexpensive substrate; high activity; not suitable for artificial cofactors [39] [38]. |

| Alcohol Dehydrogenase (ADH) | Used in substrate-coupled regeneration; oxidizes co-substrate (e.g., benzyl alcohol) [4] | Can be designed into recycling cascades to consume co-product [4]. |

| Formate Dehydrogenase (FDH) | Regenerates NADH by oxidizing formate [2] | CO2 by-product easily removes itself; low activity; not for artificial cofactors [4] [38]. |

| Synthetic Cofactor Analogues (e.g., BNA+, BAP+) | Lower-cost, often more stable alternatives to NAD(P)H [38] | Cannot be recycled by standard GDH/FDH; require specific enzymes like SH [38]. |

In continuous flow biocatalysis, maintaining the activity of enzymes and retaining essential cofactors like NAD(P)+, PLP, and ATP within the reactor is a fundamental challenge and key to process economics. Cofactors are non-protein compounds required for the catalytic activity of many enzymes but are often expensive and consumed stoichiometrically. Continuous flow bioreactors address this through advanced immobilization and reactor engineering strategies that prevent cofactor leaching while enhancing operational stability. These systems transform batch processes into efficient continuous operations, enabling higher productivity, better control, and significant cost reduction by allowing cofactors to be reused for thousands of turnover cycles.

The transition to continuous flow systems represents a paradigm shift in biocatalysis, particularly for pharmaceutical synthesis and the production of value-added chemicals. Unlike traditional batch reactors, where enzymes and cofactors are used once or require separate regeneration systems, integrated continuous systems co-immobilize both the enzyme and its cofactor within a confined space. This approach maintains optimal reaction conditions, minimizes reagent consumption, and allows for prolonged operation over days or weeks. The following sections provide a comprehensive technical support framework for researchers developing these sophisticated bioprocesses.

Troubleshooting Common Operational Issues

| Problem Category | Specific Symptom | Potential Cause | Solution | Reference |

|---|---|---|---|---|

| Cofactor Leaching | ➤ Activity declines rapidly over time, even with stable enzyme.➤ Cofactor detected in effluent stream. | ➤ Ineffective cofactor immobilization method.➤ Weak electrostatic interaction or physical entrapment.➤ Pore size too large for cofactor retention. | ➤ Use polyethylenimine (PEI) to create electrostatic bonds with PLP. [40]➤ Employ hydrogel polymers (PVA-alginate) for dense physical entrapment. [40]➤ Implement covalent conjugation strategies. | |