A Comprehensive Guide to RT-qPCR for Biosynthetic Gene Analysis: From Fundamentals to Advanced Validation in Drug Discovery

This article provides a complete methodological framework for utilizing Reverse Transcription Quantitative Polymerase Chain Reaction (RT-qPCR) in the analysis of biosynthetic gene expression.

A Comprehensive Guide to RT-qPCR for Biosynthetic Gene Analysis: From Fundamentals to Advanced Validation in Drug Discovery

Abstract

This article provides a complete methodological framework for utilizing Reverse Transcription Quantitative Polymerase Chain Reaction (RT-qPCR) in the analysis of biosynthetic gene expression. Aimed at researchers and drug development professionals, it covers foundational principles, detailed protocols for application in metabolic engineering and pathway elucidation, solutions for common experimental pitfalls, and rigorous validation strategies. By integrating current best practices and comparative insights, this guide empowers scientists to generate robust, quantitative gene expression data critical for advancing natural product discovery and biotherapeutic development.

Understanding RT-qPCR: The Gold Standard for Quantifying Biosynthetic Pathway Expression

The Central Role of Gene Expression in Biosynthetic Pathway Engineering

Application Notes: Integrating RT-qPCR into Pathway Engineering Workflows

RT-qPCR is the cornerstone quantitative method for analyzing gene expression dynamics in engineered biosynthetic pathways. It enables the precise correlation between transcriptional activity of pathway genes and final titers of target compounds (e.g., pharmaceuticals, biofuels). The following application notes detail its implementation.

Key Application 1: Pathway Bottleneck Identification

Simultaneous quantification of all genes within an engineered operon or cluster reveals rate-limiting enzymatic steps. A fold-change in gene expression under different promoters or culture conditions directly informs iterative engineering strategies.

Key Application 2: Host Strain Optimization

RT-qPCR assays for host metabolic burden markers (e.g., stress response genes) alongside pathway genes allow for balancing heterologous expression with host viability, maximizing yield.

Key Application 3: Fermentation Process Monitoring

Tracking gene expression profiles across fermentation time courses using RT-qPCR provides real-time, mechanistic insights into pathway performance, guiding feed strategies and harvest timing.

Protocols

Protocol 1: RT-qPCR for Multi-Gene Pathway Analysis

Objective: Quantify expression of all genes in an engineered taxadiene biosynthetic pathway in Saccharomyces cerevisiae.

Materials & Reagents:

- Strain: S. cerevisiae engineered with pTAR plasmid expressing GGPS, TS, T5αH genes.

- Culture: 50 mL YPD + antibiotic in 250 mL flask.

- RNA Stabilization: RNAlater Solution.

- Cell Lysis: Zymolyase-20T.

- RNA Extraction: RNeasy Mini Kit (Qiagen) with on-column DNase I digest.

- cDNA Synthesis: High-Capacity cDNA Reverse Transcription Kit (Applied Biosystems) with random hexamers.

- qPCR: PowerUp SYBR Green Master Mix (Applied Biosystems), validated primer pairs for each pathway gene and reference genes (ACT1, TAF10).

- Instrument: Applied Biosystems 7500 Fast Real-Time PCR System.

Procedure:

- Sampling: Harvest 5 mL culture at mid-log phase (OD600 ~10). Immediately mix with 1 vol RNAlater. Pellet cells.

- RNA Extraction: Resuspend in buffer with Zymolyase, incubate 30 min at 30°C. Proceed with RNeasy kit protocol. Elute in 30 µL RNase-free water. Assess purity (A260/A280 ~2.0) and integrity (Bioanalyzer RIN >8.0).

- DNase Treatment: Perform on-column digestion per kit instructions.

- cDNA Synthesis: Use 1 µg total RNA in 20 µL reaction. Conditions: 25°C for 10 min, 37°C for 120 min, 85°C for 5 min.

- qPCR Setup: Prepare 20 µL reactions in triplicate: 10 µL SYBR Green Mix, 0.8 µL each primer (10 µM), 2 µL cDNA (diluted 1:10), 6.4 µL H2O. Include no-template controls.

- Thermocycling: 50°C for 2 min; 95°C for 2 min; 40 cycles of 95°C for 15 sec, 60°C for 1 min; followed by melt curve.

- Data Analysis: Use the comparative Cq (ΔΔCq) method. Normalize target gene Cq to the geometric mean of reference gene Cqs. Calculate fold-change relative to control strain.

Table 1: Representative RT-qPCR Data for Taxadiene Pathway Genes

| Gene | Function | Cq (Mean ± SD) | Normalized Expression (ΔCq) | Fold-Change vs. Weak Promoter |

|---|---|---|---|---|

| GGPS | Geranylgeranyl diphosphate synthase | 22.3 ± 0.2 | 5.1 | 34.5 |

| TS | Taxadiene synthase | 19.8 ± 0.3 | 2.6 | 6.0 |

| T5αH | Taxadiene 5α-hydroxylase | 25.1 ± 0.4 | 7.9 | 240.1 |

| ACT1 | Reference | 17.2 ± 0.1 | - | - |

| TAF10 | Reference | 20.5 ± 0.2 | - | - |

Protocol 2: Time-Course Fermentation Monitoring

Objective: Monitor expression of amorpha-4,11-diene synthase (ADS) gene in E. coli over a 48-hour fermentation.

Procedure:

- Fermentation: Use a 2 L bioreactor with controlled pH (7.0) and DO. Induce pathway with IPTG at OD600 0.6.

- Sampling: Aseptically remove 3 mL aliquots at T=0, 2, 4, 8, 12, 24, 48h post-induction. Process immediately for RNA.

- Analysis: Follow RNA extraction and RT-qPCR steps from Protocol 1 for ADS and reference gene rpoD. Correlate ADS expression with LC-MS measurements of amorpha-4,11-diene titer.

Table 2: Time-Course Expression of ADS vs. Product Titer

| Time Post-Induction (h) | Normalized ADS Expression (ΔCq) | Amorpha-4,11-diene Titer (mg/L) |

|---|---|---|

| 0 | 0.0 (Baseline) | 0.5 |

| 2 | 5.2 | 15.2 |

| 4 | 7.1 | 82.5 |

| 8 | 6.8 | 305.7 |

| 12 | 5.5 | 510.3 |

| 24 | 3.1 | 880.9 |

| 48 | 1.8 | 950.1 |

Visualizations

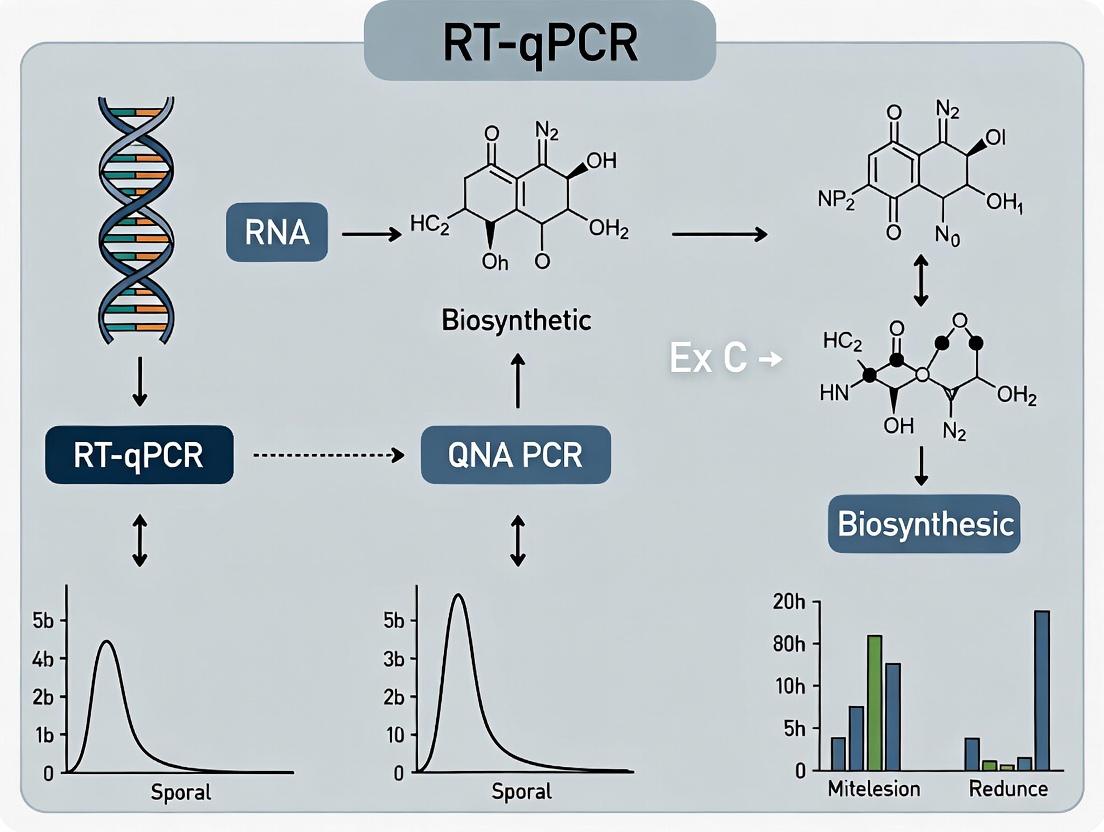

Diagram 1: RT-qPCR Feedback Loop for Pathway Engineering

Diagram 2: RT-qPCR Monitoring of a Terpenoid Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Gene Expression-Driven Pathway Engineering

| Reagent/Category | Example Product(s) | Key Function in Workflow |

|---|---|---|

| RNA Stabilizer | RNAlater Solution, RNAprotect Bacteria Reagent | Immediately stabilizes cellular RNA at harvest, preventing degradation and ensuring accurate expression profiles. |

| Robust RNA Extraction Kit | RNeasy Mini/Midi Kits (Qiagen), Monarch Total RNA Miniprep Kit (NEB) | Purifies high-quality, DNA-free RNA from challenging microbial or fungal matrices. |

| Genomic DNA Elimination | DNase I (RNase-free), On-column digestion protocols | Critical for removing contaminating gDNA to prevent false positives in RT-qPCR. |

| High-Fidelity Reverse Transcriptase | SuperScript IV, High-Capacity cDNA Kit | Ensures efficient and representative cDNA synthesis from full-length mRNA templates. |

| qPCR Master Mix | PowerUp SYBR Green, TaqMan Fast Advanced Master Mix | Provides sensitive, specific detection with minimal optimization. Probe-based mixes enhance specificity for homologous genes. |

| Validated Primer Pairs | Custom-designed with tools like Primer-BLAST; pre-validated reference gene assays | Ensures specific, efficient amplification of each pathway gene and stable reference genes (e.g., rpoD, ACT1). |

| Quantification Standards | Synthetic gBlocks Gene Fragments, Dilution series for absolute quantification | Enables absolute copy number determination of transcripts for metabolic flux modeling. |

Within the context of biosynthetic gene expression analysis for drug development, Reverse Transcription Quantitative Polymerase Chain Reaction (RT-qPCR) remains the gold standard for precise, sensitive quantification of target transcripts. This application note details the core principles—reverse transcription, amplification, and real-time detection—that enable the conversion of RNA into robust quantitative data, critical for elucidating gene function in metabolic engineering and therapeutic target validation.

RT-qPCR quantifies RNA by monitoring the accumulation of fluorescently labeled PCR products during each cycle of amplification. The key quantitative output is the Cycle Threshold (CT), the cycle number at which the fluorescent signal crosses a defined threshold above background. The CT value is inversely proportional to the starting amount of target nucleic acid.

Key Quantitative Metrics

Table 1: Core Quantitative Outputs of RT-qPCR Analysis

| Metric | Definition | Interpretation in Biosynthetic Pathway Analysis |

|---|---|---|

| CT (Cycle Threshold) | Cycle number where fluorescence exceeds threshold. | Lower CT = higher initial target RNA concentration. |

| ΔCT | CT(Target Gene) - CT(Reference Gene). | Normalized expression level of the target gene. |

| ΔΔCT | ΔCT(Test Sample) - ΔCT(Calibrator Sample). | Fold-change in gene expression relative to a control. |

| Amplification Efficiency (E) | Efficiency of PCR reaction per cycle. E=10(-1/slope) -1. | Ideal E=1 (100%). Critical for accurate fold-change calculation. |

| Dynamic Range | Range of template concentrations over which quantification is linear. | Typically spans 6-8 orders of magnitude for target detection. |

Core Principles & Workflow

Diagram 1: RT-qPCR core workflow from RNA to data.

Principle 1: Reverse Transcription (RT)

This step converts RNA into complementary DNA (cDNA) using a reverse transcriptase enzyme.

Detailed Protocol: Two-Step RT Reaction

- RNA Prerequisites: Use 10 pg – 1 µg of high-quality, DNase-treated total RNA in nuclease-free water. Assess integrity via RIN (RNA Integrity Number) >7.0.

- Priming: Combine in a thin-walled tube:

- RNA template: 1 µg (variable).

- Oligo(dT)18, Random Hexamers, or Gene-Specific Primer: 50 pmol (select based on application).

- dNTP Mix: 1 mM final concentration.

- Nuclease-free water to 13 µL.

- Denaturation & Annealing: Heat mixture to 65°C for 5 min, then immediately chill on ice for 2 min.

- Master Mix: Add 7 µL of a prepared mix containing:

- 5X Reaction Buffer: 4 µL.

- RNase Inhibitor (20 U/µL): 1 µL.

- Reverse Transcriptase (200 U/µL): 1 µL.

- DTT (0.1 M): 1 µL (if required).

- Incubation: Run the 20 µL reaction: 25°C for 5 min (primer annealing), 50°C for 45-60 min (extension), 70°C for 15 min (enzyme inactivation). Hold at 4°C. cDNA can be stored at -20°C.

Principle 2: Quantitative PCR (qPCR) Amplification

The cDNA is amplified with sequence-specific primers, and fluorescence is monitored each cycle.

Detailed Protocol: SYBR Green qPCR Setup

- Reaction Assembly (20 µL):

- 2X SYBR Green Master Mix: 10 µL (contains hot-start Taq polymerase, dNTPs, buffer, SYBR Green I dye, MgCl2).

- Forward Primer (10 µM): 0.8 µL.

- Reverse Primer (10 µM): 0.8 µL.

- cDNA template: 2 µL (typically a 1:5 to 1:20 dilution of RT product).

- Nuclease-free water: 6.4 µL.

- Cycling Parameters (Standard Instrument):

- Initial Denaturation: 95°C for 3 min (1 cycle).

- Amplification: 95°C for 15 sec, 60°C for 60 sec (40-45 cycles). Fluorescence acquisition at the end of each 60°C step.

- Melt Curve Analysis: 95°C for 15 sec, 60°C for 60 sec, then gradual increase to 95°C (+0.3°C/sec) with continuous fluorescence measurement.

Principle 3: Real-Time Detection & Quantification

Fluorescence increase is proportional to PCR product mass. Data analysis converts CT into biological insights.

Diagram 2: The four-step data analysis pathway.

Protocol: Absolute Quantification via Standard Curve

- Standard Preparation: Prepare a 10-fold serial dilution (e.g., 106 to 101 copies/µL) of a plasmid or gBlock containing the target sequence.

- Run qPCR: Amplify standard dilutions and unknown samples on the same plate.

- Generate Curve: Plot the CT value of each standard against the log10 of its starting quantity. The slope indicates efficiency: Efficiency % = (10(-1/slope) - 1) x 100.

- Interpolate Unknowns: Use the linear regression equation from the standard curve to calculate the starting quantity of the target in each unknown sample.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for RT-qPCR in Gene Expression Analysis

| Reagent Category | Specific Example | Critical Function |

|---|---|---|

| RNA Isolation | Silica-membrane spin columns with DNase I treatment. | Purifies intact, DNA-free total RNA from complex biological samples (cells, tissues). |

| Reverse Transcriptase | Moloney Murine Leukemia Virus (M-MLV) or engineered derivatives (e.g., Superscript IV). | Synthesizes stable cDNA from RNA template with high fidelity and yield. |

| qPCR Master Mix | SYBR Green or TaqMan probe-based mixes (2X concentration). | Contains all core components (polymerase, dNTPs, buffer, dye) for robust, sensitive amplification. |

| Assay Design | Validated primer pairs or hydrolysis probes. | Ensures specific, efficient amplification of the target cDNA sequence. |

| Reference Genes | Primer sets for genes like GAPDH, ACTB, HPRT1, or 18S rRNA (validated for system). | Controls for technical variation (RNA input, cDNA synthesis efficiency) for accurate ΔCT calculation. |

| Nuclease-Free Water | DEPC-treated or ultrapure filtered water. | Solvent for all reactions; prevents degradation of RNA and enzymatic components. |

| Quantification Standard | Synthetic oligonucleotide (gBlock) or linearized plasmid DNA. | Enables absolute quantification by providing a known-copy-number standard for curve generation. |

Within the broader thesis on RT-qPCR for biosynthetic gene expression analysis, this application note details how the technique's core advantages—sensitivity, specificity, and throughput—directly empower biosynthesis research. These attributes enable precise quantification of low-abundance biosynthetic gene transcripts, discrimination between closely related gene family members, and high-sample-capacity screening for pathway engineering.

Comparative Advantage Data

Table 1: Quantitative Performance Metrics of RT-qPCR in Biosynthesis Studies

| Advantage | Metric | Typical Performance Range | Impact on Biosynthesis Research |

|---|---|---|---|

| Sensitivity | Detection Limit | 1-10 copies of target RNA | Enables study of lowly expressed regulatory & pathway genes. |

| Specificity | Amplicon Discrimination | Single-nucleotide mismatch detection (with optimized probe design) | Distinguishes between paralogous genes in biosynthetic clusters. |

| Throughput | Samples per Run | 96- or 384-well plates (≤384 samples/run) | Screen mutant libraries or time-course inductions efficiently. |

Table 2: Comparison of Gene Expression Methods for Biosynthetic Pathway Analysis

| Method | Sensitivity | Specificity | Throughput | Best for Biosynthesis Application |

|---|---|---|---|---|

| RT-qPCR | Very High | Very High | High | Definitive quantification of key pathway gene expression. |

| Microarray | Moderate | Moderate | High | Initial screening of pathway regulation across genome. |

| RNA-Seq | High | High | Moderate | Discovery of novel genes within biosynthetic clusters. |

| Northern Blot | Low-Moderate | High | Low | Historical validation of transcript size. |

Detailed Protocols

Protocol 1: High-Sensitivity RT-qPCR for Low-Abundance Transcripts

Application: Quantifying expression of rare transcriptional regulators (e.g., TetR-family repressors) controlling biosynthesis. Workflow:

- RNA Isolation: Use a column-based kit with DNase I treatment. Elute in 30 µL RNase-free water. Assess integrity (RIN > 8.5).

- Reverse Transcription: Use a High-Capacity cDNA Reverse Transcription Kit.

- Combine: 1 µg total RNA, 2 µL 10X RT Buffer, 0.8 µL 25X dNTP Mix (100 mM), 2 µL 10X RT Random Primers, 1 µL MultiScribe Reverse Transcriptase, nuclease-free H₂O to 20 µL.

- Cycle: 25°C for 10 min, 37°C for 120 min, 85°C for 5 min. Hold at 4°C.

- qPCR Setup (20 µL Reaction):

- Master Mix: 10 µL 2X TaqMan Gene Expression Master Mix, 1 µL 20X TaqMan Assay (FAM-labeled), 4 µL nuclease-free H₂O.

- Combine 15 µL Master Mix with 5 µL cDNA (diluted 1:10). Run in triplicate.

- qPCR Cycling: 50°C for 2 min, 95°C for 10 min; 40 cycles of 95°C for 15 sec and 60°C for 1 min.

- Analysis: Use the comparative Cq (ΔΔCq) method. Normalize to housekeeping gene (e.g., rpoB).

Diagram Title: High-Sensitivity RT-qPCR Workflow

Protocol 2: High-Specificity Assay for Gene Family Discrimination

Application: Differentiating expression of polyketide synthase (PKS) module paralogs. Workflow:

- Primer/Probe Design: Align target gene sequences. Design primers and TaqMan MGB probes across a region of maximal divergence. Place the probe over a unique SNP. Verify specificity in silico.

- cDNA Synthesis: As in Protocol 1, but use gene-specific primers for reverse transcription if necessary.

- Specificity Validation: Run qPCR reactions (as in Protocol 1, Step 3) using the designed assay against cDNA from a strain expressing only the target paralog and cDNA from a strain expressing other paralogs. Confirm amplification only in the target sample.

- Quantitative Experiment: Proceed with experimental sample analysis using the validated assay.

Diagram Title: High-Specificity Assay Design Path

Protocol 3: High-Throughput Screening of Induced Pathways

Application: Screening a library of microbial mutants for altered expression of a target biosynthetic gene cluster. Workflow:

- Culture & Induction: Grow 96-deep-well plate cultures. Induce with elicitor. Harvest cells by centrifugation.

- Automated Nucleic Acid Prep: Use a robotic liquid handler for high-throughput RNA extraction and DNase treatment.

- Automated cDNA Synthesis: Use the handler to set up reverse transcription in 96-well format.

- High-Density qPCR: Dilute cDNA and combine with TaqMan Fast Advanced Master Mix. Use a 384-well qPCR plate. Load with automated pipettor.

- Data Processing: Use qPCR instrument software to automate baseline/threshold setting. Export Cq values for analysis with statistical software (e.g., R) to identify hits.

Diagram Title: High-Throughput Screening Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for RT-qPCR in Biosynthesis Studies

| Item | Function in Biosynthesis Research | Example Product(s) |

|---|---|---|

| High-Fidelity RNA Isolation Kit | Obtains intact RNA from complex microbial/plant tissues; critical for long biosynthetic gene transcripts. | RNeasy Mini Kit, Direct-zol RNA Miniprep |

| DNase I, RNase-free | Eliminates genomic DNA contamination, preventing false positives from biosynthetic gene clusters. | Turbo DNase, DNase I (RNase-free) |

| High-Capacity RT Kit | Maximizes cDNA yield from precious samples (e.g., rare mutant isolates or slow-growing strains). | High-Capacity cDNA Reverse Transcription Kit |

| TaqMan Gene Expression Assays | Provides pre-validated, high-specificity primer/probe sets for conserved model system genes (normalizers). | TaqMan Assays for gapdh, rpoB, act1 |

| TaqMan Fast Advanced Master Mix | Enables rapid cycling for high-throughput screening without sacrificing sensitivity. | TaqMan Fast Advanced Master Mix |

| Custom TaqMan MGB Probe | Enables discrimination of single nucleotide variants in highly conserved biosynthetic genes. | Custom TaqMan MGB Probe Design |

| Automated Liquid Handler | Enables reproducible setup of 96/384-well reactions for screening mutant libraries. | EpMotion, Bravo NGS工作站 |

| qPCR Plates & Seals | Ensure optimal thermal conductivity and prevent cross-contamination in high-density runs. | MicroAmp Optical 384-Well Plate, Optical Adhesive Film |

Within the context of a broader thesis on RT-qPCR for biosynthetic gene expression analysis in drug discovery, the precise function and optimization of core components are critical. This document details application notes and protocols for these essential elements, enabling reliable quantification of low-abundance transcripts from biosynthetic pathways.

Research Reagent Solutions & Essential Materials

The following table lists key reagents and materials required for robust RT-qPCR experiments targeting biosynthetic genes.

| Component | Function & Rationale |

|---|---|

| Sequence-Specific Primers | Designed to flank the target cDNA amplicon (80-150 bp). Critical for specific amplification of target biosynthetic gene family members (e.g., PKS, NRPS). |

| Hydrolysis Probes (TaqMan) | Dual-labeled (fluorophore/quencher) oligonucleotides provide sequence-specific detection, enhancing specificity and enabling multiplexing in complex samples. |

| High-Efficiency Reverse Transcriptase | Converts mRNA to cDNA. Must process high GC-content transcripts and secondary structures common in biosynthetic gene clusters. |

| RNase Inhibitor | Protects RNA integrity during reverse transcription, essential for analyzing labile transcripts. |

| dNTP Mix | Deoxynucleotide triphosphates (dATP, dCTP, dGTP, dTTP) are the building blocks for cDNA synthesis and PCR amplification. |

| Thermostable DNA Polymerase | Enzyme for the qPCR amplification step, often combined with uracil-DNA glycosylase (UDG) for carryover prevention. |

| Optimized Buffer Systems | Provide optimal ionic conditions (Mg2+, K+) and stabilizers for both reverse transcription and PCR efficiency. |

| Nuclease-Free Water | Solvent to prevent degradation of RNA and enzymatic reactions. |

Component Specifications & Quantitative Data

Table 1: Primer and Probe Design Parameters

| Parameter | Optimal Specification | Rationale |

|---|---|---|

| Amplicon Length | 80-150 base pairs | Ensures high amplification efficiency within the qPCR kinetics phase. |

| Primer Length | 18-22 nucleotides | Balances specificity and annealing efficiency. |

| Tm (Primers) | 58-60°C, <2°C difference | Uniform annealing for both primers. |

| GC Content | 40-60% | Stable primer-template binding; avoids secondary structures. |

| 3' End Sequence | Avoid 3+ G/C clamps | Prevents mispriming and non-specific amplification. |

| Probe Tm | 8-10°C higher than primers | Ensures probe hybridizes before primer extension. |

Table 2: Reverse Transcriptase Performance Comparison

| Enzyme Type | Processivity | Thermal Stability | Recommended Input RNA | Best For |

|---|---|---|---|---|

| MMLV-derived | High | Moderate (37-42°C) | 1 pg – 1 µg | Standard reactions, high yield. |

| Engineered MMLV | Very High | High (up to 55°C) | 100 pg – 2 µg | GC-rich templates, secondary structures. |

| ArrayScript | Moderate | High (50°C) | 10 pg – 1 µg | Sensitive detection of low-abundance transcripts. |

Detailed Experimental Protocols

Protocol 1: Two-Step RT-qPCR for Biosynthetic Gene Expression Analysis

Objective: To quantitatively assess the expression of a polyketide synthase (PKS) gene in a bacterial fermentation sample relative to a housekeeping gene.

Part A: cDNA Synthesis (Reverse Transcription)

- Template Preparation: Use 1 µg of total RNA (DNase I-treated) in 13 µL of nuclease-free water.

- Master Mix Assembly: On ice, combine for each reaction:

- 4 µL 5X RT Buffer (provided with enzyme)

- 1 µL dNTP Mix (10 mM each)

- 1 µL Gene-Specific Reverse Primer or Random Hexamers (50 µM)

- 0.5 µL RNase Inhibitor (40 U/µL)

- 1 µL High-Efficiency Reverse Transcriptase (200 U/µL)

- Incubation: Add 7.5 µL Master Mix to 13 µL RNA. Mix gently.

- Primer Annealing: 25°C for 10 min.

- cDNA Synthesis: 50°C for 60 min.

- Enzyme Inactivation: 85°C for 5 min.

- Product: Dilute cDNA 1:5 with nuclease-free water before qPCR.

Part B: Quantitative PCR (qPCR)

- Reaction Assembly: In a 96-well optical plate, prepare 20 µL reactions per sample in duplicate:

- 10 µL 2X Probe-based qPCR Master Mix

- 1.8 µL Forward Primer (10 µM)

- 1.8 µL Reverse Primer (10 µM)

- 0.5 µL Hydrolysis Probe (10 µM)

- 5 µL Diluted cDNA Template

- 0.9 µL Nuclease-Free Water

- Thermal Cycling (in a calibrated thermal cycler):

- UDG Incubation (Optional): 50°C for 2 min.

- Initial Denaturation: 95°C for 10 min.

- 40 Cycles of:

- Denature: 95°C for 15 sec.

- Anneal/Extend: 60°C for 60 sec (collect fluorescence).

- Data Analysis: Use the comparative Cq (ΔΔCq) method. Normalize PKS gene Cq values to the housekeeping gene and calculate fold-change relative to the control sample.

Protocol 2: One-Step RT-qPCR for High-Throughput Screening

Objective: Rapid screening of fungal cultures for induction of a non-ribosomal peptide synthetase (NRPS) gene.

- Reaction Setup: Combine in a single tube:

- 5 µL 2X One-Step RT-qPCR Buffer

- 0.4 µL Forward Primer (10 µM)

- 0.4 µL Reverse Primer (10 µM)

- 0.2 µL Probe (10 µM)

- 0.5 µL RT Enzyme Mix / Hot Start DNA Polymerase

- X µL RNA Template (up to 100 ng)

- Nuclease-free water to 10 µL.

- Thermal Cycling:

- Reverse Transcription: 50°C for 15 min.

- Polymerase Activation: 95°C for 10 min.

- 45 Cycles: 95°C for 15 sec, 60°C for 60 sec (collect fluorescence).

Visualized Workflows and Pathways

Two-Step RT-qPCR Workflow for Gene Expression

Primer and Probe Function in qPCR Detection

From Signal to mRNA Quantification in BGC Research

In RT-qPCR-based research on biosynthetic gene clusters (BGCs), precise quantification of gene expression is paramount. The critical outputs—Ct values, amplification efficiency (E), and dynamic range—form the foundational triad for reliable data interpretation. Accurate determination of these parameters directly impacts conclusions about pathway regulation, metabolic engineering efficacy, and drug candidate prioritization.

Defining and Interpreting the Critical Outputs

Cycle Threshold (Ct) Value

The Ct value is the cycle number at which the fluorescent signal of a qPCR reaction crosses a defined threshold above background. It is a primary quantitative measure, inversely proportional to the starting template amount.

Key Considerations:

- Reproducibility: Low intra- and inter-assay variation (< 0.5 cycles) is essential for comparative analysis.

- Threshold Setting: Should be placed in the exponential phase of amplification, typically using the software's automated function applied consistently across all runs.

- Limit of Detection (LoD): Typically, a Ct value > 35-40 (depending on assay optimization) is considered uncertain.

Amplification Efficiency (E)

Amplification efficiency represents the fractional increase in amplicon per cycle during the exponential phase. An ideal reaction has an efficiency of 100% (E=2.0, meaning product doubles each cycle). It is calculated from the slope of the standard curve.

Calculation: ( E = 10^{-1/slope} - 1 ) A slope of -3.32 corresponds to 100% efficiency.

Dynamic Range

The dynamic range is the span of template concentrations over which the assay provides linear and accurate quantification, typically defined by a serial dilution standard curve. It is crucial for analyzing genes with vastly different expression levels within a biosynthetic pathway.

Table 1: Acceptable Ranges for Critical Outputs in Validated RT-qPCR Assays

| Parameter | Optimal Value / Range | Acceptable Range | Method of Determination |

|---|---|---|---|

| Amplification Efficiency (E) | 90–105% (1.90–2.05) | 80–110% | Standard curve slope |

| Standard Curve R² | ≥ 0.995 | ≥ 0.990 | Linear regression |

| Dynamic Range | ≥ 6 orders of magnitude* | ≥ 5 orders of magnitude | Serial dilution linearity |

| Inter-Assay CV for Ct | < 1.5% | < 2.5% | Replicate standard curves |

| Intra-Assay CV for Ct | < 1.0% | < 1.5% | Technical replicates |

*e.g., from 10^1 to 10^7 copies.

Table 2: Impact of Suboptimal Critical Outputs on Gene Expression Data

| Suboptimal Parameter | Effect on Relative Quantification (ΔΔCt) | Consequence for BGC Analysis |

|---|---|---|

| Low Efficiency (<80%) | Underestimates high Ct (low abundance) targets | Misrepresents expression of regulatory vs. catalytic genes |

| High Efficiency (>110%) | Risk of non-specific amplification; overestimation | False-positive induction of pathway genes |

| Narrow Dynamic Range | Loss of linearity at expression extremes | Inaccurate fold-change for highly induced/repressed genes |

| High Ct Variability | Increased error in ΔΔCt calculation | Reduced power to detect significant pathway modulation |

Experimental Protocols

Protocol 1: Determination of Amplification Efficiency and Dynamic Range

Objective: To validate the performance of a primer set for a biosynthetic pathway gene.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Template Preparation: Generate a 6-log serial dilution (e.g., 1:10 dilutions) of a cDNA sample known to express the target gene. Use at least 5 data points.

- qPCR Setup: Prepare a master mix containing SYBR Green dye, polymerase, dNTPs, buffer, and primers. Aliquot into a 96-well plate.

- Loading: Add each cDNA dilution to triplicate wells. Include No-Template Controls (NTCs) for each primer pair.

- Run Conditions:

- Stage 1 (Enzyme Activation): 95°C for 2 min.

- Stage 2 (Cycling, 40x): Denature at 95°C for 5 sec, Anneal/Extend at 60°C for 30 sec (acquire SYBR Green signal).

- Stage 3 (Melting Curve): 65°C to 95°C, increment 0.5°C/5 sec.

- Data Analysis:

- Ct Acquisition: Set fluorescence threshold consistently in the exponential phase.

- Standard Curve: Plot mean Ct (y-axis) vs. log10(concentration or dilution factor) (x-axis).

- Calculate Efficiency: Determine slope via linear regression. Apply formula ( E = (10^{-1/slope} - 1) * 100% ).

- Assess Dynamic Range: Confirm linearity (R² ≥ 0.990) across all dilutions. The lowest concentration with a reproducible Ct (CV < 5%) defines the lower limit.

Protocol 2: Validating Assays for Relative Quantification (ΔΔCt)

Objective: To establish a robust workflow for comparing expression of BGC genes across experimental conditions.

Procedure:

- RNA Quality Control: Verify RNA Integrity Number (RIN) > 8.0 (Agilent Bioanalyzer).

- Reverse Transcription: Use a fixed amount of RNA (e.g., 1 µg) with random hexamers and a robust reverse transcriptase. Include a no-RT control for each sample to detect gDNA contamination.

- Reference Gene Selection: Validate at least two stable reference genes (e.g., rpoB, gyrB) across all experimental conditions using algorithms like geNorm or NormFinder. Their amplification efficiencies must match target gene efficiencies (difference < 5%).

- qPCR Run: Perform reactions for target and reference genes on all cDNA samples in technical triplicates alongside the efficiency/dynamic range standard curve (Protocol 1).

- Data Processing:

- Calculate mean Ct for replicates.

- Apply the ΔΔCt method: ( \DeltaΔCt = (Ct{Target} - Ct{Ref}){Condition A} - (Ct{Target} - Ct{Ref}){Condition B} )

- Calculate fold-change: ( 2^{-\DeltaΔCt} ).

- Critical Step: Incorporate correction for amplification efficiency if E is not 100%: ( Fold Change = (E{Target})^{-\Delta Ct Target} / (E{Ref})^{-\Delta Ct Ref} ).

Visualizations

Title: RT-qPCR Assay Validation Workflow for Efficiency & Dynamic Range

Title: Data Flow for Relative Quantification (ΔΔCt) with Efficiency Correction

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for RT-qPCR in BGC Analysis

| Item | Function & Rationale | Example Vendor/Catalog (Typical) |

|---|---|---|

| High-Fidelity Reverse Transcriptase | Converts RNA to cDNA with high efficiency and low bias; critical for representative cDNA pools from complex BGC transcripts. | Thermo Fisher Scientific SuperScript IV |

| SYBR Green Master Mix | Provides all components for robust qPCR, including hot-start polymerase, optimized buffer, and fluorescent dye for real-time detection. | Bio-Rad SSoAdvanced SYBR Green |

| gDNA Removal Additive | Ensures RNA samples are free of genomic DNA contamination, preventing false-positive amplification, crucial for intron-spanning validation. | Promega RQ1 RNase-Free DNase |

| Validated Reference Gene Assays | Pre-optimized primer/probe sets for stable reference genes (e.g., rpoB); essential for reliable ΔΔCt normalization in microbial systems. | Integrated DNA Technologies PrimeTime qPCR Assays |

| Nuclease-Free Water | Used for all dilutions to prevent RNase/DNase degradation of sensitive templates and primers. | Ambion UltraPure DNase/RNase-Free Water |

| Digital Pipettes & Calibrated Tips | Ensures accurate and precise liquid handling for serial dilutions and reaction setup, directly impacting reproducibility of Ct values. | Eppendorf Research Plus series |

This application note, framed within a thesis on RT-qPCR for biosynthetic gene expression analysis, details protocols for identifying and quantifying key biosynthetic cluster genes. The analysis of Polyketide Synthases (PKS), Non-Ribosomal Peptide Synthetases (NRPS), and Terpene synthases/Cyclases, alongside housekeeping genes, is critical for natural product discovery and metabolic engineering in drug development.

Research Reagent Solutions Toolkit

| Item | Function |

|---|---|

| High-Fidelity DNA Polymerase | For accurate amplification of target gene fragments from genomic DNA/cDNA. |

| RNA Isolation Kit (e.g., column-based) | For high-integrity total RNA extraction from microbial/cell cultures, removing genomic DNA. |

| cDNA Synthesis Reverse Transcriptase | Converts mRNA to stable cDNA for subsequent qPCR analysis. |

| SYBR Green or TaqMan qPCR Master Mix | Contains enzymes, dNTPs, buffer, and fluorescent probe for real-time PCR quantification. |

| Validated Primer/Probe Sets | Specific for PKS (KS domain), NRPS (A domain), Terpene (TC domain), and housekeeping genes. |

| Microplate Sealing Film | Prevents evaporation and contamination during qPCR thermocycling. |

Key Biosynthetic Gene Targets & Housekeeping Controls

Target genes are selected from conserved core domains within biosynthetic gene clusters (BGCs). Housekeeping genes, constitutively expressed, normalize expression data.

Table 1: Target Gene Domains and Housekeeping Genes

| Gene Category | Target Domain/Gene | Primary Function | Typical Amplicon Size (bp) |

|---|---|---|---|

| Type I PKS | Ketosynthase (KS) | Chain elongation by decarboxylative Claisen condensation | 150-200 |

| NRPS | Adenylation (A) | Substrate amino acid recognition and activation | 180-220 |

| Terpene | Terpene Cyclase/Synthase (TC) | Cyclization of linear isoprenoid precursors | 130-180 |

| Housekeeping | rpoB (RNA polymerase β-subunit) | DNA-dependent RNA transcription | 100-150 |

| Housekeeping | gyrB (DNA gyrase subunit B) | DNA supercoiling | 100-150 |

| Housekeeping | 16S rRNA | Ribosomal RNA component | 80-120 |

Table 2: Example Quantitative Expression Data (ΔΔCq)

| Sample Condition | PKS (KS) ΔΔCq | NRPS (A) ΔΔCq | Terpene (TC) ΔΔCq | rpoB Cq (Mean ± SD) |

|---|---|---|---|---|

| Control (Uninduced) | 0.0 (Ref) | 0.0 (Ref) | 0.0 (Ref) | 20.5 ± 0.3 |

| Induced (24h) | -4.2 | -3.1 | -5.5 | 20.7 ± 0.4 |

| Nutrient-Limited | 1.8 | 0.5 | -1.2 | 20.9 ± 0.2 |

Protocols

Protocol 1: Identification of Target Genes from Genomic DNA

Objective: Amplify diagnostic fragments of key biosynthetic genes for cluster identification. Steps:

- DNA Extraction: Purify high-molecular-weight genomic DNA from your strain using a standard phenol-chloroform method.

- Degenerate PCR:

- Prepare 50 μL reactions: 1X HF buffer, 0.2 mM dNTPs, 0.5 μM degenerate primers (e.g., KS forward/reverse), 1 ng/μL gDNA, 1 U polymerase.

- Thermocycling: 98°C 30s; 35 cycles of [98°C 10s, 48-52°C (gradient) 30s, 72°C 45s]; 72°C 5 min.

- Gel Analysis: Run products on 1% agarose gel. Excise, purify, and sequence bands of expected size.

- Bioinformatic Analysis: BLAST translated sequences against conserved domain databases (e.g., NCBI CDD, antiSMASH) to confirm identity.

Protocol 2: RT-qPCR for Gene Expression Quantification

Objective: Quantify relative expression of biosynthetic target genes versus housekeeping controls. Steps:

- RNA Extraction & DNase Treatment: Isolate total RNA using an RNA-specific kit. Treat with RNase-free DNase I to remove genomic DNA contamination. Verify integrity via agarose gel (sharp rRNA bands).

- cDNA Synthesis: Use 500 ng total RNA in a 20 μL reaction with reverse transcriptase and random hexamer primers. Include a no-RT control (-RT) for each sample to check for DNA contamination.

- qPCR Setup:

- Prepare reactions in triplicate: 1X Master Mix, 0.3 μM each primer, 2 μL cDNA template (diluted 1:10), nuclease-free water to 20 μL.

- Use a two-step program: 95°C 3 min; 40 cycles of [95°C 15s, 60°C 30s (acquire fluorescence)].

- Include a no-template control (NTC).

- Data Analysis:

- Calculate mean Cq for each gene.

- Use the 2^(-ΔΔCq) method: ΔCq = Cq(target) - Cq(housekeeping mean). ΔΔCq = ΔCq(treated) - ΔCq(control calibrator).

- Validate housekeeping gene stability across conditions (Cq SD < 0.5).

Diagrams

Title: Gene Identification and Expression Analysis Workflow

Title: Core Biosynthetic Pathways and Clusters

Step-by-Step RT-qPCR Protocol for Biosynthetic Gene Expression Profiling

This protocol details the initial, critical phase for a thesis focusing on RT-qPCR analysis of biosynthetic gene clusters (BGCs) in microbial or plant systems. Reproducible, high-quality RNA extraction is paramount, as the expression levels of BGCs (e.g., for polyketide synthases or non-ribosomal peptide synthetases) directly influence metabolite yield and are a key variable in drug discovery pipelines.

Experimental Design Considerations

Table 1: Key Design Variables for Culture & Harvest

| Variable | Microbial Cultures | Plant Cell/Tissue Cultures | Rationale for RT-qPCR Analysis |

|---|---|---|---|

| Growth Medium | Defined (e.g., M9, R2A) vs. Complex (e.g., LB, TSB) | Murashige & Skoog (MS) medium, hormone supplementation | Medium composition dramatically influences BGC expression profiles. |

| Induction/Stress | Additive induction (e.g., with acyl homoserine lactones), co-culture, nutrient limitation | Elicitor addition (e.g., methyl jasmonate, fungal extracts) | Standard method to activate silent or lowly expressed BGCs for detection. |

| Growth Phase | Mid-log vs. Stationary phase sampling. | Exponential vs. Stationary growth phase. | BGC expression is often growth-phase-dependent. |

| Replication | Minimum n=3 biological replicates (independent cultures). | Minimum n=3 biological replicates (independent flasks/plates). | Essential for statistical significance in subsequent qPCR data analysis. |

| Control Samples | Wild-type vs. mutant, vehicle-only treated cultures. | Untreated vs. elicited, different tissue types. | Required for calculating fold-change in gene expression (ΔΔCq method). |

Detailed Protocol: Sample Preparation for RNA Extraction

A. Harvesting Microbial Cultures

Materials: Culture flasks, centrifuge, sterile pipettes, cryogenic vials, liquid nitrogen, RNase-free consumables.

- Induction: Treat cultures per experimental design. Record exact OD600 at harvest (e.g., OD600 = 0.6 for mid-log).

- Rapid Quenching: Immediately withdraw a volume containing ~5x10^8 cells (e.g., 1-10 mL depending on OD) into a tube containing a 1:1 ratio of frozen quenching buffer (60 mM NaH₂PO₄, 40 mM K₂HPO₄, pH 7.0 at -20°C).

- Pelletting: Centrifuge at 4°C, 5,000 x g for 5 min. Discard supernatant completely.

- Stabilization: Flash-freeze pellet in liquid nitrogen. Store at -80°C until RNA extraction, or proceed directly to lysis.

B. Harvesting Plant Culture Cells/Tissues

Materials: Vacuum filtration apparatus, sterile forceps, mortar & pestle (pre-chilled), liquid nitrogen.

- Collection: Pour suspension cultures rapidly onto a nylon membrane under gentle vacuum. For callus, use sterile forceps.

- Rinse: Briefly wash with ice-cold, RNase-free phosphate-buffered saline.

- Flash-Freeze: Immediately transfer tissue (≤100 mg) to a mortar pre-chilled with liquid nitrogen. Grind to a fine powder.

- Transfer: Using a pre-chilled spatula, transfer powder to a tube containing lysis/binding buffer from an RNA kit. Keep frozen until homogenization.

Critical: RNA Extraction & Quality Control

- Method: Use a commercial kit validated for your sample type (e.g., with bead-beating for microbes, polysaccharide removal for plants). Include an on-column DNase I digest step.

- QC Parameters: Use a spectrophotometer (NanoDrop) and bioanalyzer (Agilent). Acceptable RNA for RT-qPCR:

- Concentration: >50 ng/µL.

- Purity: A260/A280 ≈ 2.0, A260/A230 > 2.0.

- Integrity: RIN (RNA Integrity Number) ≥ 8.0 or clear 23S/16S (microbial) or 28S/18S (plant) ribosomal bands.

Table 2: Acceptable RNA Quality Metrics for RT-qPCR

| Metric | Ideal Value | Acceptable Range | Measurement Tool |

|---|---|---|---|

| A260/A280 | 2.10 | 1.9 - 2.1 | Spectrophotometer |

| A260/A230 | 2.20 | >1.8 | Spectrophotometer |

| RIN | 10 | ≥ 8.0 | Bioanalyzer / TapeStation |

| Total Yield | ≥ 1 µg per sample | >500 ng | Spectrophotometer / Fluorometer |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Phase 1

| Item | Function & Importance |

|---|---|

| RNase Zap / RNase AWAY | Decontaminates surfaces to prevent RNase degradation of samples. |

| Liquid Nitrogen & Dewar | Enables rapid quenching of metabolism and tissue pulverization without RNA degradation. |

| Commercial RNA Extraction Kit | Provides optimized buffers, silica membranes, and DNase for reproducible, high-quality RNA. |

| RNase-free Tubes & Filter Tips | Prevents introduction of nucleases during liquid handling. |

| β-Mercaptoethanol or RNase Inhibitors | Added to lysis buffer to inhibit endogenous RNases, especially critical in plant tissues. |

| RNA Stabilization Reagent (e.g., RNA_later) | Option for field sampling or when immediate freezing is impossible; penetrates tissue to stabilize RNA. |

| Spectrophotometer / Fluorometer | For accurate quantification and preliminary purity assessment of nucleic acids. |

| Bioanalyzer / TapeStation | Assesses RNA integrity, which is critical for reliable reverse transcription efficiency. |

Visualized Workflows & Pathways

Title: Phase 1: Sample Prep Workflow for RT-qPCR

Title: Signaling Pathways for BGC Induction

Within a thesis on RT-qPCR for biosynthetic gene expression analysis, the reliability of downstream data is fundamentally limited by the quality of the input RNA. Complex biological matrices—such as tissues rich in secondary metabolites (e.g., plant biosynthetic tissues), fibrous samples, or samples with high RNase activity—present formidable challenges for RNA isolation. This application note provides updated protocols and considerations for obtaining high-integrity RNA from such matrices, ensuring optimal performance in sensitive RT-qPCR assays used to quantify expression of genes in pathways like alkaloid or terpenoid biosynthesis.

Challenges in RNA Isolation from Complex Matrices

Complex matrices introduce specific inhibitors and integrity risks:

- Polysaccharides and Polyphenols: Common in plant tissues, they co-precipitate with RNA, inhibiting downstream enzymatic reactions.

- High RNase Activity: Present in pancreas, spleen, or microbial co-cultures, leading to rapid RNA degradation.

- High Lipid Content: Adipose tissue or seeds require effective dissociation.

- Fibrous Structures: Muscle or plant cell walls necessitate vigorous homogenization.

- Low Abundance Targets: Analyzing transcripts from rare cell types within a tissue requires high yields.

Key Research Reagent Solutions

The following table lists essential reagents and materials for high-quality RNA isolation from challenging samples.

Table 1: Research Reagent Solutions for Complex RNA Isolation

| Item | Function & Rationale |

|---|---|

| Liquid Nitrogen | Enables instant freezing, halting RNase activity, and brittle fracture of tough tissues for effective grinding. |

| Guaridine Isothiocyanate (GITC)-Based Lysis Buffer | A potent chaotropic agent that denatures proteins and RNases immediately upon cell lysis. |

| β-Mercaptoethanol or DTT | Reducing agent added to lysis buffer to inhibit oxidization of polyphenols, preventing browning and co-precipitation. |

| RNA-specific Solid-Phase Silica Columns | Selective binding of RNA in high-salt conditions, allowing removal of contaminants through efficient washing steps. |

| DNase I (RNase-free) | On-column or in-solution digestion of genomic DNA to prevent PCR-amplifiable DNA contamination in RT-qPCR. |

| Magnetic Beads (poly-dT functionalized) | For mRNA isolation directly from lysates; useful for removing inhibitory compounds and enriching for coding RNA. |

| RNase Inhibitors (Protein-based) | Added to eluted RNA or reaction mixes for long-term storage or sensitive applications to protect against minor RNase contamination. |

| Inhibitor Removal Additives (e.g., BSA, PVP) | Added to lysis buffers to bind and sequester polysaccharides and polyphenols, preventing co-isolation. |

| PCR Inhibitor Removal Columns | Post-isolation clean-up step for samples persistently inhibitory to reverse transcriptase or Taq polymerase. |

| Integrity Assessment Reagents (e.g., Lab-on-a-chip systems) | For precise RIN determination, superior to agarose gels for quantitative integrity measurement. |

Optimized Protocol for Fibrous/Polyphenol-Rich Tissue (e.g., Plant Biosynthetic Tissue)

This detailed protocol is optimized for tissues like Catharanthus roseus leaves (terpenoid indole alkaloid pathway) or Taxus bark (taxol pathway).

Materials: Liquid N₂, mortar & pestle, GITC-based lysis buffer (commercial or prepared), β-mercaptoethanol (2%), polyvinylpyrrolidone (PVP-40), isopropanol, 75% ethanol (DEPC-treated), silica-membrane spin columns, DNase I kit, RNase-free water.

Procedure:

- Harvest & Snap-Freeze: Excise tissue rapidly, immediately submerge in liquid N₂. Store at -80°C.

- Homogenization: Under liquid N₂, grind tissue to a fine powder using a pre-chilled mortar and pestle. Do not let the tissue thaw.

- Lysis: Transfer ~100 mg powder to a tube containing 1 mL pre-warmed (65°C) lysis buffer with 2% β-mercaptoethanol and 2% PVP-40. Vortex vigorously immediately.

- Separation: Centrifuge at 12,000 x g, 10 min, 4°C, to pellet debris/polysaccharides.

- Binding: Transfer supernatant to a new tube. Add 0.5 vol isopropanol, mix. Load onto silica column.

- Wash: Wash column twice with ethanol-based wash buffer as per manufacturer’s instructions.

- DNase Treatment: Apply DNase I solution directly to column membrane. Incubate at RT for 15 min.

- Final Wash & Elution: Perform two additional column washes. Elute RNA in 30-50 µL RNase-free water (pre-heated to 65°C).

- Assessment: Proceed to quantification and integrity analysis.

Quantitative Assessment of RNA Quality & Yield

Table 2: Assessment Metrics for Isolated RNA

| Metric | Target Value | Method | Significance for RT-qPCR |

|---|---|---|---|

| Yield | Sample & method dependent | Spectrophotometry (A260) | Ensures sufficient material for all required assays and replicates. |

| Purity (A260/A280) | 1.9 - 2.1 | Spectrophotometry | Low ratio indicates protein/phenol contamination (inhibits RT). |

| Purity (A260/A230) | 2.0 - 2.4 | Spectrophotometry | Low ratio indicates salt, guanidine, or carbohydrate carryover (inhibits PCR). |

| RNA Integrity Number (RIN) | ≥ 7.0 (≥ 8.5 ideal) | Microfluidics (e.g., Bioanalyzer) | Predicts amplifiability; degraded RNA leads to 3' bias and inaccurate quantification. |

| DV200 (Fragment >200nt) | ≥ 70% | Microfluidics | Critical for FFPE or degraded samples; indicates usable RNA fraction. |

| RT-qPCR Amplification Efficiency | 90-110% (R² > 0.99) | Standard Curve (dilution series) | Direct functional test of RNA quality; reduced efficiency indicates inhibitors. |

Experimental Protocol: RNA Integrity Analysis via Microfluidics

Cite: Use of Agilent Bioanalyzer 2100 or TapeStation systems. Protocol:

- Prepare RNA samples to a concentration of ~25 ng/µL.

- Denature the RNA ladder and samples at 70°C for 2 minutes, then place on ice.

- Prepare the gel-dye mix and load into the appropriate chip.

- Pipette 1 µL of ladder and 1 µL of each sample into designated wells.

- Vortex the chip and run in the instrument.

- Analyze the electropherograms. The software calculates the RIN based on the entire trace, with emphasis on the 18S and 28S ribosomal RNA peaks for eukaryotic samples.

Workflow: From Tissue to RT-qPCR-Ready RNA

Impact of RNA Integrity on RT-qPCR Data Interpretation

Degraded RNA skews gene expression data due to differential susceptibility of transcripts. This is critical in biosynthetic pathways where rates may be controlled by early (often stable) vs. late (often less stable) transcript abundance.

Successful RT-qPCR analysis of biosynthetic gene expression demands rigorous upfront RNA isolation tailored to the sample matrix. By implementing protocols that actively combat matrix-specific inhibitors and by mandating rigorous QC using both spectrophotometric and integrity-number metrics, researchers can ensure that their gene expression data accurately reflects biology, not isolation artifacts. This foundational step is non-negotiable for producing thesis-worthy, publication-quality data in metabolic engineering and drug discovery research.

In a thesis investigating biosynthetic gene expression via RT-qPCR, the accuracy of quantification is paramount. A primary confounding factor is genomic DNA (gDNA) contamination in RNA samples, which can lead to false-positive signals and inflated expression values. This application note details the critical checkpoints for DNase treatment and subsequent RNA purity assessment, establishing a rigorous pre-amplification workflow essential for reliable gene expression data in metabolic engineering and drug development research.

The Purity Problem: gDNA Contamination Impact

Contaminating gDNA can co-amplify with cDNA during qPCR, especially when primer sets span small introns or when analyzing intron-less genes. This compromises data integrity, affecting conclusions on gene expression changes in biosynthetic pathways.

Table 1: Impact of gDNA Contamination on RT-qPCR Ct Values

| Sample Condition | Average Ct (Target Gene) | ΔCt vs. -RT Control | Implied Fold-Error |

|---|---|---|---|

| Pure RNA (Effective DNase Treat.) | 23.5 | 15.2 | 1x (Baseline) |

| RNA with Residual gDNA (No DNase) | 21.7 | 13.4 | ~3.5x Overestimate |

| DNase-Treated, No Heat Inactivation | 24.8 | 16.5 | ~2.3x Underestimate |

| -RT Control (No Reverse Transcriptase) | 38.7 | N/A | N/A |

Table 2: Spectrophotometric & Fluorometric Purity Benchmarks

| Purity Metric | Acceptable Range | Ideal Value | Method/Instrument |

|---|---|---|---|

| A260/A280 Ratio | 1.8 - 2.1 | 2.0 | Spectrophotometer |

| A260/A230 Ratio | >2.0 | 2.2 - 2.5 | Spectrophotometer |

| RNA Integrity Number (RIN) | ≥7.0 (for RT-qPCR) | 8.5 - 10.0 | Bioanalyzer/TapeStation |

| gDNA Contamination | Ct >5 cycles above sample Ct | No detectable signal | qPCR with gDNA-specific assay |

Experimental Protocols

Protocol 1: Rigorous DNase I Treatment (On-Column & In-Solution)

A. On-Column DNase I Treatment (During RNA Purification)

- Materials: Silica-membrane spin column, RNA wash buffers, DNase I (RNase-free), DNase reaction buffer (10x).

- Procedure:

- After lysate binding and initial washes, prepare an on-column DNase I mix: 10 µL 10x DNase buffer, 5 µL DNase I (5 U/µL), 85 µL RNase-free water.

- Apply the 100 µL mix directly to the center of the column membrane. Incubate at room temperature for 15 minutes.

- Perform the standard wash steps as per the kit protocol. Elute RNA in RNase-free water.

B. In-Solution DNase I Treatment (Post-Purification)

- Materials: Purified RNA, DNase I (RNase-free), 10x Reaction Buffer, EDTA, Thermocycler or heat block.

- Procedure:

- In a nuclease-free tube, combine: RNA sample (up to 8 µg), 5 µL 10x DNase buffer, 2 µL DNase I (5 U/µL). Adjust to 50 µL with RNase-free water.

- Incubate at 37°C for 30 minutes.

- Critical Checkpoint: Inactivate DNase I by adding 5 µL of 50 mM EDTA (final 5 mM) and heating at 65°C for 10 minutes. Alternatively, use a kit with an inactivation reagent.

- Purify the treated RNA using a standard RNA clean-up protocol to remove EDTA and enzyme.

Protocol 2: Post-DNase Purity Assessment Workflow

- Spectrophotometric Analysis: Use 1-2 µL to determine A260/A280 and A260/A230 ratios.

- Fluorometric Quantification: Use RNA-specific dye (e.g., RiboGreen) for accurate concentration, unaffected by contaminants.

- Integrity Analysis: Run 100-500 ng on a Bioanalyzer RNA Nano chip to obtain RIN.

- gDNA Contamination qPCR Assay (MANDATORY):

- Primer Design: Design primers that span a large genomic intron or target a non-transcribed region.

- Reaction Setup: Perform a standard qPCR reaction without reverse transcriptase (-RT control) on 50-100 ng equivalent of your DNase-treated RNA.

- Interpretation: A Ct value in the -RT control that is >5 cycles later than the +RT sample Ct indicates acceptable gDNA removal. A difference of <3 cycles signifies significant contamination.

Visualization: Experimental Workflow & Logical Decision Tree

Title: RNA Purity Checkpoint Workflow

Title: gDNA Contamination Causes False qPCR Signal

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for DNase Treatment & RNA Purity Analysis

| Item & Example | Function & Critical Note |

|---|---|

| RNase-free DNase I (Recombinant) | Digests single/double-stranded DNA contaminants. Must be RNase-free to prevent sample degradation. |

| 10x DNase I Reaction Buffer (with Mg²⁺/Ca²⁺) | Provides optimal ionic conditions and cofactors for DNase I enzymatic activity. |

| EDTA (50 mM, RNase-free) | Chelates Mg²⁺/Ca²⁺, irreversibly inactivating DNase I post-treatment to halt reaction. |

| RNA Clean-up Kit (Silica-membrane) | Removes enzymes, salts, and EDTA after in-solution DNase treatment; concentrates RNA. |

| Fluorometric RNA Assay Dye (e.g., RiboGreen) | Provides RNA-specific quantification, unaffected by common contaminants like salts or gDNA. |

| Automated Electrophoresis System (e.g., Bioanalyzer) | Assesses RNA integrity (RIN) and detects gDNA contamination via electrophoretic profile. |

| gDNA-specific qPCR Primers | Amplify a genomic region absent from mature mRNA to test for residual gDNA contamination. |

| No-Reverse Transcriptase (-RT) Control Mix | Essential qPCR control containing all reagents except reverse transcriptase. |

Within the context of RT-qPCR for biosynthetic gene expression analysis, the choice of reverse transcription (RT) priming method is a critical initial step that dictates cDNA yield, representation, and downstream quantification accuracy. The three predominant strategies—random hexamers, oligo-dT, and gene-specific primers (GSPs)—each have distinct advantages and limitations. This application note provides a comparative analysis and detailed protocols to guide researchers and drug development professionals in selecting the optimal priming approach for their experimental goals, particularly when analyzing genes involved in complex biosynthetic pathways.

Comparative Analysis of Priming Methods

Table 1: Quantitative and Qualitative Comparison of RT Priming Methods

| Parameter | Random Hexamers | Oligo-dT Primers | Gene-Specific Primers (GSPs) |

|---|---|---|---|

| Priming Site | Throughout entire RNA transcript, including non-poly(A) regions. | Poly(A) tail of eukaryotic mRNA. | Specific, pre-defined sequence within target mRNA. |

| cDNA Yield | High (primes all RNA). | High for poly(A)+ mRNA. | Low to moderate (target-specific). |

| Coverage/Bias | Broad, uniform coverage of all RNA species; can over-represent rRNA. | 3'-biased; only primes poly(A)+ mRNA. | Extremely specific; only generates cDNA of the target. |

| Ideal RNA Quality | Tolerant of partially degraded RNA. | Requires intact poly(A) tail; degraded RNA leads to 3' bias. | Requires intact target sequence region. |

| Primary Application | Whole transcriptome analysis, degraded samples, non-poly(A) RNA (e.g., bacterial). | Standard mRNA analysis, long transcripts, alternative polyadenylation studies. | High-sensitivity, single-target RT-qPCR; multiplex RT. |

| RT-qPCR Efficiency | Good, but may require optimization of primer binding sites. | Good for assays near 3' end; poor for 5' distal assays if RNA is degraded. | Excellent, as cDNA is synthesized specifically for the subsequent qPCR assay. |

| Multiplexing Potential | Low (generates complex cDNA background). | Moderate (generates only mRNA-derived cDNA). | High (can use multiple GSPs in one reaction). |

Table 2: Recommended Use Cases in Biosynthetic Gene Expression Analysis

| Research Scenario | Recommended Priming Method | Rationale |

|---|---|---|

| Screening expression of multiple genes in a biosynthetic pathway from high-quality RNA. | Oligo-dT | Provides a comprehensive cDNA library of all mRNAs from a single reaction, ideal for analyzing multiple pathway genes. |

| Quantifying a specific, low-abundance transcript (e.g., a rate-limiting enzyme). | Gene-Specific Primer | Maximizes sensitivity and cDNA yield for that specific target, reducing background. |

| Analyzing samples with potential RNA degradation (e.g., field samples, FFPE tissue). | Random Hexamers | Primes from internal sites, generating cDNA from fragments, providing more reliable data than oligo-dT. |

| Studying non-coding RNAs or prokaryotic genes (lacking poly-A tails). | Random Hexamers | Does not require a poly-A tail for priming. |

| Performing one-step RT-qPCR for a defined target. | Gene-Specific Primer | The standard and most efficient approach for one-step protocols. |

Detailed Experimental Protocols

Protocol 1: Reverse Transcription Using Random Hexamers

Objective: To generate cDNA representative of all RNA species in a sample. Materials: See "The Scientist's Toolkit" section.

- RNA Template Prep: Dilute 10 pg – 1 µg of total RNA in nuclease-free water to a final volume of 8 µL in a sterile PCR tube.

- Primer Annealing: Add 1 µL of Random Hexamer Primer (50 µM stock) and 1 µL of dNTP Mix (10 mM each). Mix gently and spin down.

- Denaturation & Annealing: Incubate at 65°C for 5 minutes, then immediately place on ice for at least 1 minute.

- Master Mix Preparation: On ice, prepare the following for each reaction: 4 µL of 5X Reverse Transcription Buffer, 1 µL of RNase Inhibitor (20 U/µL), 2 µL of 0.1 M DTT, and 1 µL of Reverse Transcriptase (200 U/µL).

- cDNA Synthesis: Add 8 µL of the master mix to the RNA/primer mix. Mix gently. Incubate in a thermal cycler: 25°C for 5 min (primer extension), 50°C for 45-60 min (reverse transcription), 70°C for 15 min (enzyme inactivation). Hold at 4°C.

- Post-RT Handling: Dilute cDNA 1:5 to 1:10 with nuclease-free water before qPCR. Store at -20°C.

Protocol 2: Reverse Transcription Using Oligo-dT Primers

Objective: To generate cDNA specifically from polyadenylated mRNA. Materials: See "The Scientist's Toolkit" section.

- Steps 1-3 as in Protocol 1, but replace random hexamers with 1 µL of Oligo-dT Primer (50 µM stock).

- Master Mix Preparation: As in Protocol 1.

- cDNA Synthesis: Add master mix and incubate as in Protocol 1.

- Post-RT Handling: As in Protocol 1.

Protocol 3: Two-Step RT-qPCR Using Gene-Specific Primers

Objective: To generate cDNA optimized for the subsequent quantification of a specific target. Materials: See "The Scientist's Toolkit" section.

- RNA Template Prep: As in Protocol 1.

- Primer Annealing: Add 1 µL of Gene-Specific Reverse Primer (2 µM stock) and 1 µL of dNTP Mix (10 mM each). Mix and spin.

- Denaturation & Annealing: Incubate at 65°C for 5 min, then immediately place on ice for 1 min. For primers with a lower Tm, incubate at 42-50°C for 2-5 min instead.

- Master Mix Preparation: As in Protocol 1.

- cDNA Synthesis: Add master mix. Incubate: 42-50°C for 45-60 min (gene-specific priming), 70°C for 15 min. Hold at 4°C.

- Post-RT Handling: Use 1-5 µL of undiluted or diluted cDNA directly in the subsequent qPCR reaction.

Visualizing the Decision Workflow and Process

RT Priming Method Decision Workflow

Three RT Priming Methods Compared

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Reverse Transcription

| Item | Function & Specification | Example/Brand Considerations |

|---|---|---|

| Reverse Transcriptase | Enzyme that synthesizes cDNA from an RNA template. High processivity and thermal stability are advantageous. | M-MLV, SuperScript IV, PrimeScript. RNase H- variants reduce RNA degradation. |

| RNase Inhibitor | Protects RNA templates from degradation by RNases during the reaction. | Recombinant RNase Inhibitor (e.g., RNasin). Essential for sensitive/long reactions. |

| dNTP Mix | Deoxynucleotide triphosphates (dATP, dCTP, dGTP, dTTP) provide building blocks for cDNA synthesis. | 10 mM each dNTP, pH 8.0. Use high-purity, PCR-grade. |

| Primers | Initiates cDNA synthesis. Choice defines method (random hexamers, oligo-dT, GSP). | Nuclease-free, HPLC-purified. Random hexamers: 50 µM stock. Oligo-dT (12-18mer): 50 µM. GSP: 2 µM. |

| 5X RT Buffer | Provides optimal pH, ionic strength, and co-factors (e.g., Mg2+) for the reverse transcriptase. | Typically supplied with enzyme. May include DTT. |

| Nuclease-Free Water | Solvent for dilutions. Must be RNase/DNase-free to prevent sample degradation. | Certified nuclease-free, DEPC-treated or equivalent. |

| Thermal Cycler | Provides precise temperature control for denaturation, annealing, and extension steps. | Standard PCR thermal cycler. |

| RNA Quantification Tool | Accurately measures RNA concentration and assesses purity (A260/A280). | UV-Vis spectrophotometer (NanoDrop) or fluorometer (Qubit). |

Within the framework of a broader thesis on RT-qPCR for biosynthetic gene expression analysis, the selection of detection chemistry is paramount. This choice directly impacts the specificity, accuracy, and reliability of quantifying low-abundance transcripts from complex pathways, such as those involved in polyketide or terpenoid biosynthesis. The core decision often hinges on the need for specificity: SYBR Green I dye offers a cost-effective, flexible solution, while hydrolysis (TaqMan) probes provide superior specificity for discriminating closely related gene family members or splice variants, a common challenge in metabolic engineering research.

Chemistry Comparison: Mechanism and Application

Key Principles

- SYBR Green I: A fluorescent dye that intercalates into any double-stranded DNA (dsDNA) product, including non-specific amplicons and primer-dimers.

- Probe-Based (TaqMan): Utilizes a sequence-specific oligonucleotide probe labeled with a reporter fluorophore and a quencher. Fluorescence increases only upon probe cleavage during amplification, ensuring signal is derived solely from the target sequence.

Quantitative Comparison Table

Table 1: Direct Comparison of SYBR Green and Probe-Based qPCR Chemistries

| Parameter | SYBR Green I | Probe-Based (TaqMan) | Implication for Biosynthetic Gene Analysis |

|---|---|---|---|

| Specificity | Low-Medium (post-run melt curve required) | Very High (probe hybridization) | Critical for homologous gene clusters. Probes preferred for high specificity. |

| Multiplexing | No | Yes (with different colored probes) | Enables simultaneous quantification of a target gene and a housekeeper or multiple pathway genes. |

| Cost per Reaction | Low (~$0.50 - $1.50) | High (~$2.50 - $5.00) | SYBR Green is advantageous for high-throughput screening of many candidates. |

| Assay Design & Validation | Simple (primer design only) | Complex (primer + probe design, optimization) | SYBR Green allows rapid assay development for novel pathways. |

| Background Signal | Higher (binds any dsDNA) | Lower (quenched probe) | Probes offer better signal-to-noise for low-expression transcripts. |

| Protocol Length | Standard | Standard | Comparable hands-on time. |

| Optimal Use Case | Gene expression screening, validation of single targets, melt curve analysis. | High-fidelity quantitation, multiplexing, detecting SNPs/splice variants. | Probe-based is the gold standard for publicable, definitive quantitation of key pathway genes. |

Detailed Experimental Protocols

Protocol 3.1: SYBR Green I qPCR Setup with Melt Curve Analysis

Objective: To quantify expression of a biosynthetic gene (e.g., a polyketide synthase) with verification of amplicon specificity.

I. Reagent Setup (25 µL Reaction)

- Prepare reactions on ice in a optical-grade 96-well plate.

- 2X SYBR Green Master Mix: 12.5 µL

- Forward Primer (10 µM): 1.0 µL

- Reverse Primer (10 µM): 1.0 µL

- cDNA Template (diluted 1:10): 2.0 µL

- Nuclease-free H(_2)O: 8.5 µL

- Total Volume: 25.0 µL

- Run all samples and controls in technical triplicate.

II. Cycling Conditions (Standard Instrument)

- Uracil-DNA Glycosylase (UDG) Incubation (Optional): 50°C for 2 min.

- Initial Denaturation: 95°C for 2 min.

- Amplification (40 cycles):

- Denature: 95°C for 15 sec.

- Anneal/Extend: 60°C for 1 min (acquire fluorescence).

- Melt Curve Analysis:

- 95°C for 15 sec.

- 60°C for 1 min.

- Ramp to 95°C at 0.3°C/sec, continuously acquiring fluorescence.

III. Data Analysis

- Use instrument software to determine Cq values using a baseline and threshold set within the exponential phase.

- Analyze melt curves: A single sharp peak indicates specific amplification. Multiple peaks suggest primer-dimer or non-specific products.

Protocol 3.2: Probe-Based (TaqMan) qPCR Setup

Objective: To achieve high-specificity, multiplexed quantification of a target biosynthetic gene and an endogenous control (e.g., 18S rRNA).

I. Reagent Setup (20 µL Reaction)

- 2X TaqMan Universal PCR Master Mix: 10.0 µL

- Target Gene Assay (Primers + Probe, 20X): 1.0 µL

- Endogenous Control Assay (20X, different dye): 1.0 µL

- cDNA Template: 2.0 µL

- Nuclease-free H(_2)O: 6.0 µL

- Total Volume: 20.0 µL

II. Cycling Conditions

- Enzyme Activation: 95°C for 20 sec.

- Amplification (40 cycles):

- Denature: 95°C for 1 sec.

- Anneal/Extend: 60°C for 20 sec (acquire fluorescence for all channels).

III. Data Analysis

- Software automatically generates Cq values for each target in each well.

- Use the ΔΔCq method for relative quantification, normalizing the target gene Cq to the endogenous control and a calibrator sample.

Visualized Workflows and Pathways

Diagram Title: qPCR Chemistry Selection Decision Tree

Diagram Title: Fluorescence Generation in SYBR vs TaqMan qPCR

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for RT-qPCR Gene Expression Analysis

| Item | Function & Importance | Example Brand/Type |

|---|---|---|

| SYBR Green Master Mix | Contains SYBR dye, Taq polymerase, dNTPs, and optimized buffer. Essential for dye-based assays. | PowerUp SYBR Green, Brilliant III Ultra-Fast SYBR Green |

| TaqMan Master Mix | Contains UNG, Taq polymerase, dNTPs, and buffer optimized for probe-based assays. | TaqMan Universal Master Mix II, qPCRBIO Probe Mix |

| Primers (for SYBR) | Sequence-specific oligonucleotides for target amplification. High purity (HPLC/ PAGE) is critical. | Custom-designed, HPLC-purified primers |

| Assays (for TaqMan) | Pre-validated, gene-specific primer and probe sets. Includes both primer pair and FAM-labeled probe. | TaqMan Gene Expression Assays |

| Reverse Transcriptase | Enzyme to synthesize cDNA from RNA template for the initial RT step. | SuperScript IV, PrimeScript RT |

| Nuclease-free Water | Solvent for diluting reagents; must be free of RNases and DNases to prevent degradation. | Invitrogen UltraPure, DEPC-treated Water |

| Optical Reaction Plates | Plates and seals compatible with the qPCR instrument's optical system for accurate fluorescence reading. | MicroAmp Optical 96-well plate, optical adhesive film |

| RNA Isolation Kit | For high-quality, intact total RNA extraction from engineered microbial or plant tissues. | RNeasy Mini Kit, TRIzol reagent |

| Digital Pipettes | For accurate and precise low-volume liquid handling (µL range). Crucial for reproducibility. | Eppendorf Research Plus, Thermo Scientific Finnpipette |

Within a thesis on RT-qPCR for biosynthetic gene expression analysis, reaction optimization is critical for generating reliable, reproducible data. This protocol details the steps for validating primer specificity via melting curve analysis and calculating amplification efficiency—fundamental prerequisites for accurate gene expression quantification in metabolic engineering and drug development research.

Primer Validation & Melting Curve Protocol

Objective: To confirm primer specificity and the absence of primer-dimers or non-specific amplification.

Materials:

- qPCR Master Mix (e.g., SYBR Green I chemistry)

- Validated template cDNA (from biosynthetic pathway gene of interest)

- Forward and Reverse Primers (100 µM stock)

- Nuclease-free H(_2)O

- qPCR Instrument (e.g., Applied Biosystems, Bio-Rad, Roche)

Method:

- Prepare a 20 µL qPCR reaction in triplicate:

- 10 µL 2X SYBR Green Master Mix

- 1 µL Forward Primer (10 µM final)

- 1 µL Reverse Primer (10 µM final)

- 2 µL Template cDNA (or standard dilution)

- 6 µL Nuclease-free H(_2)O

- Run the following thermal cycling program:

- Stage 1: Polymerase Activation: 95°C for 2 min.

- Stage 2: Amplification (40 cycles): 95°C for 15 sec (Denaturation), 60°C for 1 min (Annealing/Extension). Collect fluorescence signal.

- Stage 3: Melting Curve: 95°C for 15 sec, 60°C for 1 min, then gradual increase to 95°C (0.3°C/sec increment). Continuously collect fluorescence signal.

- Analysis: Using the instrument software, plot the negative derivative of fluorescence (-d(RFU)/dT) versus temperature. A single, sharp peak indicates specific amplification. Multiple or broad peaks suggest primer-dimer formation or non-specific products.

Amplification Efficiency Calculation Protocol

Objective: To determine the reaction efficiency (E) for each primer pair, essential for accurate relative quantification (ΔΔCq method).

Method:

- Standard Curve Preparation: Serially dilute (e.g., 1:5 or 1:10) a pooled cDNA sample or a plasmid containing the target amplicon to create at least 5 concentration points (e.g., undiluted, 1:10, 1:100, 1:1000, 1:10000). Include a no-template control (NTC).

- qPCR Run: Amplify all standard dilutions in triplicate using the protocol in Section 2 (including melting curve).

- Data Analysis: The instrument software plots the mean Cq (Quantification Cycle) value against the logarithm of the template concentration for each dilution.

- Efficiency Calculation: Determine the slope of the standard curve line.

- Formula: Efficiency ( E = [10^{(-1/slope)}] - 1 )

- Interpretation: An ideal reaction with 100% efficiency has a slope of -3.32. Acceptable efficiency ranges from 90–110% (slope: -3.58 to -3.10).

Data Presentation

Table 1: Standard Curve and Efficiency Data for Biosynthetic Pathway Genes

| Gene Target | Function in Biosynthesis | Standard Curve Slope | Amplification Efficiency (E) | R² of Standard Curve | Melting Peak Temperature (Tm) |

|---|---|---|---|---|---|

| PKS_KS | Ketosynthase Domain | -3.40 | 97.1% | 0.999 | 82.5°C (single peak) |

| NRPS_A | Adenylation Domain | -3.28 | 101.7% | 0.998 | 85.1°C (single peak) |

| CYP450 | Hydroxylation | -3.55 | 91.3% | 0.996 | 81.8°C (single peak) |

| GT_1 | Glycosyltransferase | -3.15 | 107.8% | 0.999 | 84.0°C (single peak) |

| NTC | No Template Control | N/A | N/A | N/A | < 75.0°C (no peak) |

Visualized Workflows

Title: Primer Validation and Efficiency Workflow

Title: Melting Curve Analysis Principle

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in RT-qPCR Optimization |

|---|---|

| SYBR Green I Master Mix | Intercalates into dsDNA, providing fluorescent signal proportional to amplicon mass. Essential for melting curve analysis. |

| Nuclease-Free Water | Solvent for reaction setup, free of RNases and DNases to prevent degradation of primers and templates. |

| Optical qPCR Plates/Seals | Ensure proper thermal conductivity and prevent evaporation and contamination during cycling. |

| cDNA Synthesis Kit (with gDNA removal) | Generates high-quality, genomic DNA-free cDNA from RNA isolates for accurate gene expression analysis. |

| Validated Control cDNA/Primer Set | Provides positive control for reaction setup and inter-run calibration (e.g., housekeeping gene). |

| qPCR Instrument Calibration Kit | Validates optical calibration of the qPCR instrument across different fluorescence channels. |

Introduction Within the broader thesis on RT-qPCR for biosynthetic gene expression analysis, the accuracy of downstream differential expression and pathway modeling hinges entirely on the precision of initial data acquisition and Ct value determination. This application note details the critical steps and best practices for processing raw fluorescence data from RT-qPCR runs to yield robust, reproducible quantitative cycle (Ct) values, the fundamental unit in qPCR analysis.

1. Raw Fluorescence Data Acquisition & Quality Assessment Modern qPCR instruments generate fluorescence readings for each cycle and each well. Initial analysis begins with an assessment of run quality.

Table 1: Key QC Parameters from a Raw Fluorescence Amplification Plot

| Parameter | Optimal Range/Characteristic | Indication of Problem |

|---|---|---|

| Baseline Fluorescence | Stable, low signal before amplification. | High noise suggests reagent or background issues. |

| Amplification Curve Shape | Smooth, sigmoidal with a clear exponential phase. | Irregular shapes may indicate inhibitor carryover or pipetting errors. |

| Plateau Phase | Consistent, high fluorescence signal. | Low plateau suggests low amplicon yield or probe degradation. |

| Replicate Agreement | Tight clustering of technical replicate curves. | High variability indicates poor reaction setup or template quality. |

| NTC (No Template Control) Signal | No amplification within 40 cycles, or late Ct (>40). | Amplification in NTC indicates primer-dimer or contamination. |

2. Baseline Correction and Threshold Setting Accurate Ct determination requires proper baseline subtraction and a consistent fluorescence threshold.

Protocol 2.1: Baseline and Threshold Determination

- Baseline Definition: Manually review or allow the instrument software to automatically set the baseline cycle range. Typically, this is set from cycles 3-15, but it must be before the visible onset of amplification for all samples. Adjust if early amplifying samples are present.

- Automatic Baseline Correction: Apply the correction to subtract the average baseline fluorescence from all cycle data for each well.

- Threshold Setting: Set the threshold line within the linear exponential phase of all amplification plots, sufficiently above the baseline noise. For comparative Ct (ΔΔCt) analysis, the absolute value is arbitrary but must be consistent across all runs within a study.

- Ct Assignment: The Ct for each reaction is the cycle number at which the fluorescence intersects the defined threshold.

3. Ct Determination Methods and Comparative Analysis Different algorithms can impact Ct value precision, especially for low-expression or noisy samples.

Table 2: Common Ct Determination Algorithms

| Algorithm | Methodology | Advantage | Best For |

|---|---|---|---|

| Threshold Cycle | Simple intersection of fluorescence curve with a fixed threshold. | Simple, intuitive, widely used. | Clear, high-quality amplifications. |

| Second Derivative Maximum | Identifies the cycle at which the rate of fluorescence increase is maximal (peak of the second derivative). | Objective, software-automated, does not require threshold setting. | Standard assays with good reproducibility. |

| Cy0 (Fit Point Method) | Uses a non-linear regression model to fit the entire growth curve and extrapolate the crossing point. | Robust against noisy baselines and late-arising signals. | Noisy data or assays with variable efficiency. |

4. Experimental Protocol: RT-qPCR Run and Initial Data Processing Protocol 4.1: Standard SYBR Green I Assay for Gene Expression Objective: To quantify mRNA expression levels of a target biosynthetic gene relative to a reference gene.

Materials: